Table of Contents

Introduction

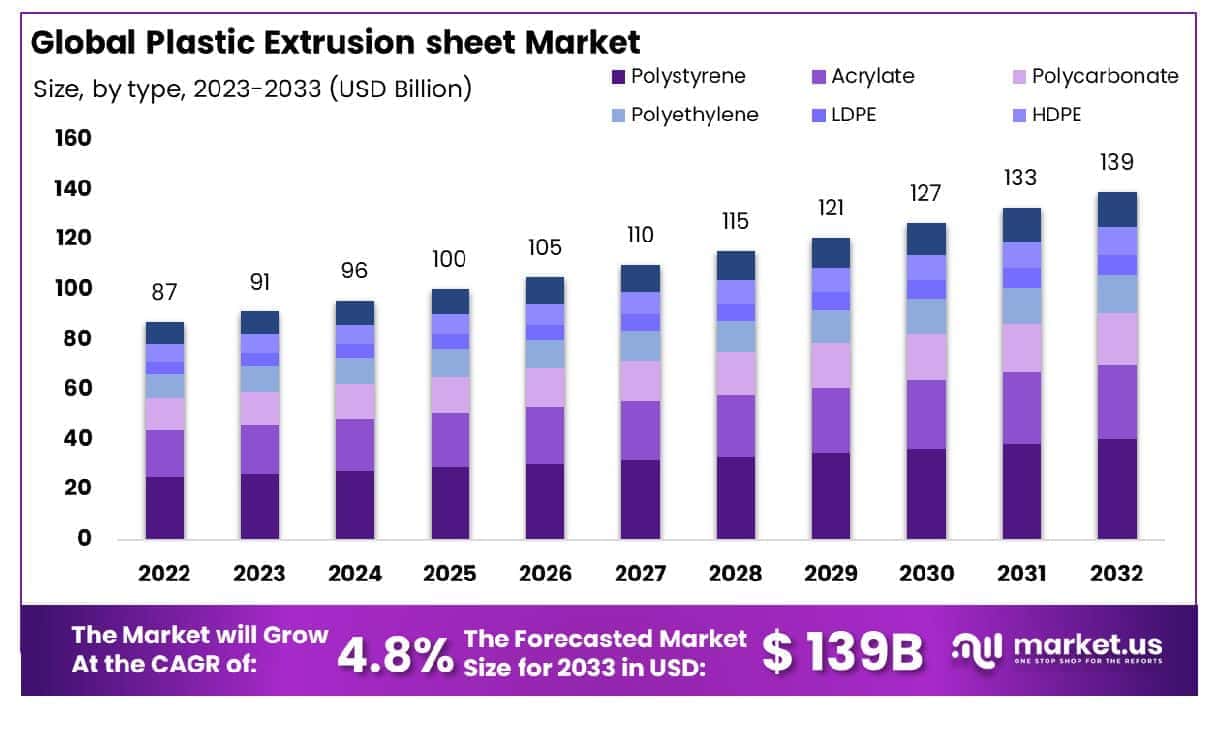

The Global Plastic Extrusion Sheet Market is projected to reach a value of approximately USD 139.0 billion by 2033, increasing from USD 87.0 billion in 2023. This represents a compound annual growth rate (CAGR) of 4.80% during the forecast period from 2024 to 2033.

The plastic extrusion sheet market involves the production and use of plastic sheets created through the extrusion process, where plastic is heated, melted, and forced through a die to form sheets of varying thicknesses. These sheets are then utilized in a wide range of applications, including packaging, construction, automotive, and electronics, due to their versatility, durability, and cost-effectiveness. The global plastic extrusion sheet market has witnessed steady growth, driven by the increasing demand for lightweight, durable, and recyclable materials.

Factors such as technological advancements in extrusion techniques, growing industrialization, and a heightened emphasis on sustainable practices have significantly contributed to market expansion. Additionally, the rise in consumer preference for eco-friendly alternatives has sparked innovations in the development of recyclable and biodegradable plastic sheets, providing new avenues for market growth.

The demand for plastic extrusion sheets is primarily influenced by their use in packaging, particularly in industries such as food and beverage, consumer goods, and healthcare. The demand is also rising in the construction sector for applications in insulation, window glazing, and building facades.

Furthermore, there is substantial opportunity within emerging markets, where rapid urbanization and industrial expansion are driving increased use of plastic products. Companies are focusing on technological innovations, such as the development of high-performance, low-maintenance plastic sheets, as a means to capture market share. With ongoing investments in R&D and the growing shift towards sustainable materials, the market is expected to experience sustained growth over the coming years.

Key Takeaways

- The global plastic extrusion sheet market is expected to grow from USD 87.0 billion in 2023 to USD 139.0 billion by 2033. The market is anticipated to expand at a CAGR of 4.80% from 2024 to 2033.

- Asia-Pacific holds the largest regional share at 33.7%, driven by growing industrial demand, especially in packaging and construction.

- Polystyrene is the dominant material type, accounting for 28.8% of the market share, attributed to its cost-effectiveness and versatility.

- Solid and textured structures make up 46.3% of the market, with solid sheets being widely used in packaging and construction.

- Virgin materials hold a significant market share of 74.6%, favored for their higher quality and durability in end-use applications.

- Packaging applications lead the market, contributing to 30.8% of demand, driven by the need for lightweight, durable, and cost-effective packaging solutions.

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2023) | USD 87 Billion |

| Forecast Revenue (2033) | USD 139 Billion |

| CAGR (2024-2033) | 4.80% |

| Segments Covered | By Type(Polystyrene, Acrylate, Polycarbonate, Polyethylene, Polypropylene, LDPE, HDPE), By Structure(Solid and Textured, Multiwall, Corrugated, Hollow), By Material(Virgin, Reprocessed), By Application(Packaging, Building & Construction, Signages, Automotive, Defence & Aerospace, Electrical & electronics, Medical) |

| Competitive Landscape | Owens Cornings, Corex Plastics Pty Ltd & MatraPlast, Karton S.p.A, DS Smith Plc, Arla Plast, MDI, Inteplast Group Corporation, Sefarin Group, Distriplast, Saudi Basic Industries Corporation, Wellplast AB |

Emerging Trends

- Increased Demand for Sustainable Materials: As industries and consumers alike are becoming more environmentally conscious, there is a growing trend towards the use of recycled and biodegradable plastics in extrusion processes. This demand for sustainable materials is pushing companies to innovate with eco-friendly extrusion sheets that meet regulatory and consumer expectations.

- Customization in Plastic Sheets: The demand for customized plastic extrusion sheets, including color, thickness, texture, and surface finish, is increasing. Manufacturers are focusing on providing tailored products to meet the specific needs of end-use applications across sectors such as packaging, construction, and automotive.

- Use of Advanced Technologies: Innovations in extrusion technologies, such as multi-layer and co-extrusion processes, are enabling the production of sheets with superior performance characteristics, including enhanced durability, flexibility, and resistance to heat and chemicals.

- Rise in Demand for Transparent Sheets: Plastic extrusion sheets that offer clear, transparent qualities are gaining traction, especially in industries such as packaging, signage, and display applications. These sheets offer aesthetic appeal while maintaining the durability of traditional plastic sheets.

- Integration of Smart Technologies: The plastic extrusion sheet market is beginning to see the integration of sensors and smart technologies into the extrusion process. This integration allows for real-time monitoring and quality control, leading to improved production efficiency and reduced material waste.

Top Use Cases

- Packaging Industry: Plastic extrusion sheets are extensively used in the packaging sector due to their lightweight, customizable nature, and durability. They are ideal for protective packaging solutions, including food and beverage containers, blister packs, and protective wraps.

- Construction Industry: Plastic sheets are commonly used in the construction industry for applications such as roofing, window glazing, cladding, and insulation. Their resistance to weather conditions, lightweight nature, and ease of installation make them a preferred material in modern construction projects.

- Automotive Industry: The automotive sector uses plastic extrusion sheets for a variety of applications, including interior panels, dashboards, and exterior body parts. Their ability to withstand harsh conditions while maintaining a high aesthetic appeal is a key driver for their adoption in automotive manufacturing.

- Signage and Display Applications: Plastic extrusion sheets are used extensively in the production of signage and display materials due to their transparency, ease of customization, and weather-resistant properties. These sheets are ideal for creating durable, eye-catching signage for both indoor and outdoor use.

- Electrical and Electronics: In the electrical and electronics industry, plastic extrusion sheets are employed for insulation purposes, protective casings, and as structural components in devices and machines. Their insulating properties and resistance to electrical currents make them an essential material in this sector.

Major Challenges

- Environmental Impact: Despite the growing interest in sustainable materials, plastic extrusion sheets are still largely derived from petroleum-based resources. The environmental concerns related to plastic waste and disposal remain a significant challenge for the market.

- Raw Material Cost Volatility: Fluctuations in the cost of raw materials, particularly petroleum derivatives, can disrupt production schedules and increase the overall cost of plastic extrusion sheets. This volatility creates uncertainty for manufacturers and can affect pricing stability in the market.

- Technological Limitations: While there have been advancements in extrusion technologies, challenges remain in scaling up production processes for more complex and innovative sheet designs. Ensuring consistent product quality across different production runs also continues to be a hurdle.

- Regulatory Pressures: Stringent regulations surrounding the environmental impact of plastic products, especially in the European Union and North America, are forcing manufacturers to adapt. Compliance with these regulations often requires significant investment in new technologies and materials.

- Competition from Alternative Materials: The increasing adoption of alternative materials, such as bio-based plastics, glass, and metal composites, poses a competitive threat to traditional plastic extrusion sheets. These alternatives may offer superior performance in specific applications and are being promoted as more environmentally friendly.

Top Opportunities

- Expansion in Emerging Markets: As emerging economies continue to develop their infrastructure, there is an increasing demand for plastic extrusion sheets in construction, automotive, and packaging applications. Expanding into these markets presents a significant growth opportunity for manufacturers.

- Development of Recyclable and Eco-Friendly Sheets: The shift toward sustainability presents opportunities for companies to innovate by developing fully recyclable or biodegradable plastic extrusion sheets. This can attract eco-conscious customers and help companies align with global sustainability trends.

- Technological Advancements in Production: Ongoing advancements in extrusion technology, such as 3D extrusion and multi-layer processes, open new possibilities for creating more durable, lightweight, and customizable sheets. These innovations can enhance the performance and versatility of plastic extrusion sheets across industries.

- Collaborations and Strategic Partnerships: Companies can explore collaborations with material suppliers, technology providers, and end-users to create integrated solutions that address specific market needs. Such partnerships can provide access to new markets and foster innovation in product development.

- Increase in Demand for High-Performance Sheets: The need for plastic extrusion sheets that can withstand extreme temperatures, chemicals, and other harsh conditions is growing. This trend presents an opportunity for manufacturers to focus on high-performance materials for specialized applications in aerospace, military, and industrial sectors.

Key Player Analysis

The global plastic extrusion sheet market in 2024 is characterized by the presence of key industry players such as Owens Corning, Corex Plastics Pty Ltd & MatraPlast, and Karton S.p.A, which continue to drive market innovation and growth. Owens Corning, with its diverse portfolio and emphasis on sustainable solutions, is well-positioned to capitalize on the increasing demand for eco-friendly materials.

Corex Plastics Pty Ltd & MatraPlast, renowned for their expertise in high-quality extrusion products, maintain a strong competitive edge in various industrial applications. Karton S.p.A, leveraging its advanced technology in plastic sheet production, holds a significant share in Europe. Other notable players, including DS Smith Plc, Arla Plast, and Inteplast Group Corporation, continue to innovate with product offerings tailored to specific market segments, such as packaging and automotive. Saudi Basic Industries Corporation (SABIC) stands out with its vast production capabilities and global reach, making it a dominant force in the market’s growth trajectory.

Top Market Key Players

- Owens Cornings

- Corex Plastics Pty Ltd & MatraPlast

- Karton S.p.A

- DS Smith Plc

- Arla Plast

- MDI

- Inteplast Group Corporation

- Sefarin Group

- Distriplast

- Saudi Basic Industries Corporation

- Wellplast AB

Regional Analysis

Asia-Pacific Region Dominating the Plastic Extrusion Sheet Market with the Largest Market Share (33.7%) in 2024

The Asia-Pacific region is poised to retain a dominant position in the plastic extrusion sheet market, commanding a substantial share of 33.7% in 2024. Valued at approximately USD 29.3 billion, the region is expected to continue its leadership due to a combination of factors, including rapid industrialization, expanding manufacturing sectors, and increasing demand from key industries such as packaging, automotive, and construction. The market’s growth can be attributed to the growing production capacities in countries like China, India, and Japan, where plastic extrusion sheets are increasingly used in packaging materials, automotive components, and building applications.

Furthermore, the region benefits from the presence of numerous large-scale manufacturers and suppliers, which further solidifies its market dominance. With the ongoing advancements in extrusion technologies and the rising preference for lightweight, durable materials, the Asia-Pacific market is forecasted to maintain its leading share in the global plastic extrusion sheet market over the coming years.

Recent Developments

- In February 2025, GlobalTech Industries, a leading manufacturer of advanced plastics and materials, revealed that it has entered into an agreement to acquire a production facility in Tijuana, Mexico, from PolyPro Solutions. This facility, specializing in the production of high-performance polycarbonate sheets, will enable GlobalTech to expand its product portfolio for applications in automotive, construction, and consumer electronics sectors.

- In 2025, BioChem Enterprises, a prominent chemical solutions provider, is set to introduce a new line of eco-friendly biopolymer resins at the Global Materials Conference. These innovative resins are designed to provide superior durability and chemical resistance for medical device manufacturing, offering a more sustainable alternative to traditional polymers. The biopolymer resins aim to reduce the carbon footprint by up to 35%, aligning with the growing demand for greener materials in healthcare products.

- In January 2025, Apex Materials announced a strategic partnership with EcoPlastics to enhance its sustainable product offerings across Europe. Starting in the first quarter of 2025, Apex Materials will introduce a wider range of eco-friendly thermoplastic elastomers (TPEs) and thermoplastic vulcanizates (TPVs) to meet the increasing demand for environmentally responsible materials. This collaboration strengthens Apex’s position in the automotive, industrial, and consumer product markets, offering customers more sustainable, high-performance material solutions.

- In March 2025, GreenChem Corp, a leader in polymer technology, unveiled plans to construct a new research and development facility in Singapore to focus on the development of advanced biodegradable plastics. This facility is expected to support GreenChem’s efforts in creating innovative solutions for packaging and agricultural applications, meeting the growing demand for sustainable materials in Southeast Asia.

Conclusion

The global plastic extrusion sheet market is poised for steady growth driven by increasing demand across key industries such as packaging, construction, automotive, and electronics. Technological advancements, particularly in extrusion techniques and material innovation, are enhancing the performance and versatility of plastic sheets, while the rising demand for sustainable, eco-friendly materials presents new opportunities. Despite challenges related to environmental impact, raw material cost fluctuations, and regulatory pressures, manufacturers are focusing on developing high-performance, customizable, and recyclable plastic sheets to meet evolving market needs. With strong regional demand, particularly in Asia-Pacific, and continuous innovation, the plastic extrusion sheet market is well-positioned to expand in the coming years, offering significant growth potential for both established players and new entrants.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)