Table of Contents

Overview

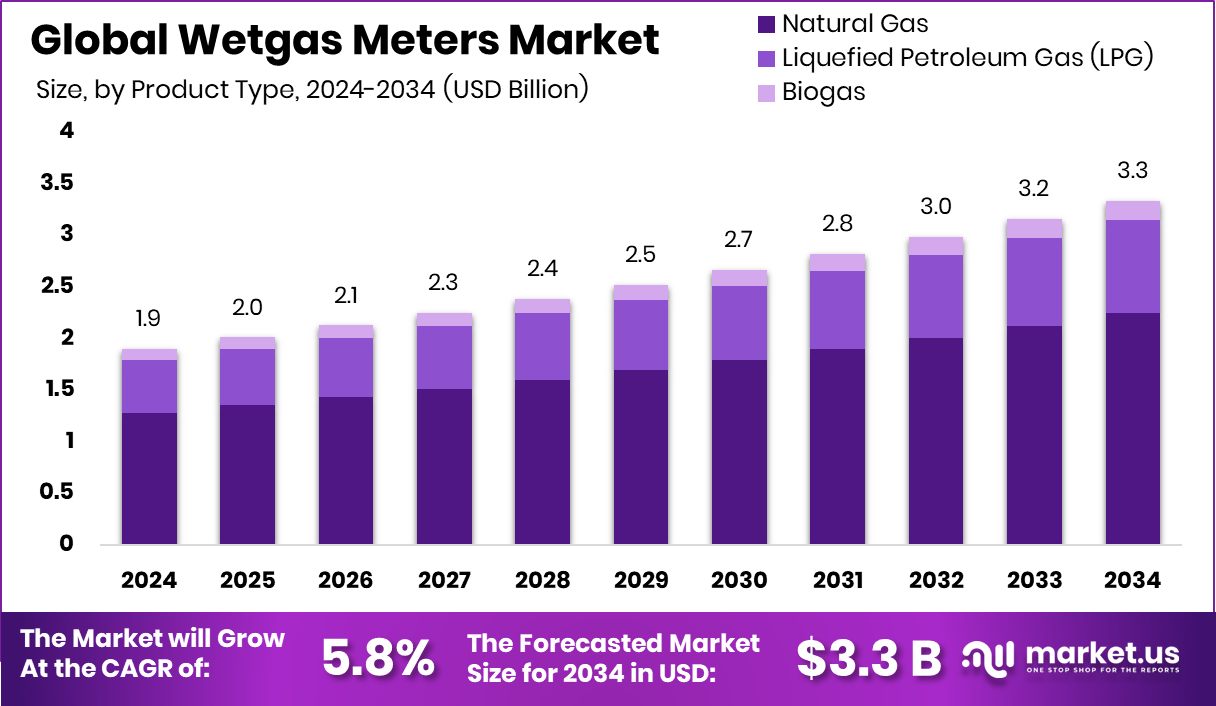

New York, NY – August 07, 2025 – The Global Wetgas Meters Market is projected to grow from USD 1.9 billion in 2024 to USD 3.3 billion by 2034, achieving a CAGR of 5.8% from 2025 to 2034. North America led with a 47.2% market share, driven by robust oilfield operations.

Wetgas meters are advanced flow measurement devices designed to accurately gauge gas flow in pipelines containing small amounts of liquid, such as water or condensate. Unlike standard dry gas meters, they maintain precision in multiphase conditions, making them vital for oil and gas production where extracted gas often contains liquid.

The wetgas meters market encompasses the global production, distribution, and use of these devices in oil and gas operations, involving upstream producers, equipment manufacturers, and service providers. Growth is fueled by the demand for precise flow measurement in challenging multiphase environments, particularly in deepwater and offshore fields.

Increased offshore and deepwater exploration, coupled with aging oil fields producing higher water content, drives the need for reliable wetgas meters. The shift toward digital oilfields further boosts the adoption of smart metering technologies. These meters enhance production efficiency and ensure regulatory compliance by minimizing measurement errors, reducing operational risks, and optimizing output in wet gas environments critical for natural gas as a transitional fuel.

Key Takeaways

- The Global Wetgas Meters Market is expected to be worth around USD 3.3 billion by 2034, up from USD 1.9 billion in 2024, and is projected to grow at a CAGR of 5.8% from 2025 to 2034.

- In the Wetgas Meters Market, natural gas applications dominate with a 67.3% share in 2024.

- Stainless steel wetgas meters held a leading 78.8% market share, favored for their durability and reliability.

- Onshore installations accounted for 79.2% of the Wetgas Meters Market due to easier accessibility and deployment.

- Industrial end-use led the Wetgas Meters Market, capturing 69.1% owing to rising energy measurement demands.

- The market in North America reached USD 0.8 billion due to rising gas demand.

➤ Curious about the content? Explore a sample copy of this report – https://market.us/report/wetgas-meters-market/request-sample/

Report Scope

| Market Value (2024) | USD 1.9 Billion |

| Forecast Revenue (2034) | USD 3.3 Billion |

| CAGR (2025-2034) | 5.8% |

| Segments Covered | By Product Type (Natural Gas, Liquefied Petroleum Gas (LPG), Biogas), By Type (Stainless Steel Wetgas Meter, Brass Wetgas Meter), By Application (Onshore, Offshore), By End-Use (Industrial (Oil and Gas, Chemical, Others), Commercial, Residential) |

| Competitive Landscape | AMETEK, Apex Instruments Inc., CX Instrument, DP Diagnostics, Dr.Ing. RITTER Apparatebau GmbH and Co. KG, EMCO Controls AS, Emerson Electric Co., Expro, Fluid Components LLC, Force Technology, Haimo Technologies Group Corp., Instrumentation and Scientific Instruments Pvt. Ltd., Krohne, MaxiFlo, SEIL ENTERPRISE Co. |

➤ Directly purchase a copy of the report – https://market.us/purchase-report/?report_id=153814

Key Market Segments

By Product Type Analysis

In 2024, natural gas dominated the By Product Type segment of the Wetgas Meters Market, capturing a 67.3% share. This is driven by the widespread use of wetgas meters in natural gas fields, where extracted gas often contains liquids like water or hydrocarbons. These meters deliver precise, real-time flow measurements despite liquid presence, supporting operators in optimizing recovery and meeting regulatory standards.

The rising demand for natural gas as a cleaner transitional fuel for power generation and industrial use further boosts the need for accurate metering. With mature fields producing higher water content, wetgas meters are vital for efficient production and accurate allocation. Their compact, reliable design also suits the growing number of offshore and deepwater natural gas projects.

By Type Analysis

In 2024, stainless steel wetgas meters led the By Type segment with a 78.8% share, owing to their durability, corrosion resistance, and strength in harsh wet gas environments. These qualities make stainless steel ideal for high-pressure, high-temperature, and corrosive conditions, especially in offshore and deepwater settings.

The meters’ long lifespan and low maintenance needs drive their adoption, as downtime in these fields can lead to significant losses. Stainless steel’s compatibility with advanced sensors also supports integration with digital systems, enhancing real-time monitoring. This dominant share reflects stainless steel’s critical role in ensuring accurate, reliable flow measurement in challenging multiphase conditions.

By Application Analysis

In 2024, onshore applications held a 79.2% share of the Wetgas Meters Market, driven by the high volume of natural gas production and processing in onshore fields. Aging reservoirs and enhanced recovery techniques result in gas streams with varying liquid content, making wetgas meters essential for precise measurement and performance monitoring.

Onshore sites benefit from easier access and lower operational complexity compared to offshore, facilitating widespread meter adoption. Operators prioritize cost-effective, durable solutions, and wetgas meters meet these needs with real-time diagnostics and efficient production management. The focus on expanding domestic gas output from onshore basins further solidifies this segment’s dominance.

By End-Use Analysis

In 2024, the industrial segment led the By End-Use category with a 69.1% share, reflecting the heavy reliance on wetgas meters in gas production, processing, and distribution. Industries like energy, petrochemicals, and manufacturing require precise flow measurement to ensure efficiency and compliance with safety and emission regulations.

Wetgas meters excel in handling complex multiphase flows, reducing measurement uncertainty, and optimizing performance. Their durability, low maintenance, and adaptability to variable conditions make them ideal for industrial settings. Integration with automated systems further enhances real-time decision-making, cementing their value in driving operational efficiency.

Regional Analysis

In 2024, North America led the global Wetgas Meters Market with a 47.2% share, valued at USD 0.8 billion, driven by its robust oil and gas infrastructure, particularly in the U.S. and Canada. Mature gas fields in the region rely on wetgas meters for accurate multiphase flow measurement, supporting efficiency and regulatory compliance in both onshore and offshore operations.

Europe’s market is fueled by stringent environmental standards, encouraging advanced metering adoption in aging gas fields. Asia Pacific shows strong growth potential, with energy-producing nations upgrading systems for complex field conditions and expanding exploration in Southeast Asia and Australia. The Middle East & Africa benefits from large-scale gas projects, while Latin America sees moderate growth driven by energy infrastructure investments.

Top Use Cases

- Natural Gas Production: Wetgas meters measure gas flow with small liquid content in natural gas fields. They ensure accurate volume tracking, helping operators optimize production and meet regulatory standards. Their ability to handle wet gas conditions makes them essential for efficient resource allocation in both onshore and offshore fields.

- Offshore Oil and Gas Exploration: In offshore drilling, wetgas meters monitor gas streams with liquid droplets. Their compact, durable design suits harsh marine environments, ensuring reliable flow data. This helps operators maintain production efficiency, reduce downtime, and comply with environmental regulations in deepwater projects.

- Digital Oilfield Integration: Wetgas meters with smart sensors support digital oilfields by providing real-time flow data. They integrate with IoT and AI systems, enabling remote monitoring and predictive maintenance. This improves operational efficiency, reduces costs, and supports data-driven decisions in modern oil and gas operations.

- Shale Gas and Unconventional Resources: Wetgas meters are vital for shale gas and unconventional resource extraction, where gas often contains liquids. They provide precise measurements without phase separation, enhancing ROI. Their use supports the growing demand for accurate metering in complex, high-liquid-content reservoirs.

- Industrial Processing: In industries like petrochemicals and power generation, wetgas meters measure gas flow in processing plants. They handle multiphase flows, ensuring accurate billing and compliance with safety standards. Their durability and low maintenance make them ideal for continuous industrial operations.

Recent Developments

1. AMETEK

AMETEK has introduced advanced ultrasonic wet gas flow meters with improved accuracy for challenging gas conditions. Their latest models feature real-time data analytics and enhanced diagnostics for oil & gas applications. The technology reduces uncertainty in multiphase flow measurements, catering to offshore and onshore operations.

2. Apex Instruments Inc.

Apex Instruments has developed compact wet gas meters with high-resolution sensors for low-flow applications. Their new designs focus on minimizing pressure drop while maintaining precision in gas-liquid mixtures. These meters are ideal for emissions monitoring and industrial gas processing.

3. CX Instrument

CX Instrument has launched Coriolis-based wet gas flow meters with multi-parameter measurement capabilities. Their latest innovation includes AI-driven calibration for improved reliability in humid and high-pressure environments. These meters are widely used in the petrochemical and LNG industries.

4. DP Diagnostics

DP Diagnostics has enhanced its differential pressure (DP) wet gas meters with adaptive algorithms for fluctuating flow conditions. Their new models offer better turndown ratios and reduced maintenance needs, making them suitable for shale gas and condensate applications.

5. Dr. Ing. RITTER Apparatebau GmbH & Co. KG

RITTER has introduced thermal mass flow-based wet gas meters with self-cleaning sensors for biogas and landfill applications. Their latest technology ensures long-term stability in corrosive and particulate-laden gas streams.

Conclusion

The Wetgas Meters Market is growing steadily due to rising demand for accurate flow measurement in natural gas production, offshore exploration, and industrial applications. Their ability to handle multiphase flows, integrate with digital systems, and ensure regulatory compliance drives adoption. With increasing focus on energy efficiency and unconventional resources, wetgas meters will remain critical for optimizing operations and meeting global energy needs.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)