Table of Contents

Overview

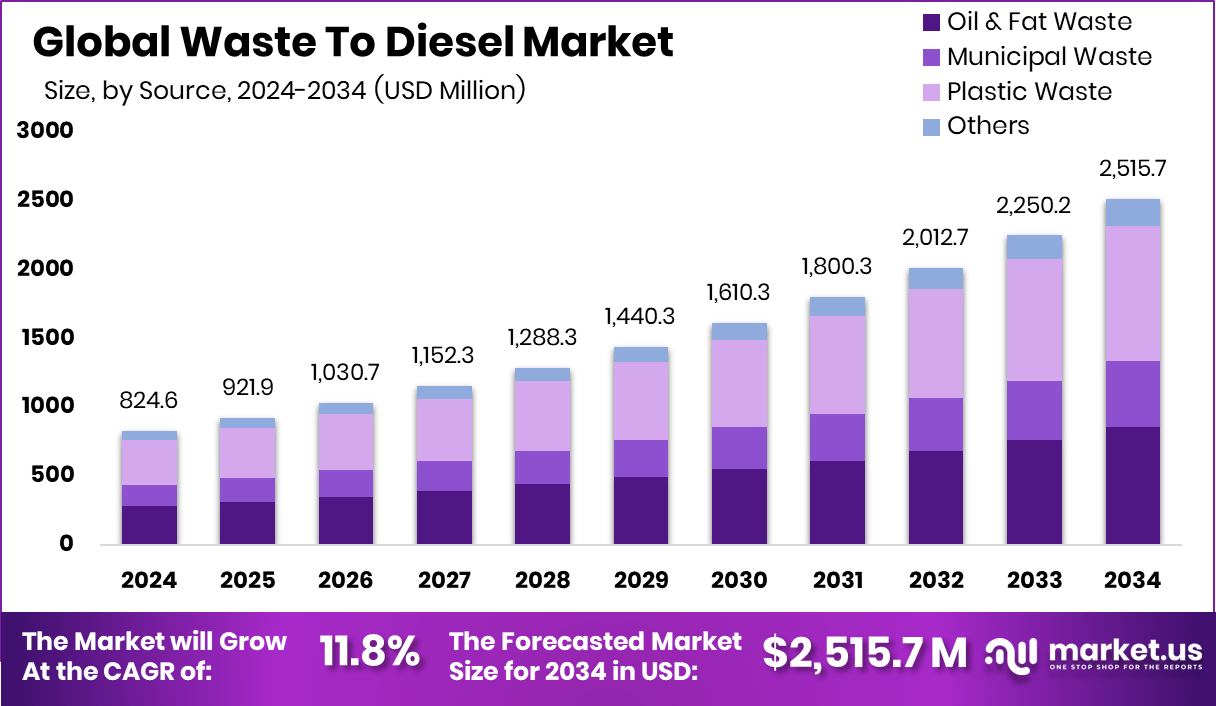

New York, NY – August 21, 2025 – The Global Waste to Diesel Market is projected to reach USD 2,515.7 million by 2034, growing from USD 824.6 million in 2024 at a CAGR of 11.8% from 2025 to 2034. Europe holds a 45.8% market share, driven by robust waste management policies.

Waste to Diesel technology transforms various waste types such as plastic, municipal solid waste, agricultural residues, and industrial by-products into synthetic diesel fuel using thermal and chemical processes like pyrolysis or gasification, followed by catalytic upgrading. This cleaner-burning diesel is compatible with existing diesel engines, providing a sustainable solution for waste management and energy production.

The Waste to Diesel market is gaining traction as a key element of the circular economy, turning waste into a valuable resource. Growing concerns over landfill use, plastic pollution, and the demand for alternative fuels are driving adoption. Supportive policies and funding are accelerating the development of waste-to-energy technologies, which help reduce greenhouse gas emissions and reliance on fossil fuels.

Demand is rising in transportation, construction, and backup power sectors, where diesel remains prevalent. Unlike biodiesel, waste-derived diesel closely resembles fossil diesel, allowing seamless integration without engine modifications, making it ideal for off-grid and remote applications. The U.S. Department of Energy has allocated $3 million to support community-driven waste-to-energy projects for local clean energy solutions. In Europe, Repsol is investing over €800 million in the Tarragona Ecoplanta, a pioneering facility for producing renewable methanol.

Key Takeaways

- The Global Waste To Diesel Market is expected to be worth around USD 2,515.7 million by 2034, up from USD 824.6 million in 2024, and is projected to grow at a CAGR of 11.8% from 2025 to 2034.

- Plastic waste drives a 39.3% share in the waste-to-diesel market.

- Pyrolysis technology leads with a 45.7% share in conversion methods.

- Transportation fuels dominate the application, capturing 48.2% market share globally.

- The regional market in Europe was valued at USD 377.3 million in 2024.

➤ Curious about the content? Explore a sample copy of this report – https://market.us/report/waste-to-diesel-market/request-sample/

Report Scope

| Market Value (2024) | USD 824.6 Million |

| Forecast Revenue (2034) | USD 2,515.7 Million |

| CAGR (2025-2034) | 11.8% |

| Segments Covered | By Source (Oil and Fat Waste, Municipal Waste, Plastic Waste, Others), By Technology (Gasification, Pyrolysis, Depolymerisation, Incineration), By Application (Transportation Fuels, Industrial Fuels, Power Generation, Others) |

| Competitive Landscape | Amec Foster Wheeler, Klean Industries Inc., Plastic2Oil Inc., Reworld, Veolia Environnement, TotalEnergies, Rentech Inc., Enerkem |

➤ Directly purchase a copy of the report – https://market.us/purchase-report/?report_id=154909

Key Market Segments

By Source Analysis

Plastic waste leads the Waste to Diesel market, commanding a 39.3% share in 2024, driven by its abundant availability and suitability as a feedstock. The global surge in non-biodegradable plastics, particularly polyethylene and polypropylene, makes plastic waste ideal for thermochemical processes like pyrolysis, which efficiently converts it into high-quality diesel-like fuels.

Rising concerns over plastic pollution, coupled with stricter regulations on disposal and increasing landfill costs, have spurred governments and industries to prioritize plastic waste valorization. The low-sulfur diesel produced from plastics aligns with clean fuel standards, offering an environmentally friendly alternative to fossil diesel. With ongoing restrictions on landfilling and incineration, the plastic waste segment is poised to maintain its dominance.

By Technology Analysis

Pyrolysis holds a leading 45.7% share in the Waste to Diesel market’s technology segment in 2024, owing to its versatility and efficiency in converting mixed waste into diesel-grade fuels. Its ability to process diverse waste streams without extensive pre-sorting makes it widely adopted in both developed and developing regions.

Operating in oxygen-free conditions, pyrolysis minimizes emissions and ensures controlled thermal breakdown of waste. The technology’s modular scalability supports decentralized fuel production, particularly in areas with limited fuel access. The diesel produced closely mirrors conventional diesel, requiring no engine modifications, which enhances its commercial appeal. As demand for sustainable waste-to-fuel solutions grows, pyrolysis remains the preferred technology.

By Application Analysis

Transportation fuels dominate the Waste to Diesel market, capturing a 48.2% share in 2024, fueled by strong demand for alternative diesel in freight, logistics, and public transport. Waste-derived diesel, primarily from pyrolysis, serves as a cleaner-burning substitute that meets existing fuel standards, seamlessly integrating into current vehicle fleets and infrastructure.

Stricter carbon emission regulations and the push to reduce fossil fuel dependency have boosted its adoption. In regions reliant on diesel imports, waste-to-diesel offers a cost-effective and sustainable solution. The abundance of waste feedstocks and ease of integration into existing fuel networks solidify transportation’s position as the primary application for waste-derived diesel.

Regional Analysis

Europe leads the global Waste to Diesel market in 2024, holding a 45.8% share valued at USD 377.3 million, driven by stringent waste management policies and circular economy initiatives. Robust landfill diversion targets and plastic waste reduction programs have spurred investments in advanced waste-to-fuel technologies like pyrolysis across Western and Central Europe.

North America follows, with growing adoption fueled by environmental regulations and demand for fossil diesel alternatives in industrial and transport sectors. Asia Pacific is emerging, particularly in urban areas with increasing waste volumes. The Middle East & Africa and Latin America, while still developing, show potential through growing awareness and pilot projects, but contribute smaller market shares compared to Europe.

Top Use Cases

- Transportation Fuel Alternative: Waste-to-diesel technology converts plastic and municipal waste into diesel fuel, ideal for trucks, buses, and ships. It’s a cleaner-burning option that works with existing engines, reducing reliance on fossil fuels and supporting sustainable transport in urban and remote areas.

- Industrial Power Generation: Waste-derived diesel powers generators in industries like construction and manufacturing. Its compatibility with standard diesel engines makes it a cost-effective, eco-friendly choice for off-grid sites, reducing waste disposal costs and environmental impact.

- Waste Management Solution: Converting municipal solid waste and plastics into diesel tackles landfill overflow and plastic pollution. This process supports circular economy goals by turning waste into a valuable resource, helping cities manage waste sustainably.

- Remote Community Energy: Waste-to-diesel plants provide affordable fuel for remote areas with limited access to traditional energy sources. Using local waste as feedstock, these communities can generate diesel for vehicles and power, promoting energy independence.

- Agricultural Equipment Fuel: Farmers can use waste-derived diesel to power tractors and other machinery. This sustainable fuel, made from agricultural residues and plastic waste, lowers costs and supports eco-friendly farming practices without needing engine modifications.

Recent Developments

1. Amec Foster Wheeler

Amec Foster Wheeler was acquired by John Wood Group. The company continues to advance waste-to-energy and conversion technologies under the Wood brand. Their focus has shifted towards integrating plastic waste conversion processes with carbon capture and storage (CCS) to produce low-carbon diesel alternatives.

2. Klean Industries Inc.

Klean Industries is actively promoting its “KleanLoop” process, which integrates pyrolysis for converting waste tires and plastics into diesel, naphtha, and recovered carbon black. A significant recent development is their partnership with a Scandinavian entity to deploy a large-scale tire pyrolysis plant.

3. Plastic2Oil Inc.

Plastic2Oil, a subsidiary of Clean Vision Corporation, is advancing its proprietary pyrolysis technology to convert unwashed, unsorted plastic waste into ultra-low sulfur diesel. A key recent development is their strategic shift to a build-own-operate model for larger facilities, moving beyond just technology licensing.

4. Reworld (Formerly Covanta)

Rebranded as Reworld in 2024, the company is a leader in waste-to-energy but is expanding into advanced recycling and conversion technologies. Their recent development focuses on integrating pyrolysis units alongside their existing energy-from-waste facilities. This allows them to process non-recyclable plastics, extracting valuable chemicals and diesel-range fuels before combusting the remaining waste for energy.

5. Veolia Environnement

Veolia is leveraging its global waste management footprint to develop advanced chemical recycling projects, including waste-to-diesel pathways. A major recent development is their focus on building large-scale pyrolysis plants, such as the one in Finland, to transform mixed plastic waste into pyrolysis oil. This oil is a direct precursor for refining into diesel.

Conclusion

The Waste-To-Diesel Market offers a promising solution to global waste and energy challenges. By transforming plastic, municipal, and agricultural waste into clean diesel, it supports sustainable transportation, industrial power, and waste management. With growing demand for alternative fuels and stricter environmental regulations, the market is set to expand, driving innovation and economic benefits.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)