Table of Contents

Introduction

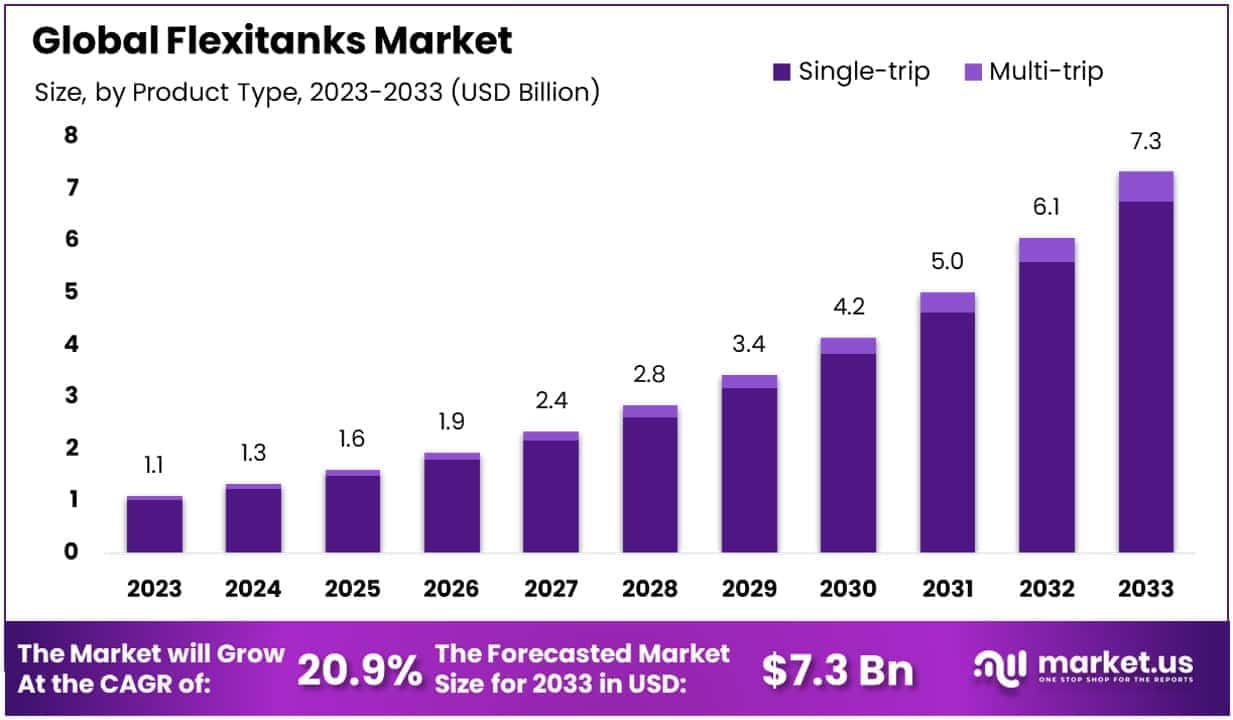

The Global Flexitanks Market is projected to grow significantly, reaching an estimated value of USD 7.3 billion by 2033, up from USD 1.1 billion in 2023. This robust growth reflects a compound annual growth rate (CAGR) of 20.9% during the forecast period from 2024 to 2033.

Flexitanks are specialized flexible containers designed to store and transport bulk liquids. These containers are typically made from multiple layers of polyethylene and an outer protective layer of woven polypropylene, offering a cost-effective, lightweight, and efficient solution for liquid logistics. With capacities ranging from 16,000 to 24,000 liters, flexitanks are primarily used to transport non-hazardous liquids such as edible oils, beverages, chemicals, and industrial liquids.

Their single-use design eliminates the risk of contamination, ensuring product integrity, and their ability to fit inside standard 20-foot containers makes them highly versatile for global trade.

The Flexitanks market refers to the global industry surrounding the production, distribution, and application of flexitank solutions across various sectors such as food & beverage, chemicals, pharmaceuticals, and industrial manufacturing. The market encompasses not only the flexitanks themselves but also ancillary services such as installation, transportation, and technical support.

As global trade in bulk liquids continues to expand, flexitanks have emerged as a key logistics solution, replacing traditional methods such as drums, intermediate bulk containers (IBCs), and ISO tanks due to their cost-efficiency and convenience.

The growth of the flexitanks market is primarily driven by the increasing demand for cost-effective, safe, and environmentally friendly liquid transportation solutions. The rapid globalization of trade in edible oils, wines, juices, and industrial chemicals has created a robust need for efficient bulk liquid logistics, where flexitanks offer significant cost advantages over traditional shipping methods.

Additionally, the growing adoption of single-use packaging solutions and the rising awareness of contamination-free transport solutions further contribute to market growth. Technological advancements in flexitank materials, such as multilayered designs that enhance strength and reduce spillage risks, are also supporting market expansion.

The demand for flexitanks is being fueled by industries that rely on large-scale transportation of liquid commodities. The food & beverage sector remains a dominant consumer due to the increasing global consumption of edible oils, juices, and wines. Similarly, the chemical industry is adopting flexitanks for transporting non-hazardous chemicals due to their efficiency and lower costs compared to ISO tanks and drums. Furthermore, the pharmaceutical sector has started utilizing flexitanks for bulk transport of non-sensitive liquid formulations, thanks to their single-use design that ensures sterility and reduces contamination risks.

The flexitanks market presents significant growth opportunities, particularly in emerging economies where liquid trade volumes are rising. Regions such as Asia-Pacific and Latin America are seeing rapid industrialization and expanding trade networks, driving the need for efficient liquid logistics solutions. Additionally, the push for sustainable packaging and transport solutions is creating opportunities for manufacturers to develop eco-friendly and recyclable flexitank designs.

Furthermore, advancements in customization, allowing flexitanks to cater to specific industry requirements (e.g., temperature control for beverages or reinforced layers for industrial liquids), open doors for differentiation and premium pricing strategies. The rise of e-commerce in the B2B sector also offers new avenues for flexitank providers to reach a broader customer base.

Key Takeaways

- The global flexitanks market is set to grow from USD 1.1 billion in 2023 to USD 7.3 billion by 2033, with a strong CAGR of 20.9% (2024–2033).

- Single-trip flexitanks dominate with a 92.3% share, driven by demand for disposable packaging solutions.

- Foodstuffs lead with 29.4% of the market, highlighting their importance in transporting perishable goods.

- Asia-Pacific leads with 46.3% market share, while North America holds 22.7% with steady growth.

Surface Roughness Measurement (SRM) Statistics

High Capacity for Liquid Transport

- Flexitanks can hold up to 24,000 liters, equivalent to 6,500 gallons.

- A single flexitank can store the equivalent of 30,000 wine bottles.

Increased Efficiency in Container Utilization

- Flexitanks allow 44% more liquid per container compared to drums.

- They carry 15% more payload than IBC totes and 50% more than bottles.

Material Composition and Durability

- Made from FDA-approved polyethylene and virgin resin.

- Offers elongation properties exceeding 600%, ensuring durability under stress.

Reduced Loading and Unloading Time

- Loading and unloading times are up to 90% faster than drums or totes.

- No forklifts are needed, simplifying the process.

Cost Savings on Freight

- Flexitanks enable reduced transportation costs by maximizing payloads.

- Large capacities reduce the need for multiple containers.

Variety of Models and Sizes

- Available capacities range from 10,000 liters to 24,000 liters.

- Options include 16,000L, 18,000L, 20,000L, 22,000L, and 24,000L sizes.

Advanced Flexitank Options

- The SIA Trinity Tank (40ft model) can hold up to 27,000 liters.

- Compatible with both standard and refrigerated containers.

Versatile Applications

- Used globally for transporting non-hazardous liquids, including food and industrial materials.

- Offers flexibility for transporting varied liquid types in the same shipment (e.g., red and white wine).

Alternative Storage Solutions

- Static storage tanks made from thermoplastic polyurethane can store up to 100,000 liters.

Environmental and Space Efficiency

- Flexible design improves container space utilization by up to 30%.

- Allows transport of large liquid volumes in fewer containers.

Enhanced Payload for Larger Containers

- The 40ft flexitank can handle payloads of up to 27 metric tonnes.

- Especially useful amid a global shortage of 20ft containers.

Streamlined Logistics

- Reduced handling requirements lower operational complexity.

- Ideal for industries requiring efficient liquid transport.

Emerging Trends

- Rising Adoption in Bulk Liquid Transport: Flexitanks are increasingly being used for transporting non-hazardous bulk liquids such as food-grade oils, wine, juices, and chemicals. With their ability to hold up to 24,000 liters per container, they offer a higher payload capacity compared to traditional drums or Intermediate Bulk Containers (IBCs), resulting in reduced freight costs and greater efficiency.

- Sustainability and Eco-Friendliness: The shift towards more sustainable transportation solutions has led to the growing popularity of flexitanks. Made from recyclable materials, they significantly reduce packaging waste. Additionally, their single-use design eliminates the need for cleaning, reducing water consumption and energy use, making them attractive for environmentally conscious businesses.

- Increasing Usage in the Food and Beverage Industry: Flexitanks have become essential in the global supply chain for liquid food products such as edible oils, syrups, and beverages. The food and beverage sector accounts for a substantial portion of flexitank usage, as these containers meet stringent hygiene and safety standards, ensuring product quality during transport.

- Technological Innovations in Flexitank Materials: Advancements in flexitank materials, such as multi-layer polyethylene and high-strength polypropylene, are improving durability, puncture resistance, and compatibility with a wider range of liquids. These innovations have enhanced their application in industries requiring specialized handling, such as the pharmaceutical and chemical sectors.

- Expanding Global Trade and Export Markets: With increasing international trade, particularly in agricultural commodities, chemicals, and industrial liquids, flexitanks are becoming a preferred choice for exporters. Their cost-effectiveness and efficiency align with the demands of global trade routes, supporting the growth of emerging economies in Asia-Pacific, South America, and Africa.

Top Use Cases

- Food-Grade Liquid Transportation: Flexitanks are widely used for transporting liquid food products, such as edible oils, juices, and syrups. For example, a single flexitank can carry up to 24,000 liters of cooking oil, eliminating the need for multiple drums and reducing overall transportation costs.

- Wine and Beverage Shipping: The beverage industry uses flexitanks for bulk transportation of wines, beer, and other non-carbonated liquids. This method minimizes packaging waste and protects the product from contamination, ensuring quality upon delivery, especially for long-distance exports.

- Non-Hazardous Chemicals: Industries rely on flexitanks to transport non-hazardous chemicals, such as liquid fertilizers, lubricants, and detergents. These tanks reduce spillage risks while maximizing cargo capacity, with each shipment accommodating 30% more liquid compared to IBCs or barrels.

- Pharmaceutical Ingredients: Flexitanks are gaining traction for transporting liquid pharmaceutical ingredients, such as glycerin and certain liquid excipients. The containers’ aseptic and single-use design ensures sterility, meeting the stringent safety requirements of the pharmaceutical industry.

- Cosmetics and Personal Care Liquids: The cosmetics industry utilizes flexitanks for transporting liquid raw materials, such as essential oils, fragrances, and liquid soaps. By offering cost savings and improved logistics, flexitanks help meet growing global demand for cosmetics products.

Major Challenges

- Risk of Contamination: Flexitanks are single-use containers, but improper handling or material defects could lead to product contamination. This is a significant concern in industries like food and pharmaceuticals, where strict hygiene standards are critical.

- Compatibility Limitations: Flexitanks are not suitable for transporting hazardous liquids or highly reactive chemicals. This limitation restricts their application scope and can be a drawback for businesses in the chemical and petroleum industries.

- Leakage and Puncture Risks: Despite advancements in materials, flexitanks remain vulnerable to punctures during handling or transit. Even a minor tear can result in the loss of an entire shipment, as these tanks typically carry up to 24,000 liters of liquid.

- Regulatory Compliance: The transport of liquids across international borders requires adherence to specific regulations. Variability in local regulations, particularly concerning food-grade liquids and pharmaceuticals, can complicate the adoption of flexitanks in some regions.

- Dependence on Infrastructure: Flexitank performance relies on proper loading and unloading infrastructure, such as forklifts and cranes. Regions with inadequate logistics capabilities may face challenges in fully utilizing flexitank benefits, impacting their adoption in emerging markets.

Top Opportunities

- Increasing Demand in Emerging Markets: Countries in Asia, Africa, and South America are witnessing rapid industrialization and export growth. The cost advantages of flexitanks make them ideal for transporting agricultural products, industrial liquids, and chemicals, presenting significant growth potential in these regions.

- Expansion in E-Commerce Supply Chains: With the rise of global e-commerce, the need for efficient and scalable bulk liquid transportation is increasing. Flexitanks can play a key role in improving last-mile delivery for liquid products like oils, juices, and personal care items.

- Focus on Sustainability Goals: Governments and corporations are increasingly emphasizing sustainability in logistics. Flexitanks, with their recyclable materials and waste reduction features, align with these goals, driving adoption among environmentally conscious businesses.

- Growing Pharmaceutical and Healthcare Sectors: The global demand for pharmaceutical products, especially liquid ingredients, is rising. Flexitanks provide a sterile and cost-effective transportation solution, making them a preferred choice in the healthcare supply chain.

- Development of Multi-Liquid Compatibility: The advancement of flexitanks capable of transporting a broader range of liquids, including semi-viscous substances, opens up new market opportunities. Innovations in design and material can expand their applications in industries that require versatile transport solutions.

Key Player Analysis

- Qingdao BLT Packing Industrial Co., Ltd.: Qingdao BLT Packing is a leading manufacturer specializing in high-quality flexitanks and liquid bulk solutions. The company has a production capacity of over 200,000 flexitanks annually, positioning it as a key player in global markets. Its focus on sustainable materials and advanced manufacturing techniques has contributed to its success. Qingdao BLT also emphasizes stringent quality assurance standards, making it a preferred partner for industries such as food, beverages, and chemicals.

- Braid Logistics UK Ltd.: Braid Logistics is a renowned logistics and bulk liquid transport company that offers a comprehensive range of flexitank solutions. With operations spanning over 50 countries, the company ensures seamless global supply chain support. It has invested heavily in research and development to create innovative flexitank designs that reduce environmental impact while enhancing durability. Braid Logistics collaborates closely with clients in the agriculture, chemical, and pharmaceutical sectors to meet specific needs.

- Bulk Liquid Solutions Pvt. Ltd.: Bulk Liquid Solutions is a key player with a strong presence in the Asia-Pacific region. The company produces approximately 150,000 flexitanks per year and has built a reputation for providing customizable liquid transport solutions. It is particularly active in serving industries such as edible oils, wines, and non-hazardous chemicals. The company’s strategic focus on competitive pricing and reliable customer support has driven its market share growth.

- Environmental Packaging Technologies, Inc.: Environmental Packaging Technologies (EPT) is a global leader specializing in innovative liquid packaging solutions. The company has shipped more than 1.5 million flexitanks worldwide, showcasing its robust operational capacity and strong client base. EPT is committed to sustainability, offering flexitanks that are recyclable and environmentally friendly. Its expertise extends to industries such as industrial lubricants, petrochemicals, and bulk food products.

- SIA FLEXITANKS: SIA FLEXITANKS, based in Europe, has established itself as a major provider of high-performance flexitank solutions, with annual production capacity exceeding 120,000 units. The company is recognized for its rigorous testing processes and compliance with international safety standards. SIA focuses on providing efficient and tailored solutions for industries such as beverage transport, industrial chemicals, and agricultural oils. Its extensive global network ensures timely delivery and customer support.

Asia Pacific Flexitanks Market

Asia Pacific Leads the Flexitanks Market with the Largest Market Share of 46.3%

The Asia Pacific region emerged as the dominant player in the global flexitanks market, capturing a significant market share of 46.3% in 2023. This leadership position is underpinned by the region’s expanding trade activities, growing export of bulk liquids, and the increasing adoption of cost-effective and efficient transportation solutions for non-hazardous liquids. Major contributors to this growth include countries such as China, India, and Southeast Asian nations, where industrialization, agriculture, and the chemical sectors are flourishing.

For instance, Asia Pacific’s market value reached USD 0.5 million in 2023, reflecting robust demand from industries that rely heavily on flexitanks for the transportation of oils, wines, chemicals, and other liquids. The region’s well-established manufacturing base, coupled with the rising demand for sustainable packaging and logistics solutions, positions it as a key growth hub for flexitanks globally. Additionally, favorable trade policies and investments in infrastructure development have further cemented Asia Pacific’s leadership in this market.

Recent Developments

- In 2023, ASF Logistics expanded its Flexitanks unit to promote the adoption of efficient and eco-friendly shipping for non-hazardous bulk liquid cargo. Led by Jeff Plumley, the initiative leverages his extensive expertise in Flexitanks and global logistics.

- In 2023, Transolve Global enhanced its bulk liquid transport solutions by introducing larger flexitanks and ISO tanks. Known for innovation and cost efficiency, the Australian company empowers clients to optimize logistics and increase payloads per container, reinforcing its leadership in the sector.

Conclusion

The global flexitanks market is poised for significant growth in the coming years, driven by the increasing need for efficient, cost-effective, and sustainable liquid transport solutions across various industries. As global trade continues to expand, particularly in food-grade liquids, chemicals, and industrial products, flexitanks offer a versatile and reliable alternative to traditional bulk liquid transportation methods.

With advancements in material technology and growing adoption in emerging markets, flexitanks are becoming integral to modern supply chain logistics. Their ability to provide contamination-free, single-use solutions aligns well with the rising focus on hygiene, safety, and sustainability. Furthermore, expanding infrastructure development and evolving trade networks globally are expected to support widespread adoption, making flexitanks a crucial innovation in the logistics and packaging industries.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)