Table of Contents

Introduction

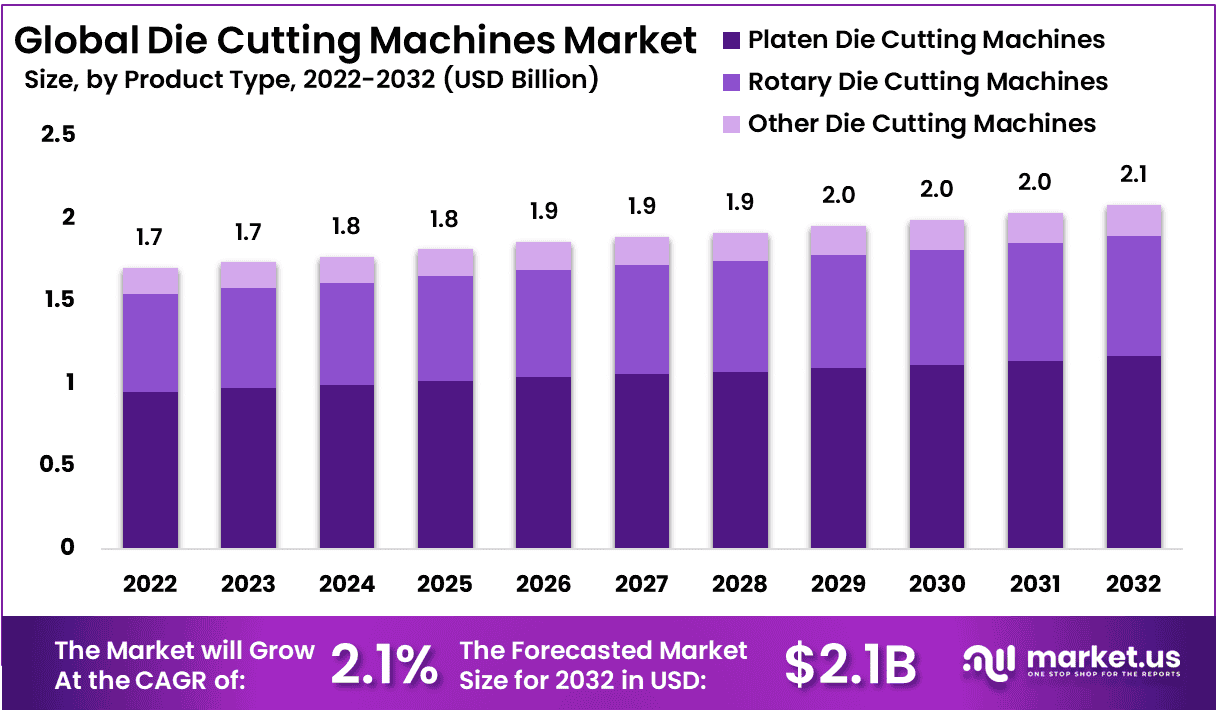

The Die Cutting Machines Market is projected to reach approximately USD 2.1 billion by 2032, up from USD 1.7 billion in 2023, reflecting a compound annual growth rate (CAGR) of 2.1% over the forecast period from 2023 to 2032.

Die cutting machines are specialized equipment used to cut, shape, or emboss materials such as paper, plastic, metal, and fabric with precision and efficiency. These machines are widely utilized across various industries, including packaging, automotive, textile, and electronics, to enhance production speed and reduce material wastage.

The die cutting machines market represents the global demand, supply, and revenue generated by manufacturers and suppliers of these machines. The market is experiencing steady growth, driven by increasing automation in manufacturing processes, rising demand for customized packaging solutions, and advancements in digital die-cutting technology.

The growth of the e-commerce sector, coupled with the rising need for sustainable and visually appealing packaging, is further fueling market expansion. Additionally, the automotive and electronics industries are witnessing significant adoption of die cutting machines for precision cutting applications, contributing to market growth.

Increasing demand from small- and medium-sized enterprises (SMEs) for cost-effective, compact, and user-friendly die cutting solutions is also influencing market dynamics. Opportunities in the market lie in the development of smart and automated die cutting machines integrated with artificial intelligence (AI) and the Internet of Things (IoT) to enhance operational efficiency.

The growing trend toward eco-friendly and recyclable packaging solutions presents an additional avenue for market expansion. However, high initial investment costs and maintenance expenses may act as restraints. Nevertheless, technological advancements, product innovation, and the increasing adoption of digital die cutting machines are expected to create significant growth prospects for the market in the coming years.

Key Takeaways

- The global Die Cutting Machines market is projected to grow from USD 1.7 billion in 2023 to USD 2.1 billion by 2032, registering a CAGR of 2.1%. Growth is driven by automation, rising precision cutting demand, and expanding applications in packaging, automotive, and electronics.

- Platen Die Cutting Machines This segment held over 56% of the market share in 2023, owing to its high precision, durability, and efficiency in large-scale production, particularly in the packaging and printing industries.

- Industrial & Manufacturing Dominance The Industrial & Manufacturing sector accounted for more than 41% of the market share in 2023, driven by increasing demand for precision-cut components in electronics, automotive, and packaging applications.

- Asia-Pacific dominated with a 31% market share, supported by the rapid growth of the manufacturing sector, particularly in packaging and electronics.

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2023) | US$ 1.7 Bn |

| Forecast Revenue (2032) | US$ 2.1 Bn |

| CAGR (2023-2032) | 2.1% |

| Segments Covered | By Product Type-Platen Die Cutting Machines, Rotary Die Cutting Machines, and Other Die Cutting Machines; By Machine Type-Manual, Semi-Automatic, and Automatic; By Application-Medical & Pharmaceutical Industry, Automobile Industry, Textile Industry, and Industrial & Manufacturing; |

| Competitive Landscape | Bobst Group SA, Heidelberger Druckmaschinen AG, Asahi-Seiki Manufacturing Co. Ltd., Koenig & Bauer AG, Sanwa Mfg. Co.Ltd., Duplo International Limited, Shandong Century Machinery Co. Ltd, IIJIMA MFG Co. Ltd, Dalian Yutong, Wenhong Machinery, Other Key Players |

Emerging Trends

- Automation Integration: The incorporation of automation technologies in die cutting machines has led to reduced labor costs and enhanced precision. Automated systems minimize manual intervention, resulting in consistent and accurate outputs.

- Digital Die Cutting: The shift towards digital die cutting methods allows for more flexibility and efficiency in design modifications, catering to the demand for customized packaging solutions.

- Sustainable Practices: There is a growing emphasis on sustainability, prompting manufacturers to adopt eco-friendly materials and processes in die cutting operations.

- Laser Die Cutting: The adoption of laser die cutting technology has increased due to its ability to provide high-speed, non-contact cutting with minimal material wastage, making it suitable for intricate designs.

- Material Versatility: Modern die cutting machines are now capable of handling a diverse range of materials, including paper, metals, and fabrics, expanding their application across various industries.

Top Use Cases

- Packaging Industry: Die cutting machines are extensively used to create boxes, cartons, and labels, essential for product packaging.

- Automotive Sector: In the automotive industry, these machines are utilized for cutting gaskets, seals, and interior components, ensuring precision and consistency.

- Textile Industry: Die cutting machines facilitate the cutting of fabrics into specific shapes and patterns, streamlining the production process in the textile sector.

- Electronics Manufacturing: They are employed to produce components like circuit boards and insulation materials, requiring high precision.

- Medical Devices: Die cutting machines are used in manufacturing medical components, such as adhesive pads and surgical instruments, where accuracy is critical.

Major Challenges

- High Initial Investment: The substantial upfront cost of acquiring advanced die cutting machines poses a financial challenge, particularly for small and medium-sized enterprises.

- Maintenance Requirements: Regular maintenance is necessary to ensure optimal performance, leading to additional operational costs and potential downtime.

- Competition from Alternative Technologies: Emerging cutting technologies, such as laser and digital cutters, offer alternatives that may be more cost-effective or efficient, impacting the traditional die cutting market.

- Skilled Labor Shortage: Operating and maintaining complex die cutting machinery requires skilled technicians, and a shortage of such personnel can hinder productivity.

- Economic Fluctuations: Economic downturns can lead to reduced consumer spending, affecting the demand for products that utilize die cutting machines in their production processes.

Top Opportunities

- Technological Advancements: Investing in automation and digital integration can enhance productivity and reduce production costs, offering a competitive edge.

- Customization Demand: The growing trend for personalized products presents opportunities for die cutting services to offer tailored solutions.

- Sustainable Packaging: The push for environmentally friendly packaging solutions increases the demand for die cutting machines capable of handling recyclable and biodegradable materials.

- Emerging Markets: Expanding into emerging markets with growing manufacturing sectors can provide new avenues for growth.

- E-commerce Growth: The rise of e-commerce boosts the need for packaging solutions, thereby increasing the demand for die cutting machines in packaging production.

Key Player Analysis

The global die cutting machines market in 2024 is characterized by the presence of well-established players focusing on technological innovation, automation, and precision engineering. Bobst Group SA and Heidelberger Druckmaschinen AG remain dominant, leveraging advanced digital solutions and automation to enhance production efficiency.

Asahi-Seiki Manufacturing Co. Ltd. and Koenig & Bauer AG emphasize high-speed, high-precision die-cutting technologies to cater to the growing packaging and labeling industry. Sanwa Mfg. Co. Ltd. and Duplo International Limited continue to expand their footprint through product customization and integration of smart manufacturing capabilities.

Shandong Century Machinery Co. Ltd., IIJIMA MFG Co. Ltd., Dalian Yutong, and Wenhong Machinery play a crucial role in offering cost-effective solutions, particularly targeting emerging markets. The competitive landscape is further shaped by regional players focusing on affordability and adaptability, reinforcing market fragmentation. Innovation in automation, digital die-cutting, and sustainability will remain key differentiators among these players

Top Key Players in the Market

- Bobst Group SA

- Heidelberger Druckmaschinen AG

- Asahi-Seiki Manufacturing Co. Ltd.

- Koenig & Bauer AG

- Sanwa Mfg. Co.Ltd.

- Duplo International Limited

- Shandong Century Machinery Co. Ltd

- IIJIMA MFG Co. Ltd

- Dalian Yutong

- Wenhong Machinery

- Other Key Players

Regional Analysis

Asia-Pacific Leads Die Cutting Machines Market with Largest 31% Market Share

Asia-Pacific dominated the die cutting machines market in 2024, accounting for the largest market share of 31%, with a market valuation of USD 0.5 billion. The region’s leadership is driven by the expanding manufacturing and packaging industries, particularly in China, India, and Japan. Rapid industrialization, increasing demand for automated cutting solutions, and the growth of the e-commerce sector have contributed to the rising adoption of die cutting machines.

China remains a key contributor, benefiting from a robust production ecosystem and technological advancements. Furthermore, government initiatives supporting industrial automation and cost-effective manufacturing processes continue to bolster market expansion. The presence of leading market players and increasing investments in precision manufacturing technologies further enhance the region’s dominance.

Recent Developments

- In 2023, S. Walter Packaging expanded its capabilities with advanced BOBST die-cutting technology. The company integrated two VISIONCUT 106 LER flatbed machines into its Milwaukee-based LPI division, enhancing efficiency in folding carton, rigid box, and specialty packaging production. This move aligns with its long-term strategy for operational growth as it approaches 120 years in business in 2024.

- In 2024, CML Micro strengthened its market position by acquiring PRFI, a UK-based specialist in RFIC and MMIC design. PRFI’s expertise spans applications in test equipment, infrastructure, and high-volume consumer wireless devices. The acquisition is expected to bolster CML Micro’s capabilities in high-frequency communication solutions.

- In 2024, Spirent Communications and Keysight Technologies reached an agreement for an all-cash acquisition of Spirent’s entire issued share capital. The deal, executed under the UK Companies Act 2006, received shareholder approval on May 22, 2024, following resolutions passed at the Court and General Meetings. The acquisition is set to enhance Keysight’s portfolio in network testing and assurance solutions.

- In 2024, Anritsu Corporation announced its decision to acquire a 32.72% stake in SmartViser SAS, a provider of automated testing solutions for mobile networks and devices. The agreement, finalized on November 28, 2024, is subject to regulatory approval and fulfillment of all necessary conditions. The acquisition supports Anritsu’s commitment to advancing mobile network testing technologies.

Conclusion

The die cutting machines market is projected to experience steady growth, driven by increasing automation in manufacturing processes, rising demand for customized packaging solutions, and advancements in digital die-cutting technology. The packaging industry, in particular, remains a significant contributor to this growth, fueled by the expansion of e-commerce and the need for innovative and sustainable packaging designs. Additionally, the automotive and electronics sectors are adopting die cutting technologies for precision manufacturing, further bolstering market expansion. However, challenges such as high initial investment costs and maintenance expenses may hinder rapid adoption, especially among small and medium-sized enterprises. Nonetheless, technological advancements and product innovations are expected to create substantial growth prospects in the coming years.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)