Table of Contents

Overview

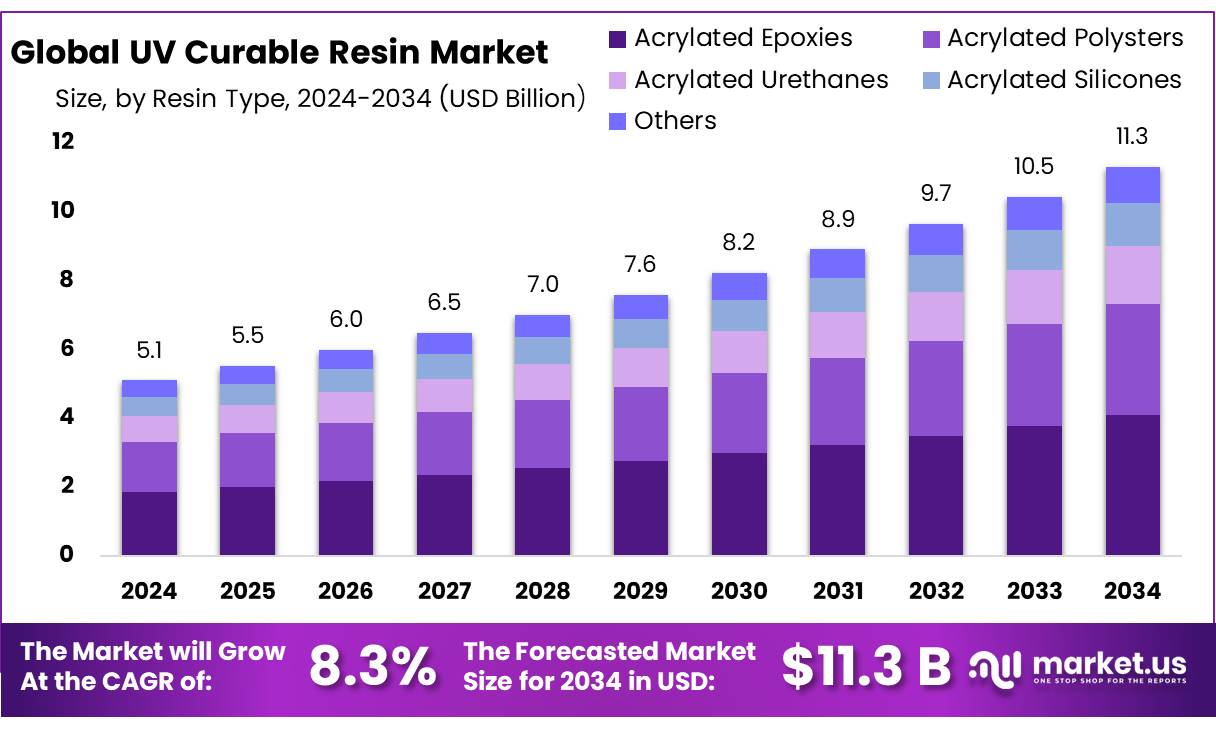

New York, NY – August 08, 2025 – The Global UV Curable Resin Market is projected to reach USD 11.3 billion by 2034, up from USD 5.1 billion in 2024, with a CAGR of 8.3% from 2025 to 2034. In 2024, the Asia Pacific region led the market, holding a 45.9% share and generating USD 2.3 billion in revenue.

UV curable resin concentrates are formulations of pre-polymers, monomers, photoinitiators, and additives that rapidly polymerize under ultraviolet light. Widely used in coatings, adhesives, inks, and 3D printing, these systems offer nearly 100% reactive solids, reducing volatile organic compound (VOC) emissions and energy use compared to solvent-based or thermal-curing alternatives.

Market growth is driven by stringent environmental regulations promoting low-VOC materials, such as those enforced by the U.S. Environmental Protection Agency (EPA), which have shifted industries toward UV-curable resins. Additionally, rising demand for eco-friendly products and faster production processes is boosting adoption.

In India, the chemical industry is a key focus, contributing 7% to GDP in 2022, with over 80,000 commercial chemicals produced and more than five million jobs created. Under initiatives like Make in India and Aatmanirbhar Bharat, the sector aims to attract INR 8 lakh crore (~USD 100 billion) in investments by 2025. The revised Market Access Initiative supports smaller chemical companies in expanding into global export markets.

Key Takeaways

- The Global UV Curable Resin Market size is expected to be worth around USD 11.3 billion by 2034, from USD 5.1 billion in 2024, growing at a CAGR of 8.3%.

- Acrylated Epoxies held a dominant market position in the UV curable resin market, capturing more than a 36.2% share.

- Monomers held a dominant market position in the UV curable resin market, capturing more than a 48.9% share.

- Coating held a dominant market position in the UV curable resin market, capturing more than a 42.6% share.

- Asia Pacific (APAC) region held a commanding position in the global UV curable resin market, capturing more than 45.9% of the total market share, equivalent to a market value of approximately USD 2.3 billion.

➤ Curious about the content? Explore a sample copy of this report – https://market.us/report/global-uv-curable-resin-market/request-sample/

Report Scope

| Market Value (2024) | USD 5.1 Billion |

| Forecast Revenue (2034) | USD 11.3 Billion |

| CAGR (2025-2034) | 8.3% |

| Segments Covered | By Resin Type (Acrylated Epoxies, Acrylated Polysters, Acrylated Urethanes, Acrylated Silicones, Others), By Composition ( Monomers, Photoinitiators, Oligomers, Coinitiators, Others), By Application (Coating, Printing, Adhesives and Sealants, Others) |

| Competitive Landscape | Alberdingk Boley GmbH, Allnex Netherlands B.V., Arkema Group, Astorg (IGM Resins), BASF SE, Covestro AG, DIC Corporation, IGM Resins, Jiangsu Litian Technology Co., Ltd., Mitsubishi Chemical Europe GmbH (Nippon-Gohsei), Miwon Specialty Chemical Co., Ltd., Resonac Holdings Corporation, SOLTECH LTD, TOAGOSEI CO., LTD., Wanhua Chemical Group Co., Ltd. |

➤ Directly purchase a copy of the report – https://market.us/purchase-report/?report_id=153821

Key Market Segments

By Resin Type Analysis

In 2024, Acrylated Epoxies commanded over 36.2% of the UV curable resin market, owing to their exceptional performance attributes, including robust adhesion, high mechanical strength, and excellent resistance to chemicals and heat. These resins are extensively utilized in coatings for electronics, wood, automotive, and industrial applications, where precision and durability are critical.

Their rapid curing under UV light suits high-speed production environments, particularly in advanced manufacturing. Acrylated epoxies’ ability to form tough, cross-linked films makes them ideal for demanding sectors like electronics, especially for printed circuit boards and protective coatings. This segment is projected to maintain its dominance into 2025, fueled by growing applications and alignment with low-VOC environmental standards.

By Composition Analysis

In 2024, Monomers captured over 48.9% of the UV curable resin market, serving as critical reactive diluents that enable precise control over viscosity, cure speed, and mechanical properties. Their adaptability in customizing characteristics like hardness, adhesion, and surface finish makes them indispensable in coatings, inks, and adhesives.

Monomers are particularly favored in fast-curing applications such as packaging, electronics, and automotive coatings, where efficiency and surface quality are paramount. The segment’s dominance is bolstered by increasing demand for low-VOC materials and tailored resin formulations. As industries prioritize sustainable, energy-efficient processes, monomers’ role in enabling low-temperature curing and high throughput ensures continued demand.

By Application Analysis

In 2024, Coatings accounted for over 42.6% of the UV curable resin market, driven by their extensive use in wood processing, automotive refinishing, electronics, and metal finishing. UV-curable coatings are favored for their rapid curing, durability, and eco-friendly profile, with low VOC emissions. In the wood industry, they provide high gloss and wear resistance for flooring and furniture, while in electronics, they protect sensitive components while enhancing performance.

In automotive applications, UV coatings offer scratch and chemical resistance, and their instant curing under UV light reduces processing time and energy costs, ideal for high-speed manufacturing. As sustainability gains importance, UV coatings’ compliance with stringent environmental standards ensures their continued dominance.

Regional Analysis

In 2024, the Asia Pacific (APAC) region solidified its leadership in the global UV curable resin market, accounting for over 45.9% of the market share, with a valuation of approximately USD 2.3 billion. This dominance is driven by the region’s strong industrial ecosystem, particularly in key markets like China, India, Japan, and South Korea, which are major hubs for electronics, automotive, furniture, and packaging production.

The widespread use of UV curable technologies in these sectors stems from the demand for high-performance, eco-friendly coatings, inks, and adhesives that provide rapid curing and lower energy use. China remains the primary driver of regional demand, fueled by its vast electronics and furniture industries. India is experiencing significant growth, propelled by rising investments in infrastructure and automotive manufacturing.

In Japan and South Korea, the adoption of UV-curable systems is boosted by advanced technological applications in precision electronics and high-quality packaging. Furthermore, stringent government regulations promoting low-VOC solutions are accelerating the transition from solvent-based to UV-curable systems, enhancing market growth across the region.

Top Use Cases

- Coatings for the Automotive Industry: UV curable resins provide durable, scratch-resistant coatings for car parts like dashboards and exterior panels. They cure quickly under UV light, ensuring fast production and high-quality finishes. These eco-friendly coatings reduce harmful emissions, meeting strict environmental standards while offering excellent adhesion and chemical resistance for long-lasting vehicle protection.

- Packaging Industry Applications: UV curable resins are widely used in food and pharmaceutical packaging for coatings, inks, and adhesives. They ensure quick-drying, high-quality prints with vibrant colors and strong adhesion. These resins are eco-friendly, emitting low volatile organic compounds (VOCs), making them ideal for sustainable packaging solutions with enhanced durability.

- Electronics Manufacturing: UV curable resins are used in electronics for encapsulating and coating circuit boards. They provide insulation, moisture resistance, and protection from environmental damage. Their fast-curing nature speeds up production, while their durability ensures reliable performance in devices like smartphones and computers, supporting compact and efficient designs.

- 3D Printing Applications: UV curable resins are key in 3D printing for creating precise, high-resolution prototypes and parts. They cure quickly under UV light, enabling faster printing and detailed designs. These resins offer flexibility and strength, making them suitable for industries like automotive, medical, and aerospace for functional and durable components.

- Adhesives for Medical Devices: UV curable resins are used in medical device manufacturing for bonding components like catheters and syringes. They provide strong, reliable adhesion with quick curing, ensuring sterile and safe assembly. These resins are biocompatible and resistant to chemicals, meeting strict medical standards for durability and safety in healthcare applications.

Recent Developments

1. Alberdingk Boley GmbH

Alberdingk Boley has expanded its UV curable resin portfolio with eco-friendly, low-VOC formulations for coatings and adhesives. Their latest innovations focus on high-performance resins for flexible packaging and wood coatings, offering fast curing and enhanced durability. The company emphasizes sustainability, with bio-based raw materials in development.

2. Allnex Netherlands B.V.

Allnex introduced Ebecryl 222, a new UV-curable oligomer for automotive and industrial coatings, providing excellent adhesion and chemical resistance. They also launched EBECRYL 350, a low-viscosity resin for 3D printing and ink applications, enhancing printability and mechanical properties.

3. Arkema Group

Arkema’s Sartomer division released CN9006, a high-efficiency UV-curable resin for 3D printing and electronics, improving toughness and flexibility. They also developed UV LED-curable resins for energy-efficient curing in the automotive and packaging industries.

4. Astorg (IGM Resins)

IGM Resins launched Omnirad BL 403, a breakthrough photoinitiator for UV LED curing, enabling faster curing in thick coatings. They also expanded their ResiLite portfolio with low-odor, high-performance resins for graphic arts and industrial applications.

5. BASF SE

BASF introduced Laromer LR 9017, a UV-curable resin for automotive refinish coatings with superior scratch resistance. They also developed Ultra-rapid curing resins for digital printing, reducing energy consumption and improving production efficiency.

Conclusion

The UV Curable Resin Market is growing rapidly due to its eco-friendly nature, fast curing, and versatile applications. Industries like automotive, packaging, electronics, and 3D printing drive demand for these sustainable, high-performance materials. With increasing environmental regulations and focus on efficiency, UV curable resins are set to expand, offering durable, low-VOC solutions across diverse sectors.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)