Table of Contents

Introduction

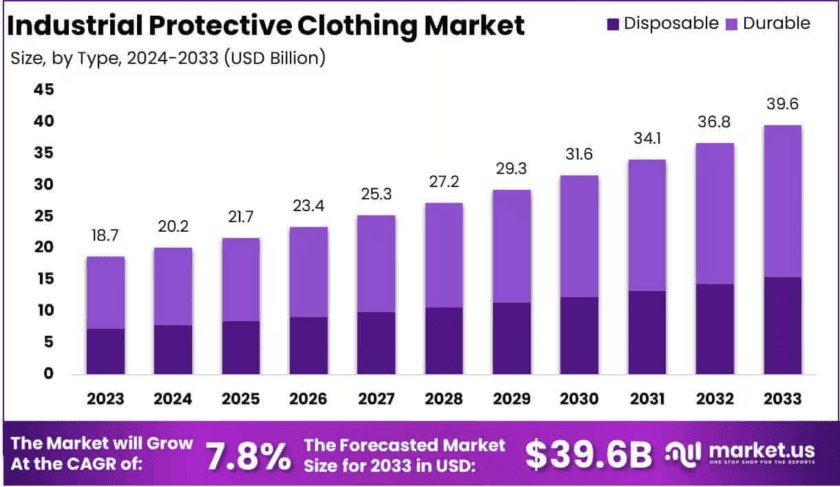

The Global Industrial Protective Clothing Market is projected to reach approximately USD 39.6 billion by 2033, up from USD 18.7 billion in 2023, growing at a compound annual growth rate (CAGR) of 7.8% from 2024 to 2033.

Industrial protective clothing refers to specialized garments designed to safeguard workers in industrial settings from hazardous materials, extreme temperatures, chemical exposure, electrical risks, and physical injuries. The industrial protective clothing market encompasses a wide array of products such as gloves, helmets, coveralls, boots, and high-visibility vests, each tailored for specific work environments. This market has seen robust growth driven by stringent safety regulations, a growing emphasis on worker welfare, and increased industrial activities across sectors like manufacturing, construction, and chemicals.

Rising awareness of occupational health and safety, along with advancements in material science, is further fueling the demand for more comfortable and durable protective gear. Additionally, the expansion of industries in emerging markets presents substantial opportunities for market players to develop region-specific solutions. The growing trend towards sustainability is also creating opportunities for eco-friendly and recyclable protective clothing, which may attract environmentally conscious businesses and consumers alike.

Key Takeaways

- The Global Industrial Protective Clothing Market is expected to grow from USD 18.7 billion in 2023 to USD 39.6 billion by 2033, driven by a 7.8% CAGR.

- Durable protective clothing holds the largest market share at 61%, mainly due to its widespread use in high-risk industries like oil & gas and manufacturing.

- Heat & flame protection leads the market with a 34% share, driven by demand from sectors such as oil & gas, metalworking, and firefighting.

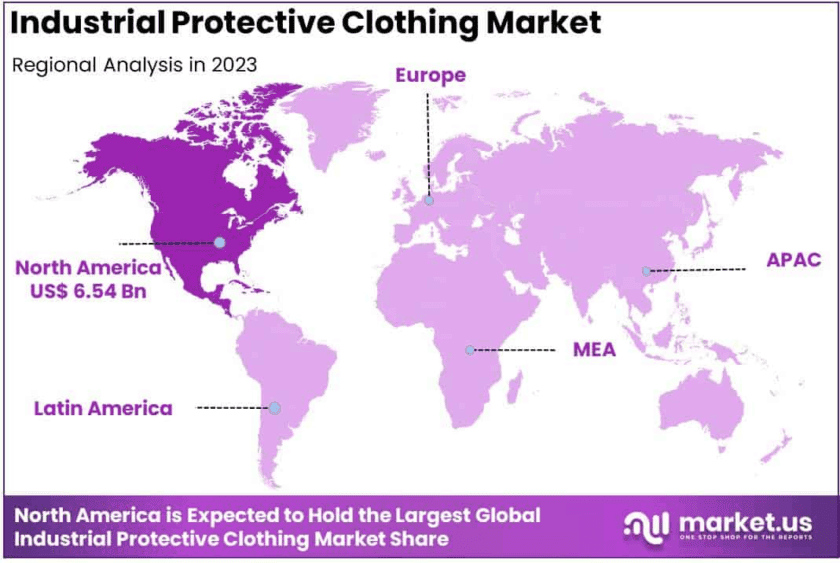

The healthcare sector accounts for 25% of the market share, propelled by increased demand for personal protective equipment (PPE) in response to ongoing infection control measures. - North America dominates with a 35% market share, supported by stringent safety regulations and high adoption of advanced protective apparel.

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2023) | USD 18.7 Billion |

| Forecast Revenue (2033) | USD 39.6 Billion |

| CAGR (2024-2033) | 7.8% |

| Segments Covered | By Type (Disposable, Durable), By Application (Heat & Flame Protection, Chemical Defending Protective Clothing, Mechanical Protective Clothing, Others ), By End-use (Healthcare, Manufacturing, Chemicals, Construction, Food Oil and Gas, Others) |

| Competitive Landscape | W. L. Gore & Associates, Inc., Honeywell International Inc., Lakeland Industries, Inc., PBI Performance Products, Inc., Kimberly-Clark, Bennett Safetywear Ltd., Ansell Ltd, Teijin Limited, Australian Defense Apparel, Workwear Outfitters, LLC, DuPont, TenCate Protective, Other Key Players |

Industrial Protective Clothing Statistics

- There were 2,705 chemical-related injuries and illnesses in the mining sector, primarily from contact with acids and alkalis.

- Proper personal protective equipment (PPE) usage at construction sites can reduce occupational injuries and diseases by 37.6%.

- The construction sector is responsible for 46.1% of all fatal falls, slips, and trips.

- Only 16% of workers who experienced head injuries wore hard hats.

- Among 770 workers who sustained injuries, just 1% were using face protection.

- Only 23% of workers who suffered foot injuries were wearing safety shoes or boots.

- Eye protection was worn by only 40% of workers who had eye injuries.

- The pharmaceutical manufacturing sector reported 1.6 nonfatal occupational injuries per 100 full-time workers in 2020.

Emerging Trends

- Sustainability and Eco-Friendly Materials: Industrial protective clothing is increasingly being manufactured using sustainable, eco-friendly materials. The demand for clothing made from biodegradable fabrics, recycled fibers, and non-toxic dyes is rising due to growing environmental awareness. Companies are investing in research to develop clothing solutions that reduce the environmental impact of production, helping to meet sustainability goals within industries like manufacturing, construction, and chemicals.

- Smart Fabrics and Wearable Technology: There’s a rising trend in integrating wearable technology into protective clothing. Smart fabrics are being developed to monitor workers’ vital signs, track environmental conditions, and provide real-time feedback. Sensors embedded in the clothing can alert workers to dangerous exposure levels or even detect fatigue, improving safety protocols and reducing workplace injuries.

- Customizable PPE Solutions: Personal protective equipment (PPE) is moving towards more customizable options to fit specific industry needs. For example, high-visibility clothing for construction workers is being designed with adjustable reflective materials, offering better adaptability in different lighting and environmental conditions. Similarly, heat-resistant clothing for industrial workers is becoming more tailored to individual body types and activity levels.

- Anti-Microbial and Anti-Viral Protection: Given the recent focus on health and hygiene, there is a growing trend toward incorporating antimicrobial and antiviral coatings in protective clothing. This helps prevent the growth of bacteria and viruses, which is particularly important in industries like healthcare, food processing, and pharmaceuticals, where workers may be exposed to contaminants. The fabric can help reduce the transmission of harmful pathogens, contributing to a safer work environment.

- Compliance with Stricter Safety Standards: As safety regulations become stricter across various industries, protective clothing is evolving to meet more demanding standards. New regulatory guidelines are pushing manufacturers to enhance the durability and effectiveness of protective clothing. This includes offering improved flame-resistant, chemical-resistant, and waterproof materials to ensure better compliance with international safety standards and regulations.

Top Use Cases

- Construction Sites: Workers in construction face risks such as falling objects, sharp materials, and electrical hazards. Protective clothing, including hard hats, high-visibility vests, and sturdy boots, provides a layer of defense. According to industry estimates, around 50% of all workplace injuries in construction are preventable with the correct protective gear.

- Manufacturing and Heavy Industry: In manufacturing plants, workers are often exposed to heat, chemicals, and machinery. Industrial protective clothing such as flame-resistant suits, chemical-resistant gloves, and safety goggles plays a critical role in preventing burns, exposure to harmful substances, and eye injuries. The use of this protective clothing is estimated to reduce workplace injuries by as much as 35%.

- Laboratories and Cleanrooms: In environments like laboratories and cleanrooms, workers handle hazardous chemicals or work in sterile environments. Specialized clothing such as lab coats, gloves, and masks helps prevent contamination and exposure to harmful substances. This type of protective gear is essential in pharmaceutical production, research facilities, and food processing industries.

- Oil and Gas Industry: Workers in the oil and gas sector face extreme temperatures, flame risks, and exposure to toxic chemicals. Protective clothing designed for this sector includes heat-resistant and flame-retardant suits, chemical-resistant boots, and gloves, which safeguard against injuries. According to reports, the risk of fire-related incidents can be cut by over 40% with proper PPE.

- Mining Operations: Miners are exposed to several risks, including falling rocks, extreme temperatures, and toxic gases. Protective clothing such as reinforced boots, helmets, and specialized suits is essential in reducing these risks. The implementation of full-body protection can reduce fatal accidents in mining by up to 30%.

Major Challenges

- Cost of High-Performance Materials: High-quality industrial protective clothing that offers advanced protection (such as heat resistance, chemical resistance, or smart features) tends to be expensive to produce. This creates a barrier for many small- and medium-sized businesses that may struggle to afford top-tier PPE solutions. According to industry reports, the cost of advanced protective clothing can be 40-60% higher than basic alternatives.

- Comfort and Mobility Issues: Many protective clothing solutions prioritize safety over comfort, leading to worker complaints about stiffness, discomfort, and restricted mobility. This can reduce overall productivity and lead to workers removing PPE in hazardous situations, increasing the risk of injuries. Manufacturers are working to balance comfort and protection, but achieving this is still a challenge.

- Durability and Wear-and-Tear: Industrial protective clothing, especially in harsh environments like manufacturing and construction, can suffer from wear-and-tear that reduces its effectiveness over time. Frequent replacement of worn-out clothing increases operational costs. In some cases, protective gear only remains effective for a few months, especially in high-abrasion environments.

- Lack of Awareness and Training: Many workers do not fully understand the importance of wearing industrial protective clothing or the correct ways to maintain it. Improper use or neglecting safety gear due to insufficient training leads to higher injury rates. Reports indicate that up to 20% of workplace accidents occur because employees either fail to wear PPE or use it incorrectly.

- Compliance with Changing Regulations: Keeping up with evolving safety standards and regulations is an ongoing challenge for manufacturers and businesses. In many regions, safety regulations are becoming stricter, and companies must ensure that their protective clothing adheres to these updated standards. Failure to comply can result in penalties and increased liability, making the constant revision of products and processes an ongoing challenge.

Top Opportunities

- Integration of Smart Technologies: There is a growing demand for smart wearable technology in industrial protective clothing, providing opportunities for innovation. Wearables that monitor environmental conditions, track heart rates, or even detect chemical exposure are expected to see significant adoption. As industries like construction, oil, and gas embrace these technologies, market opportunities for smart PPE are expanding.

- Increased Focus on Worker Wellness: Companies are increasingly focusing on worker wellness, not just safety. The rise in workplace wellness programs creates demand for protective clothing that is designed to be more comfortable, breathable, and ergonomic. Apparel that reduces strain, increases comfort, and supports long working hours will see growth, particularly in sectors with heavy labor demands.

- Expansion in Emerging Markets: As industrialization increases in emerging markets, the need for industrial protective clothing is growing. Countries in Asia, Africa, and Latin America are seeing more construction, manufacturing, and mining projects, all of which require protective gear. The market for industrial protective clothing is expected to expand significantly in these regions, driven by the need for compliance with global safety standards.

- Rise in Hazardous Materials Handling: As industries dealing with hazardous materials such as chemicals, toxic gases, and biohazards grow, there is a heightened demand for specialized protective clothing. The chemical, pharmaceutical, and waste management sectors are expected to drive growth in this area, with specialized PPE that ensures the safety of workers dealing with harmful substances.

- Sustainability and Eco-Conscious Manufacturing: The trend toward sustainability in the industrial sector presents opportunities for manufacturers of protective clothing to produce environmentally friendly options. Clothes made from recycled materials, biodegradable fabrics, or those designed for longer durability to reduce waste are gaining traction. Sustainability in production processes, such as using non-toxic dyes or reducing water usage, is a growing opportunity for companies to innovate and align with global environmental goals.

Regional Analysis

North America Leading Region in the Industrial Protective Clothing Market with the Largest Market Share (35%)

North America dominates the global Industrial Protective Clothing market, holding a substantial market share of 35% in 2023, valued at approximately USD 6.54 billion. The region’s leadership in this market is driven by stringent occupational safety regulations, a robust industrial base, and increasing demand for protective gear across sectors such as manufacturing, oil and gas, chemicals, and construction.

The adoption of advanced protective materials, coupled with growing concerns around worker safety and compliance, has further solidified North America’s position. Additionally, key market players in the region are continuously innovating to enhance the functionality and comfort of protective clothing, contributing to sustained market growth. The U.S., in particular, remains a major contributor due to its large industrial sector and regulatory frameworks that enforce safety standards, ensuring a steady demand for industrial protective apparel.

Recent Developments

- In Sept. 10, 2024, Milliken & Company revealed that Polartec® Power Shield™ Pro, a cutting-edge waterproof fabric, won the prestigious 2024 R&D 100 Award. This achievement underscores Milliken’s continued leadership in textile technology, highlighting the impact of Polartec in advancing material performance.

- In July 2, 2024, Ansell Limited (ASX: ANN) announced it had successfully acquired Kimberly-Clark’s Personal Protective Equipment (KCPPE) division. This acquisition strengthens Ansell’s position in the protection solutions market, enhancing its global product offerings and service capabilities.

- In Aug. 28, 2024, MSA Safety, Inc. (NYSE: MSA) was honored as a 2024 Outstanding Corporate Innovator (OCI) by the Product Development and Management Association (PDMA). This recognition celebrates MSA’s company-wide commitment to innovation and its efforts in advancing worker safety across industries globally. This is the second time MSA has earned this prestigious accolade.

- In Dec. 16, 2024, Lakeland Fire + Safety (NASDAQ: LAKE) completed the acquisition of Veridian, a U.S.-based company, in an all-cash deal valued at $25 million. This strategic acquisition enhances Lakeland’s product portfolio and strengthens its position in the global protective clothing market.

- In Feb. 21, 2024, Honeywell introduced augmented reality to its Immersive Field Simulator (IFS) platform, which offers digital twin-based training for industrial workers. The new Immersive Equipment Views application provides on-demand training through augmented reality on iPads, giving workers the flexibility to train from anywhere in the field.

- In Nov. 6, 2023, DuPont announced the winners of the 2023 Nomex® Innovation Award at the A+A show in Düsseldorf, Germany. The winning products, created with DuPont™ Nomex® materials, set new standards in worker protection, design, and ergonomics in challenging industrial environments.

Conclusion

The Industrial Protective Clothing market is poised for significant growth as industries continue to prioritize worker safety and regulatory compliance. With increasing adoption of advanced materials, smart technologies, and sustainable practices, the market is evolving to meet the diverse needs of various sectors, from construction and manufacturing to healthcare and oil and gas. Emerging trends like wearable technology, customizable PPE, and eco-friendly solutions are set to drive innovation, while rising demand in developing markets presents new opportunities for expansion. Despite challenges such as high costs and durability concerns, the market’s overall trajectory remains positive, underpinned by a global push for enhanced safety standards and worker wellness.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)