Table of Contents

Introduction

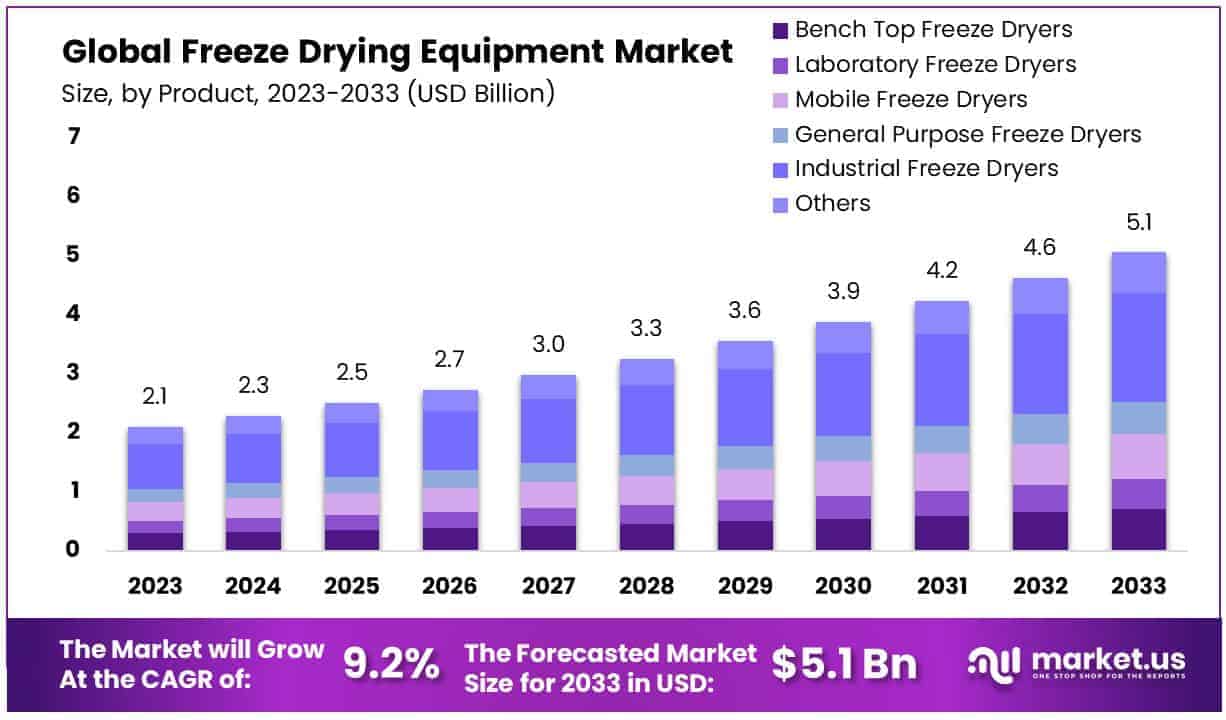

The Freeze Drying Equipment Market is projected to expand from USD 2.1 billion in 2023 to approximately USD 5.1 billion by 2033, advancing at a compound annual growth rate (CAGR) of 9.20% over the forecast period from 2024 to 2033.

Freeze drying equipment, also known as lyophilization equipment, is utilized in the process of removing moisture from a product after it is frozen and placed under a vacuum, allowing the ice to change directly from solid to vapor without passing through a liquid phase. This technique is widely used in pharmaceutical and biotechnology manufacturing, food and beverage processing, and technological applications due to its ability to preserve the integrity and functionality of heat-sensitive materials.

The freeze-drying equipment market is experiencing significant growth, driven by the rising demand for preserved food and pharmaceuticals, where the extension of shelf life and ease of transport are critical. The increasing adoption of automation and technology in lyophilization systems is also contributing to market expansion. Furthermore, the market is expected to benefit from growing investments in biotechnology and healthcare research, as well as rising demand from emerging economies where there is an increasing need for longer-lasting perishable products. The growth in this market presents substantial opportunities for manufacturers to innovate and develop more efficient, scalable freeze drying solutions that cater to the diverse needs of different industries, thereby boosting the market’s potential in the coming years.

Key Takeaways

- The Freeze Drying Equipment Market market is projected to grow from USD 2.1 billion in 2023 to USD 5.1 billion by 2033, with a compound annual growth rate (CAGR) of 9.20% from 2024 to 2033.

- Industrial Freeze Dryers hold the largest segment share at 36.5%, primarily supporting the pharmaceutical and food industries for large-scale preservation needs.

- The Food Processing sector is the dominant application area, accounting for 35.2% of the market. This is driven by increasing consumer demand for preserved foods that maintain nutritional value.

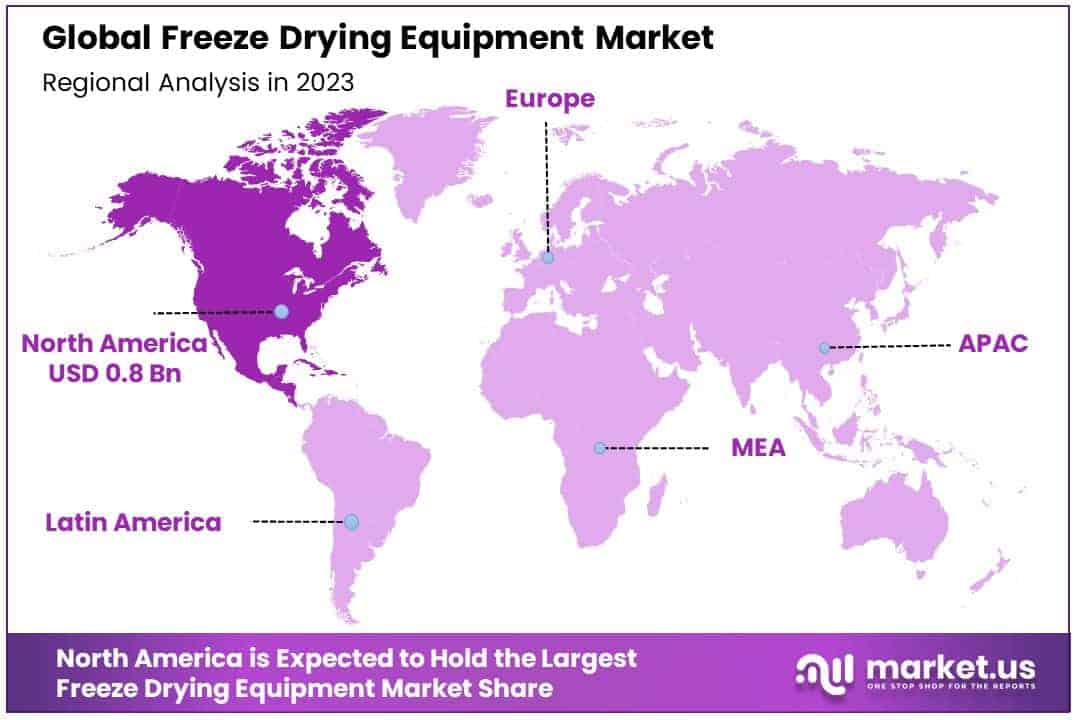

- Geographically, North America leads the market with a 37.1% share, fueled by strong demand for freeze-drying equipment. Europe follows with a 29.5% share, with a focus on the pharmaceutical and biotechnology sectors.

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2023) | USD 2.1 Billion |

| Forecast Revenue (2033) | USD 5.1 Billion |

| CAGR (2024-2033) | 9.20% |

| Segments Covered | By Product (Bench Top Freeze Dryers , Laboratory Freeze Dryers , Mobile Freeze Dryers , General Purpose Freeze Dryers , Industrial Freeze Dryers , Others ), By Application (Food Processing , Biotechnology , Pharmaceuticals , Surgical Procedures , Others) |

| Competitive Landscape | SP Industries, Inc., GEA Group AG, Millrock Technology, Inc., Labconco Corporation , Thermo Fisher Scientific Inc., Azbil Telstar, S.L. , IMA Group, HOF Sonderanlagenbau GmbH, Cuddon Freeze Dry, Biopharma Technology, Martin Christ Gefriertrocknungsanlagen GmbH, Freezedry Specialities, Inc. |

Emerging Trends

- Pharmaceuticals and Biotechnology Demand Increase: The demand for freeze drying equipment is surging in the pharmaceutical and biotechnology sectors, driven by the need for stable preservation of sensitive biological materials, including vaccines and other biologics.

- Technological Advancements: Innovations in freeze drying technology are focusing on enhancing efficiency and automation. These include developments in sensor technology, energy efficiency, and integration with IoT for better monitoring and control processes.

- Expansion in Food Processing: The food industry increasingly adopts freeze drying to extend the shelf life and preserve the nutritional content of food, responding to consumer demand for high-quality and convenient food options.

- Geographic Expansion: Companies are strategically entering emerging markets such as Asia-Pacific and Latin America, where rapid urbanization and rising disposable incomes are boosting demand for freeze-dried products.

- Customization and Scalability: Equipment manufacturers are increasingly offering customizable solutions to cater to specific industry needs, from small-scale laboratory applications to large-scale industrial operations, allowing flexibility across various applications.

Top Use Cases

- Food Preservation: Freeze drying is extensively used in the food industry to preserve a wide variety of foods including fruits, vegetables, and ready-to-eat meals, enhancing their shelf life and retaining nutritional value.

- Pharmaceuticals: Critical in the pharmaceutical industry, freeze drying is used to stabilize medications and vaccines, ensuring they remain effective and safe over extended storage periods.

- Nutraceuticals Production: The production of dietary supplements often utilizes freeze drying to maintain the integrity and efficacy of ingredients like vitamins and herbal extracts.

- Technological Research and Development: In R&D laboratories, freeze drying helps in the lyophilization of new chemical entities or biologicals under study, essential for sample preparation and analysis.

- Document Recovery: Following water damage, freeze drying is a key technique used in restoring valuable documents and books, preventing decay and mold growth.

Major Challenges

- High Energy Consumption: Freeze drying is an energy-intensive process, leading to high operational costs and environmental concerns.

- Cost of Equipment: The high initial cost for setting up freeze drying systems can be a barrier for small to medium enterprises and startups.

- Complexity in Maintenance: The sophisticated nature of freeze drying equipment requires regular maintenance and skilled operation, adding to ongoing costs.

- Compliance with Regulations: Especially in pharmaceutical applications, complying with stringent regulatory standards worldwide can be challenging and resource-intensive.

- Technological Adaptation: Keeping up with rapid technological advancements and integrating new features into existing systems can be difficult for manufacturers.

Top Opportunities

- Customized Solutions: There is growing demand for tailored freeze drying systems that meet specific industry needs, offering significant opportunities for manufacturers to expand their product lines.

- Renewable Energy Integration: Incorporating renewable energy sources into freeze drying operations could reduce operational costs and attract eco-conscious customers.

- Emerging Markets: Expanding into rapidly developing regions such as Southeast Asia and Africa, where there is increasing demand for preserved food and pharmaceuticals, presents a significant growth opportunity.

- Automation and IoT: Advancing automation and IoT integration in freeze drying systems can improve efficiency and control, appealing to tech-savvy industries and modernizing production lines.

- After-Sales Services and Maintenance: Offering comprehensive service agreements and maintenance can help differentiate companies in a competitive market, ensuring long-term customer loyalty and steady revenue streams.

Key Player Analysis

- SP Industries, Inc.: SP Industries is recognized for its contributions to the freeze-drying sector, focusing on a range of equipment tailored for pharmaceutical, biotechnology, and industrial applications. The company’s approach to integrating advanced freeze-drying technology highlights its role in enhancing productivity and efficiency within these industries.

- GEA Group AG: This company is a major player in the market, known for its engineering excellence and comprehensive solutions across various sectors including pharmaceuticals and food processing. GEA Group AG is driving innovation in the freeze-drying market, particularly through its development of more efficient and flexible production systems, such as the use of single-use technologies which enhance manufacturing agility and reduce cross-contamination risks.

- Millrock Technology, Inc.: Specializing in the design and manufacturing of freeze-drying equipment, Millrock Technology offers robust solutions tailored to the needs of the pharmaceutical and biotech industries. The company focuses on providing equipment that supports the precise requirements of these sectors, contributing to its strong market presence.

- Labconco Corporation: Labconco offers a broad range of laboratory equipment, including freeze dryers designed for efficiency and reliability. Their products cater to both the scientific community and industrial applications, emphasizing innovation and user-friendly designs to facilitate complex drying processes.

- Thermo Fisher Scientific Inc.: As a global leader in serving science, Thermo Fisher Scientific provides a wide array of equipment and services, including freeze-drying technologies. Their offerings are designed to support the rigorous demands of pharmaceutical and biotechnological applications, ensuring high-quality results and process reliability.

Regional Analysis

North America Leads the Freeze Drying Equipment Market with the Largest Market Share of 37.1%

In 2023, the North American region continues to dominate the freeze drying equipment market, holding a substantial share of 37.1%. This region has been pivotal in the advancement and deployment of freeze drying technologies, primarily driven by the robust pharmaceutical and biotechnological sectors that heavily utilize these systems for drug formulation and biopreservation. With a market valuation of USD 0.8 billion, North America is not only the largest market in terms of revenue but also a leader in technological innovations and product developments.

The U.S. and Canada are at the forefront, adopting these technologies to enhance the longevity and efficacy of sensitive products. The strong presence of major market players in the region and their continual investments in R&D activities contribute significantly to the regional market growth. The extensive application of freeze drying equipment in food processing and pharmaceuticals in North America further underscores its leading position in the global market landscape.

Recent Developments

- In 2024, GEA enhanced their pharmaceutical freeze-drying systems, showcasing their innovations at ACHEMA in Frankfurt/Main. Their upgrades aim to improve sustainability by optimizing production processes and reducing both energy use and environmental impacts.

- In 2024, LyoWave Inc. began commercializing a new microwave heating technology for lyophilization, originally developed at Purdue University. This technology offers faster processing, lower costs, and increased product throughput compared to traditional methods.

- In 2023, Gold Coast’s Plant Doctor entered the freeze-drying market with AgTech Freeze Drying. This new venture focuses on creating freeze-dried powdered products, broadening their manufacturing offerings.

- In 2023, , GSK committed €250 million to construct a new vaccine freeze-drying facility in Wavre, Belgium. Slated to be operational by 2027, this unit will bolster vaccine production, including those for shingles and respiratory syncytial virus, at the world’s largest vaccine production site.

Conclusion

The freeze drying equipment market is poised for substantial growth in the coming decade, driven by increased demand across several key sectors. As consumers and industries alike seek longer-lasting perishable products, this technology is critical for extending the shelf life and maintaining the quality of food and pharmaceuticals. Innovations in automation and energy efficiency are expected to propel the market forward, making these systems more accessible and cost-effective. Additionally, the expansion into emerging markets presents significant opportunities for growth, as these regions experience rising incomes and urbanization. Overall, the evolving needs of both established and developing markets are shaping a dynamic future for the freeze drying equipment industry.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)