Table of Contents

Introduction

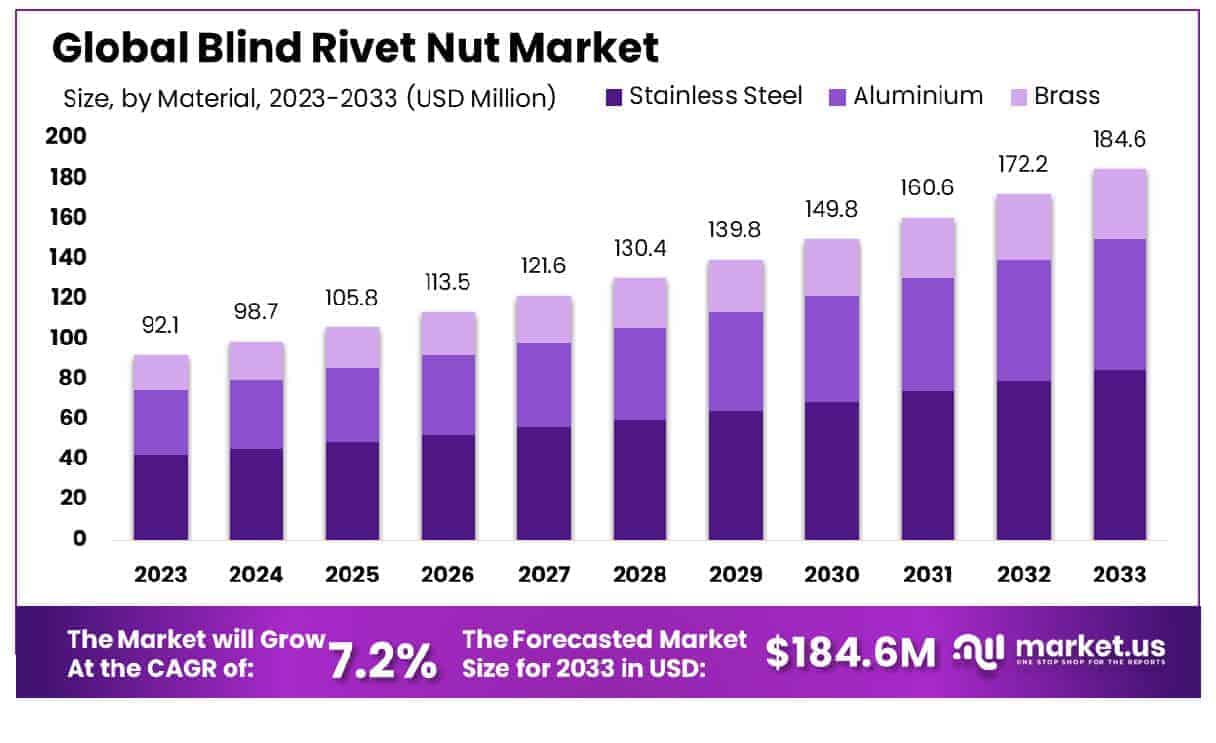

The Global Blind Rivet Nut Market is projected to reach USD 184.6 million by 2033, up from USD 92.1 million in 2023, reflecting a compound annual growth rate (CAGR) of 7.20% over the forecast period from 2024 to 2033.

The blind rivet nut, a mechanical fastener, is utilized in applications requiring a secure, threaded fastening system in materials that cannot be accessed from both sides. Often made from aluminum, steel, or brass, these fasteners are installed by inserting them into a pre-drilled hole and then expanding the body to form a strong, permanent bond with the workpiece.

The blind rivet nut market refers to the industry segment involved in the production, distribution, and application of these fasteners across diverse sectors, including automotive, aerospace, construction, and industrial manufacturing. Growth in the blind rivet nut market can be attributed to several factors, including the increasing demand for lightweight materials and cost-effective assembly processes in industries such as automotive and aerospace.

These industries rely on blind rivet nuts for efficient, reliable, and secure fastening, particularly in complex or hard-to-reach areas. Additionally, the market is witnessing a rise in automation and precision engineering, which further drives the adoption of these fasteners in production lines. The growing need for robust, high-performance materials, especially in the automotive and aerospace sectors, is anticipated to further bolster demand.

Moreover, the global trend toward sustainability and eco-friendly solutions is creating new opportunities for innovation within the market, with an increasing preference for recyclable and durable materials. As such, key opportunities for market expansion lie in technological advancements, particularly in the development of high-strength blind rivet nuts and the growing adoption of automation in assembly processes across various industrial applications.

Key Takeaways

- The global blind rivet nut market is projected to grow from USD 92.1 million in 2023 to USD 184.6 million by 2033, at a CAGR of 7.20% from 2024 to 2033.

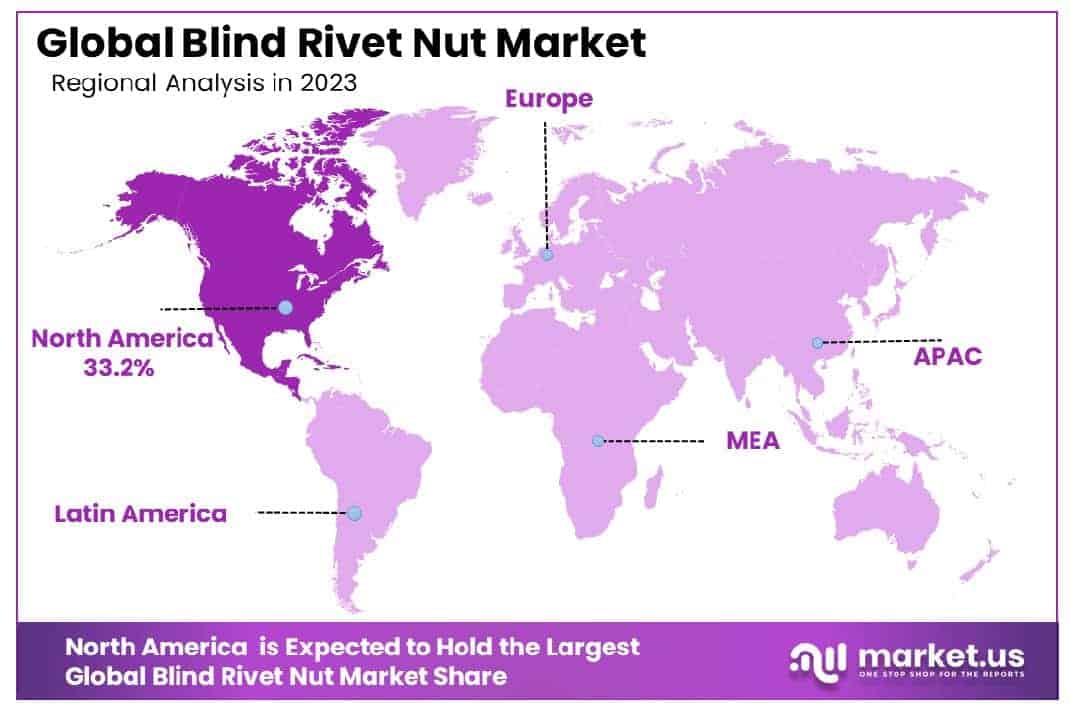

- In 2023, North America led the market with a 33.2% growth, driven by demand in automotive and manufacturing sectors.

- Stainless steel is the dominant material, holding a 52% market share due to its strength and corrosion resistance.

- Automotive applications account for 27% of the market, fueled by the need for lightweight, high-strength fasteners.

- Online channels lead distribution with a 54% share, driven by the rise of e-commerce and bulk purchasing.

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2023) | USD 92.1 Million |

| Forecast Revenue (2033) | USD 184.6 Million |

| CAGR (2024-2033) | 7.20% |

| Segments Covered | By Material(Stainless Steel, Aluminium, Brass), By Application(Automotive, Aerospace, Building & Construction, Industrial Machinery, Home Appliances, Other Applications), By Distribution Channel(Offline, Online) |

| Competitive Landscape | Acument Global Technologies Inc., STANLEY Engineered Fastening, Bulten AB, LISI Group, Hilti Corporation, Fortana Group, MISUMI Group Inc., MacLean-Fogg Company, Precision Castparts Corp., The SFS Group, Nifco Inc., Other Key Players |

Emerging Trends

- Shift Toward Lightweight Materials: There is a growing adoption of lightweight materials such as aluminum and composites, especially in the automotive and aerospace industries. This trend is driving the demand for blind rivet nuts that can maintain high performance despite material changes.

- Automation in Manufacturing: The integration of automation in production lines is improving efficiency and consistency in the production of blind rivet nuts. This is contributing to the lowering of manufacturing costs, making them more accessible to a wider range of industries.

- Growth in Electric Vehicle Production: As the electric vehicle (EV) market grows, the need for lightweight, reliable fastening solutions increases. Blind rivet nuts are being increasingly used in EV assembly, where high-strength, lightweight materials are critical.

- Increased Demand for Customization: Manufacturers are increasingly offering blind rivet nuts in customized sizes, finishes, and coatings to meet specific industry needs. This trend is being driven by the rising demand for precision and unique specifications in manufacturing.

- Sustainability Initiatives: Companies are focusing on producing environmentally friendly fasteners by using recycled materials and ensuring that the manufacturing processes have a minimal carbon footprint. This is helping the blind rivet nut market align with broader sustainability goals.

Top Use Cases

- Automotive Manufacturing: Blind rivet nuts are used extensively in automotive assembly for securing panels, seats, and other components, especially in applications requiring a strong but lightweight solution.

- Aerospace: The aerospace sector utilizes blind rivet nuts in aircraft and satellite manufacturing, particularly in situations where access to both sides of the workpiece is limited. These fasteners are vital for assembling complex structures.

- Electronics: In electronics, blind rivet nuts are used to attach circuit boards to enclosures, providing a secure and reliable connection that can withstand vibrations and other environmental stresses.

- Construction and Infrastructure: These fasteners are used in construction to secure components in place, particularly in situations where traditional fastening methods may not be viable due to space constraints.

- Consumer Goods: Blind rivet nuts are used in consumer electronics and appliances to assemble casings and other components, offering both functionality and aesthetic appeal.

Major Challenges

- Material Compatibility: Blind rivet nuts may not be compatible with all materials, particularly when extreme conditions or high-temperature environments are involved. This can limit their application in some sectors.

- Installation Complexity: While they offer ease of installation in certain cases, the need for specialized tools and trained personnel to install them correctly can pose a challenge, particularly in high-volume manufacturing.

- Limited Load-Bearing Capacity: Despite being strong, the load-bearing capacity of blind rivet nuts may not be sufficient for all applications, especially in industries that require extremely high-strength fasteners.

- Environmental Resistance: In certain conditions, such as exposure to corrosive environments, the performance of blind rivet nuts can degrade unless they are coated or treated with protective finishes, adding to the cost and complexity.

- Cost Considerations: While blind rivet nuts are generally cost-effective, their price can vary significantly based on material, coating, and customization requirements, which may be a barrier for some businesses, particularly in cost-sensitive industries.

Top Opportunities

- Growth in Renewable Energy Sector: The renewable energy industry, particularly in the construction of wind turbines and solar panels, presents an opportunity for the adoption of blind rivet nuts due to their ability to provide reliable, secure connections in lightweight structures.

- Technological Advancements in Manufacturing: Innovations in manufacturing techniques, such as additive manufacturing (3D printing) and more precise machine tooling, provide opportunities to improve the design and functionality of blind rivet nuts.

- Expanding Use in EV Infrastructure: As the electric vehicle infrastructure expands, there is a growing demand for high-performance, lightweight, and durable fasteners in charging stations, batteries, and EV components.

- Customization Services: With increasing demand for specific applications, offering customization options for blind rivet nuts, including size variations, finishes, and material types, can open new markets and attract diverse industries.

- Growing Demand in Emerging Economies: As industrialization accelerates in developing nations, the demand for reliable and efficient fasteners like blind rivet nuts is increasing, presenting new growth opportunities in regions such as Asia Pacific and Latin America.

Key Player Analysis

In the Global Blind Rivet Nut Market, several key players are positioned to influence market dynamics in 2024. Acument Global Technologies Inc. and STANLEY Engineered Fastening stand out due to their extensive product portfolios and established presence in automotive, aerospace, and industrial sectors.

Bulten AB and LISI Group also hold a significant market share, leveraging their strong capabilities in producing fastening solutions tailored to meet the demands of large-scale manufacturing industries. Hilti Corporation and Fortana Group have a robust market presence, particularly in construction and infrastructure projects, while MISUMI Group Inc. and MacLean-Fogg Company continue to strengthen their position through strategic product innovations and a global distribution network.

Precision Castparts Corp. and The SFS Group focus on high-precision manufacturing processes, catering to industries with stringent quality requirements. Nifco Inc. is also notable for its specialized fasteners for the automotive and consumer goods sectors. These companies, alongside other regional players, are set to drive market growth through technological advancements and expansion in emerging markets.

Top Market Key Players

- Acument Global Technologies Inc.

- STANLEY Engineered Fastening

- Bulten AB

- LISI Group

- Hilti Corporation

- Fortana Group

- MISUMI Group Inc.

- MacLean-Fogg Company

- Precision Castparts Corp.

- The SFS Group

- Nifco Inc.

- Other Key Players

Regional Analysis

The North American blind rivet nut market is projected to account for 33.2% of the global market share by 2024, solidifying its position as the dominant region. The region’s growth is primarily driven by the expanding automotive, aerospace, and manufacturing industries, which are increasingly adopting blind rivet nuts for their ease of installation and high-strength fastening capabilities. In 2023, North America held a substantial share of the blind rivet nut market, largely due to the presence of key automotive manufacturers and a robust aerospace sector in the U.S. and Canada.

The automotive sector is expected to remain a key driver of demand, with increasing production volumes and the growing trend of lightweight vehicles pushing the adoption of advanced fastening solutions. Furthermore, the region benefits from a well-established distribution network and the presence of several prominent players offering a wide range of products catering to diverse industrial applications. As the market in North America continues to evolve, technological advancements and innovations in material science, such as the development of corrosion-resistant and lightweight blind rivet nuts, will further enhance the market’s growth potential. The robust industrial ecosystem, along with favorable government regulations promoting manufacturing and automotive development, will likely continue to support North America’s dominant position in the global blind rivet nut market.

Recent Developments

- In 2024, Bossard Group enhanced its market position with the acquisition of Dejond Fastening NV, a Belgian company known for its high-quality fastening systems. The deal strengthens Bossard’s value chain, spanning production and sales, and further positions the company within the growing sector of blind rivet nuts. Dejond’s expertise and its Tubtara® brand complement Bossard’s strategic objectives, extending its capabilities in key fastening solutions.

- In 2024, PennEngineering® announced its acquisition of Sherex® Fastening Solutions, a leading provider of blind rivet nuts and related fastening technologies. Based in Buffalo, New York, Sherex has built a reputation for its technical expertise and innovative solutions. This acquisition supports PennEngineering’s commitment to expanding its global footprint and enhancing its production capabilities in the fastening industry.

- In 2024, Apex Group and Flow expanded their collaboration by launching Apex Ventures, a new initiative aimed at providing specialized services for venture capital managers. Apex Ventures leverages Flow’s advanced technology to offer a seamless, integrated platform for managing the entire lifecycle of a VC fund. This partnership aims to simplify operations and enhance the investor experience by combining innovative software with Apex Group’s extensive industry knowledge.

Conclusion

The global blind rivet nut market is poised for steady growth driven by the increasing demand across industries such as automotive, aerospace, construction, and electronics. As manufacturing processes evolve and automation becomes more widespread, the adoption of blind rivet nuts is expected to rise, particularly due to their efficiency, ease of installation, and ability to support lightweight, high-performance materials. Furthermore, the ongoing focus on sustainability and customization is creating new opportunities for market expansion, while challenges related to material compatibility and installation complexity remain areas for improvement. With key players continuing to innovate and emerging economies showing a rising demand for efficient fastening solutions, the market is well-positioned for long-term growth and further diversification in its applications.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)