Table of Contents

Introduction

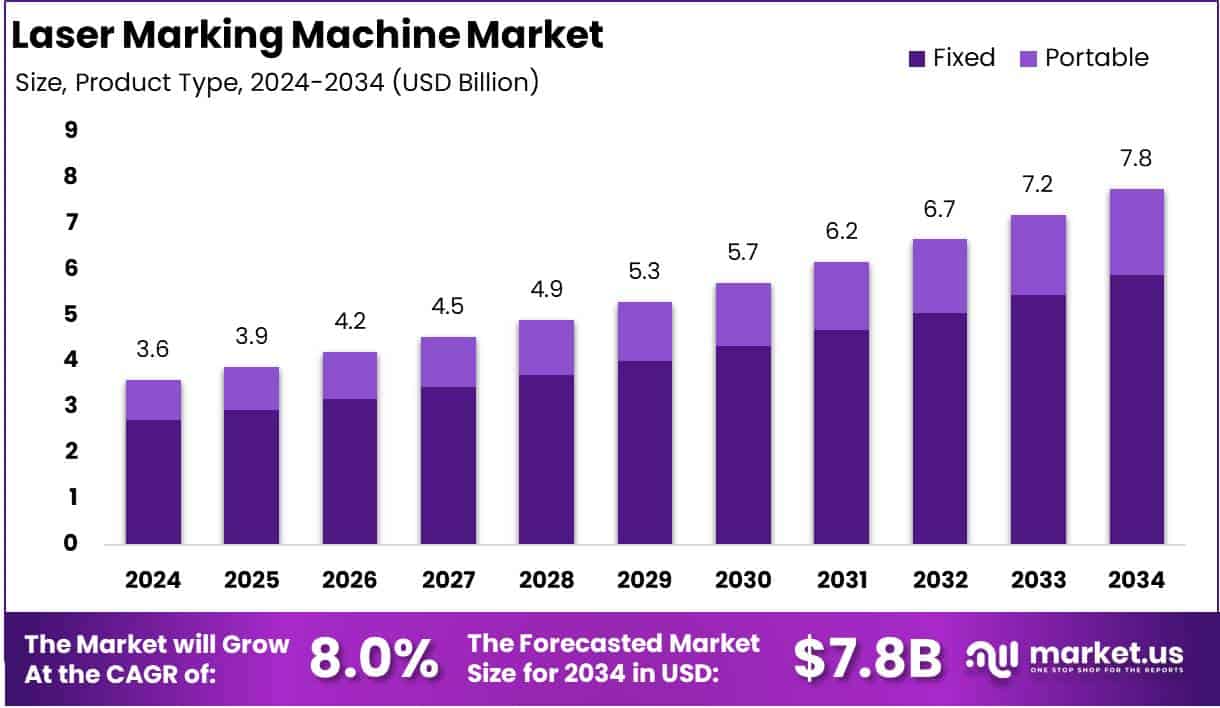

New York, NY – April 03, 2025 – The Global Laser Marking Machine Market is projected to reach a value of approximately USD 7.8 billion by 2034, up from USD 3.6 billion in 2024. This growth is expected to occur at a compound annual growth rate (CAGR) of 8.0% during the forecast period from 2025 to 2034.

Laser marking machines are advanced systems that use laser technology to engrave, etch, or mark materials with high precision and speed. These machines employ focused laser beams to create permanent markings on a wide range of materials, including metals, plastics, ceramics, and more. Laser marking is widely used across various industries such as automotive, electronics, healthcare, and packaging due to its accuracy, speed, and non-contact nature, ensuring no material degradation.

The laser marking machine market refers to the global industry focused on the manufacturing, distribution, and application of laser-based marking equipment. The market has experienced significant growth due to increasing demand for precise, high-quality markings in industries where traceability, branding, and compliance with regulatory standards are critical. Growth drivers for the market include technological advancements in laser sources, miniaturization of equipment, and the rising adoption of automation in manufacturing processes.

Furthermore, there is an increasing preference for laser marking over traditional marking techniques, such as ink-based and mechanical methods, due to its environmental advantages and reduced maintenance requirements. The demand for laser marking machines is primarily fueled by the growing need for product identification, serialization, and branding across sectors like automotive, electronics, medical devices, and consumer goods.

Opportunities for market expansion exist in emerging markets where industrialization is rapidly increasing, and industries are increasingly adopting automation and smart manufacturing technologies. The growing trend of eco-friendly solutions and sustainability in production further contributes to the opportunities for laser marking machines as they do not generate waste or require chemicals, making them ideal for sustainable production processes

Key Takeaways

- The global laser marking machine market is anticipated to expand from USD 3.6 billion in 2024 to USD 7.8 billion by 2034, reflecting a CAGR of 8.0% from 2025 to 2034.

- Fiber lasers lead the market with a 39.4% share, highlighting their key role in driving market demand.

- 2D laser marking machines dominate the market with a 65.1% share, preferred for their versatility in marking flat surfaces and their cost-effectiveness compared to 3D alternatives.

- Fixed laser marking machines hold a significant 75.8% share of the market, due to their stability and precision, making them ideal for permanent marking tasks in manufacturing environments.

- Engraving is the most common application of laser marking machines, commanding a 35.6% market share.

- Metal materials make up 42.6% of the laser marking market, with strong demand driven by industries such as automotive, aerospace, and manufacturing.

- The machine tool industry is the largest consumer of laser marking machines, representing 26.8% of the market share.

- Asia-Pacific is the dominant region, holding 38.3% of the global market in 2024, valued at approximately USD 1.3 billion.

Request A Sample Copy Of This Report at https://market.us/report/laser-marking-machine-market/request-sample/

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2024) | USD 3.6 Billion |

| Forecast Revenue (2034) | USD 7.8 Billion |

| CAGR (2025-2034) | 8.0% |

| Segments Covered | By Type(Fiber Laser, Diode Laser, Solid-state Laser, CO2 Laser, UV Laser, Others), By Machine Type(2D, 3D), By Product Type(Fixed, Portable), By Application(Ablation, Annealing, Carbonizing, Foaming, Engraving, Others), By Material(Metal, Glass, Plastics, Others), By End-Use(Machine Tool, Automotive, Electronics & Semiconductor, Defense & Aerospace, Healthcare, Packaging & Labeling, Others) |

| Competitive Landscape | Danaher Corporation, IPG Photonics Corporation, Trumpf GmbH + Co. KG, Keyence Corporation, Novanta Inc., Gravotech Marking SAS, Trotec Laser GmbH, LaserStar Technologies Corporation, TYKMA Electrox, Inc., Telesis Technologies, Inc., Epilog Laser, LLC, MECCO, LLC, Huagong Tech Co., Ltd., The 600 Group PLC, Videojet Technologies, Inc. |

Emerging Trends

- Integration with Industry 4.0: Laser marking machines are increasingly being integrated with smart manufacturing systems, enabling real-time data collection and process optimization.

- Miniaturization: Advancements in laser technology have led to the development of compact laser marking systems capable of marking micro-scale features, catering to industries such as electronics and medical devices.

- Customization and Personalization: There is a growing demand for customized products, prompting the use of laser marking machines for personalized engravings and variable data printing, especially in consumer goods and luxury items.

- High-Speed Processing: To meet the demands of high-throughput manufacturing, laser marking machines are being developed with increased processing speeds, reducing cycle times and enhancing productivity.

- Environmentally Friendly Marking: Laser marking offers a non-contact, chemical-free marking process, aligning with the industry’s shift towards sustainable and eco-friendly manufacturing practices.

Top Use Cases

- Product Identification: Laser marking is extensively used for engraving serial numbers, barcodes, and QR codes on products, ensuring traceability and authenticity across various sectors.

- Branding and Decoration: Manufacturers utilize laser marking to create intricate logos and decorative patterns on products, enhancing brand recognition and aesthetic appeal, particularly in consumer electronics and automotive parts.

- Medical Device Marking: Laser marking machines are employed to mark medical instruments and implants with essential information, adhering to regulatory standards and ensuring patient safety.

- Electronic Component Marking: In the electronics industry, laser marking is used to label components with part numbers and specifications, facilitating assembly and maintenance processes.

- Packaging Verification: Laser marking systems are applied in packaging to print expiration dates, batch numbers, and other variable data, ensuring compliance with industry regulations and enhancing supply chain management.

Major Challenges

- Material Compatibility: Achieving optimal marking quality on diverse materials remains challenging, as laser interactions vary significantly across different substrates.

- System Integration: Integrating laser marking systems into existing production lines requires significant customization and poses compatibility challenges with legacy equipment.

- Cost of Ownership: High initial investment and maintenance costs associated with advanced laser marking systems can be a barrier, especially for small and medium-sized enterprises.

- Technical Expertise: Operating and maintaining laser marking machines necessitates specialized knowledge, leading to a potential skills gap and increased training requirements.

- Regulatory Compliance: Ensuring that laser marking processes meet industry-specific regulatory standards demands continuous monitoring and adaptation, posing compliance challenges.

Top Opportunities

- Expansion in Emerging Markets: Rapid industrialization in regions such as Asia-Pacific presents significant growth opportunities for laser marking machine manufacturers.

- Technological Advancements: Investments in research and development can lead to innovations in laser marking technologies, offering enhanced capabilities and opening new application areas.

- Adoption in Automotive Industry: The automotive sector’s focus on lightweight materials and complex designs creates a demand for precise laser marking solutions.

- Growth in Consumer Electronics: The proliferation of consumer electronic devices drives the need for high-quality marking solutions for branding and regulatory compliance.

- Sustainability Initiatives: The trend towards eco-friendly manufacturing processes aligns with the adoption of laser marking technologies, which offer non-toxic and waste-free operations

Key Player Analysis

The global laser marking machine market features key players that contribute to its expansion through innovation and advanced technologies. Danaher Corporation, a major player, offers a broad range of laser marking solutions, enhancing precision across various industries.

IPG Photonics Corporation stands out with its high-performance fiber lasers, providing superior marking capabilities for diverse applications. Trumpf GmbH + Co. KG is renowned for integrating advanced laser technology with user-friendly systems, catering to both standard and customized marking needs. Keyence Corporation excels with its high-speed, high-resolution laser markers, which are widely used in modern manufacturing processes.

Other significant players include Novanta Inc., known for its precision laser solutions, and Gravotech Marking SAS, which offers reliable, versatile systems for marking various materials. Trotec Laser GmbH focuses on efficiency and quality, while LaserStar Technologies Corporation delivers advanced marking systems with exceptional precision. The competition from TYKMA Electrox, Telesis Technologies, Epilog Laser, and others ensures continuous innovation and drives the market forward, meeting the evolving needs of industries worldwide.

Top Market Key Players

- Danaher Corporation

- IPG Photonics Corporation

- Trumpf GmbH + Co. KG

- Keyence Corporation

- Novanta Inc.

- Gravotech Marking SAS

- Trotec Laser GmbH

- LaserStar Technologies Corporation

- TYKMA Electrox, Inc.

- Telesis Technologies, Inc.

- Epilog Laser, LLC

- MECCO, LLC

- Huagong Tech Co., Ltd.

- The 600 Group PLC

- Videojet Technologies, Inc.

Purchase The Full Report Now at https://market.us/purchase-report/?report_id=17711

Regional Analysis

Asia-Pacific – Laser Marking Machine Market with Largest Market Share of 38.3% in 2024

The Asia-Pacific region is expected to dominate the global laser marking machine market, accounting for a significant market share of 38.3% in 2024, with an estimated market value of USD 1.3 billion. The region’s growth can be attributed to its rapidly advancing manufacturing and industrial sectors, particularly in countries like China, Japan, and India.

These nations have made substantial investments in automation and advanced technologies, driving demand for laser marking machines across various industries, including automotive, electronics, and packaging. Additionally, the strong presence of key market players in Asia-Pacific, coupled with the region’s favorable manufacturing environment, has contributed to its leadership in the global market.

Furthermore, the increasing adoption of laser marking machines in the electronics and automotive sectors, due to their precision, high speed, and cost-effectiveness, further supports the region’s market dominance.

As a result, Asia-Pacific is expected to maintain its stronghold as the largest market for laser marking machines, with sustained growth driven by continuous technological advancements and expanding industrial applications. The region’s contribution to the global market will remain critical in shaping the future of the laser marking machine industry.

Recent Developments

- In January 2023, Thorlabs announced its decision to acquire JML Optical Industries, a renowned custom designer and manufacturer of precision optics. JML, established in 1972, operates a 70,000-square-foot facility dedicated to the creation of various optical components, including spherical, aspherical, and cylindrical lenses, along with multi-element optical devices. This acquisition is expected to finalize by the end of January 2023, expanding Thorlabs’ capabilities in optics design and production.

- In June 2023, Coherent Corp. introduced its latest innovation, the Matrix nanosecond pulsed UV lasers. These ultralow-cost lasers are designed for high-contrast marking applications across several industries, including consumer goods, electronics, home appliances, and packaging. Coherent’s new lasers aim to provide efficient and precise solutions for marking, further solidifying its leadership in advanced laser processing technologies.

- In November 2024, Laser Photonics Corporation (LPC) finalized its acquisition of Control Micro Systems, Inc. (CMS), enhancing its position in the global laser market. This strategic acquisition allows LPC to expand its offerings in industrial laser systems, particularly in the growing pharmaceutical equipment sector, known for its stability and demand. The deal strengthens LPC’s presence in material processing applications and opens new growth opportunities in the healthcare and pharmaceutical industries.

- In May 2024, Videojet Technologies introduced two new laser marking systems, the Videojet 3350 and the Videojet 3350 Smart Focus 30-watt CO2 lasers, designed to meet the high-performance demands of manufacturers. These systems are capable of producing sharp, complex codes at high speeds and are suitable for industries such as food and beverage, cosmetics, pharmaceuticals, and packaging. The new models offer enhanced flexibility in font, code, and graphic options, providing an effective marking solution for various applications.

Conclusion

The sustainable fashion market is witnessing notable growth, driven by increasing consumer awareness of environmental and ethical issues. This shift towards eco-friendly materials, ethical production, and sustainable consumption is reshaping the industry. As more consumers prioritize sustainability, brands are adapting by offering eco-conscious alternatives. However, the sector still faces challenges such as higher production costs and competition from fast fashion. Continued innovation and industry collaboration will be crucial to further advancing sustainable practices and meeting consumer demand for environmentally responsible fashion.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)