Table of Contents

Introduction

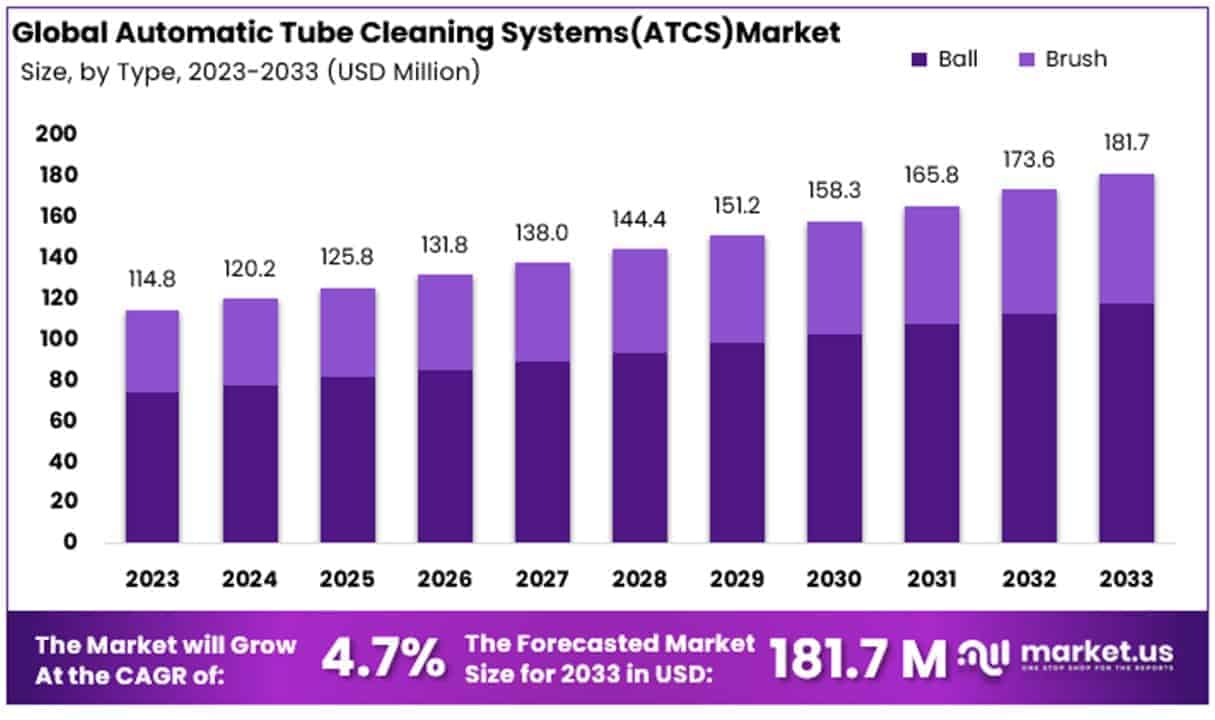

The Global Automatic Tube Cleaning Systems (ATCS) Market is projected to reach approximately USD 181.7 million by 2033, increasing from USD 114.8 million in 2023. This growth represents a compound annual growth rate (CAGR) of 4.7% over the forecast period from 2024 to 2033.

The Automatic Tube Cleaning Systems (ATCS) market is witnessing substantial growth due to the increasing need for efficient heat exchanger maintenance in industries such as power generation, oil & gas, HVAC, and manufacturing. ATCS refers to a technology that continuously cleans the internal surfaces of tubes in heat exchangers, condensers, and chillers, preventing fouling, scaling, and efficiency loss. These systems improve operational efficiency, reduce energy consumption, and extend equipment lifespan, making them a crucial component in industrial and commercial applications.

The market is driven by several key growth factors, including rising energy costs, stringent environmental regulations, and the increasing adoption of automation in industrial processes. Additionally, the growing demand for energy-efficient solutions and the need to reduce carbon emissions are prompting industries to invest in ATCS for optimal performance.

The demand for ATCS is further amplified by expanding industrialization and urbanization, particularly in emerging economies, where infrastructure development and HVAC installations are increasing. Moreover, the emphasis on sustainability and green building initiatives is creating lucrative opportunities for market players, as ATCS plays a vital role in enhancing the efficiency of cooling and heating systems. Advancements in ATCS technology, such as IoT-enabled monitoring and automated control features, are further propelling market expansion.

However, the high initial cost of installation and the requirement for periodic maintenance may pose challenges to widespread adoption. Nevertheless, the market is expected to grow steadily, driven by increasing awareness of energy savings and the long-term cost benefits associated with automatic tube cleaning systems.

Key Takeaways

- Automatic Tube Cleaning Systems (ATCS) Market Valued at USD 114.8 million in 2023, the ATCS market is projected to grow at a CAGR of 4.7%, reaching USD 181.7 million by 2033.

- The Automatic Ball Tube Cleaning System holds the largest share 65%, favored for its efficiency and low maintenance, particularly in power generation.

- The hospitality sector leads with 37%, driven by the demand for efficient HVAC systems in hotels and resorts.

- ATCS is widely used in power generation, commercial spaces, oil & gas, and other industries to enhance performance and energy efficiency.

- APAC dominates the market 32%, driven by rapid industrialization and increasing demand for energy efficiency solutions.

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2023) | USD 114.8 million |

| Forecast Revenue (2033) | USD 181.7 million |

| CAGR (2024-2033) | 4.7% |

| Segments Covered | By Type (Automatic Ball Tube Cleaning System, Automatic Brush Tube Cleaning System), By Application (Power Generation, Commercial Spaces, Oil & Gas, Hospitality, Other Applications) |

| Competitive Landscape | Taprogge GmbH, Ovivo, WesTech, BEAUDREY, Balltech Energy Ltd., Nijhuis, Conco Services LLC, Innovas Technologies, LLC, WSA Engineered Systems, Inc., Hydroball Technics Holdings Pte Ltd., |

Emerging Trends

- Integration of IoT and Smart Technologies: The incorporation of Internet of Things (IoT) sensors and smart monitoring systems into ATCS allows for real-time data analysis and predictive maintenance, enhancing operational efficiency.

- Emphasis on Energy Efficiency: Industries are increasingly adopting ATCS to improve heat exchanger efficiency, leading to reduced energy consumption and operational costs.

- Adoption in HVAC Systems: The use of ATCS in Heating, Ventilation, and Air Conditioning (HVAC) systems is on the rise to maintain optimal performance and indoor air quality.

- Environmental Compliance: Stricter environmental regulations are encouraging industries to implement ATCS to minimize waste and improve sustainability.

- Technological Advancements: Continuous innovations in ATCS design and functionality are leading to more efficient and cost-effective solutions.

Top Use Cases

- Power Generation: ATCS are utilized in power plants to maintain condenser efficiency, thereby ensuring consistent electricity production.

- Oil and Gas Industry: In refineries, ATCS help in preventing fouling in heat exchangers, which is crucial for maintaining process efficiency.

- Commercial Buildings: Large facilities use ATCS in their HVAC systems to ensure efficient cooling and heating operations.

- Marine Industry: Ships employ ATCS to prevent biofouling in their cooling systems, which is essential for maintaining engine performance.

- Food and Beverage Industry: ATCS are applied to maintain the efficiency of heat exchangers used in various processing operations, ensuring product quality.

Major Challenges

- High Initial Investment: The cost of installing ATCS can be substantial, which may deter some organizations from adopting the technology.

- Maintenance Requirements: While ATCS reduce manual cleaning, they still require regular maintenance to function effectively.

- Compatibility Issues: Integrating ATCS with existing systems can be challenging, especially in older facilities.

- Operational Downtime: Improper installation or malfunctioning of ATCS can lead to unexpected downtimes, affecting productivity.

- Limited Awareness: Some industries may lack awareness of the benefits of ATCS, leading to slower adoption rates.

Top Opportunities

- Expansion in Emerging Markets: Rapid industrialization in emerging economies presents significant opportunities for ATCS adoption.

- Retrofit Projects: Upgrading existing facilities with ATCS offers a substantial market opportunity, particularly in industries seeking energy efficiency improvements.

- Development of Cost-Effective Solutions: Innovating more affordable ATCS can attract small and medium-sized enterprises.

- Aftermarket Services: Providing maintenance and support services for ATCS can be a lucrative business avenue.

- Collaborations with OEMs: Partnering with Original Equipment Manufacturers to integrate ATCS into new equipment designs can drive market growth.

Key Player Analysis

The Global Automatic Tube Cleaning Systems (ATCS) Market in 2024 is characterized by the presence of several key players that drive innovation, efficiency, and market expansion. Taprogge GmbH, a pioneer in ATCS, continues to lead with its advanced filtration and water treatment solutions, ensuring high thermal efficiency. Ovivo and WesTech leverage their strong expertise in water and wastewater treatment to enhance ATCS applications in industrial and municipal sectors.

BEAUDREY is recognized for its specialized screening and condenser cleaning technologies, contributing to improved plant performance. Balltech Energy Ltd. and Nijhuis focus on energy-efficient ATCS solutions, addressing sustainability concerns. Conco Services LLC and Innovas Technologies, LLC emphasize performance optimization through automated maintenance systems. WSA Engineered Systems, Inc. offers customized solutions, catering to diverse industry needs. Hydroball Technics Holdings Pte Ltd. remains a significant player with its innovative hydro-mechanical cleaning systems. These companies collectively shape the competitive landscape, fostering technological advancements and market growth.

Market Key Players

- Taprogge GmbH

- Ovivo

- WesTech

- BEAUDREY

- Balltech Energy Ltd.

- Nijhuis

- Conco Services LLC

- Innovas Technologies, LLC

- WSA Engineered Systems, Inc.

- Hydroball Technics Holdings Pte Ltd.

Regional Analysis

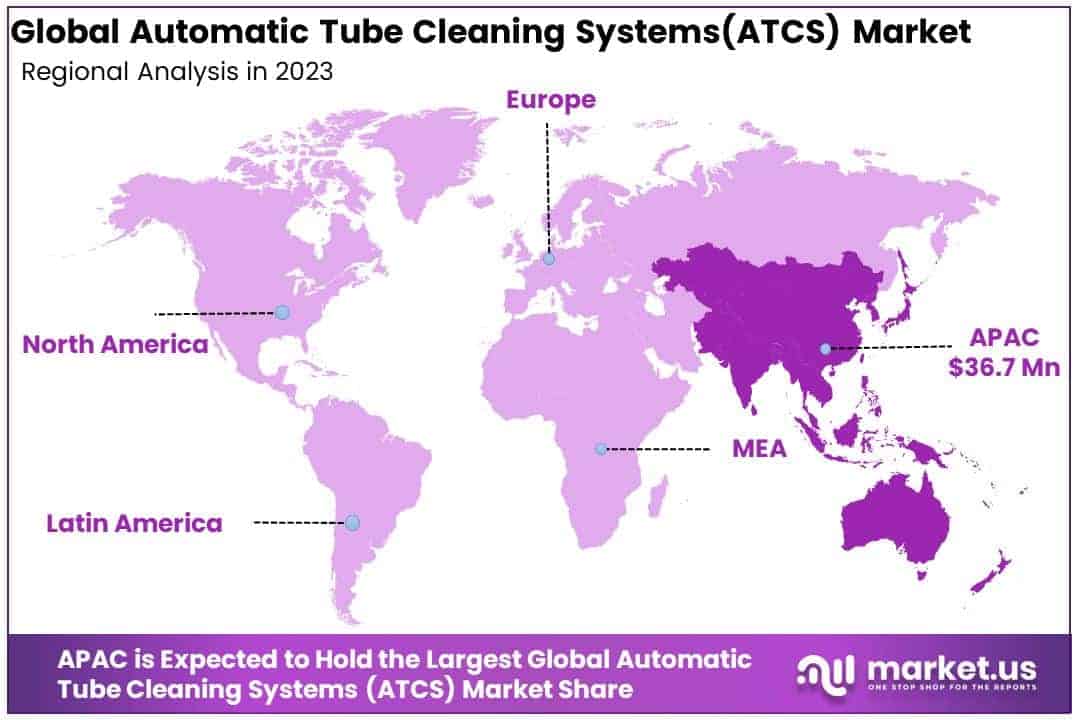

Asia Pacific Leads the Automatic Tube Cleaning Systems Market with Largest Market Share of 32% in 2024

The Asia Pacific region dominates the Automatic Tube Cleaning Systems (ATCS) Market, accounting for a 32% market share in 2024, with a market value of approximately USD 36.7 million. The region’s growth is driven by rapid industrialization, increasing adoption of energy-efficient HVAC systems, and significant investments in power generation and desalination plants.

Countries such as China, India, Japan, and South Korea are major contributors to market expansion due to the rising demand for continuous and cost-effective heat exchanger maintenance solutions. Moreover, government regulations promoting energy conservation and operational efficiency further accelerate market adoption.

The increasing need for sustainable and automated maintenance solutions in industries such as power generation, oil & gas, commercial buildings, and hospitality continues to strengthen market demand. Asia Pacific’s leadership in the ATCS market is expected to persist, supported by growing infrastructure development and technological advancements in industrial automation.

Recent Developments

- In 2024, Innovas Technologies secured two international contracts to provide its automatic air-conditioning tube cleaning system to major energy facilities in Qatar and the United Arab Emirates. Chuck Dirks, the 59-year-old president of Innovas Technologies, shared with The Gazette that both projects had their origins in 2016, following discussions with key leaders in the United Arab Emirates, Saudi Arabia, and Qatar to explore business opportunities in the energy, oil, and gas industries.

- In 2024, Thermax established a new wholly-owned subsidiary, Thermax Vebro Polymers India (TVPIPL), which officially came into existence on July 18, 2024, upon receiving a certificate of incorporation from the Ministry of Corporate Affairs (MCA). TVPIPL now functions as a step-down subsidiary of Thermax, strengthening the company’s presence in the integrated solutions sector. The subsidiary has an authorized share capital of Rs 20 crore, comprising 2 crore equity shares valued at Rs 10 each, with a paid-up capital of Rs 8,10,73,000.

Conclusion

The Automatic Tube Cleaning Systems (ATCS) market is set for steady growth, driven by the need for energy efficiency and reliable heat exchanger maintenance across industries like power generation, oil & gas, and HVAC. These systems help prevent fouling and scaling, reducing energy losses and operational costs. Technological advancements, such as IoT integration, enhance their efficiency and appeal. While high installation costs and maintenance requirements pose challenges, the long-term benefits of improved performance, sustainability, and regulatory compliance make ATCS a valuable investment for industries seeking optimized operations.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)