Table of Contents

Overview

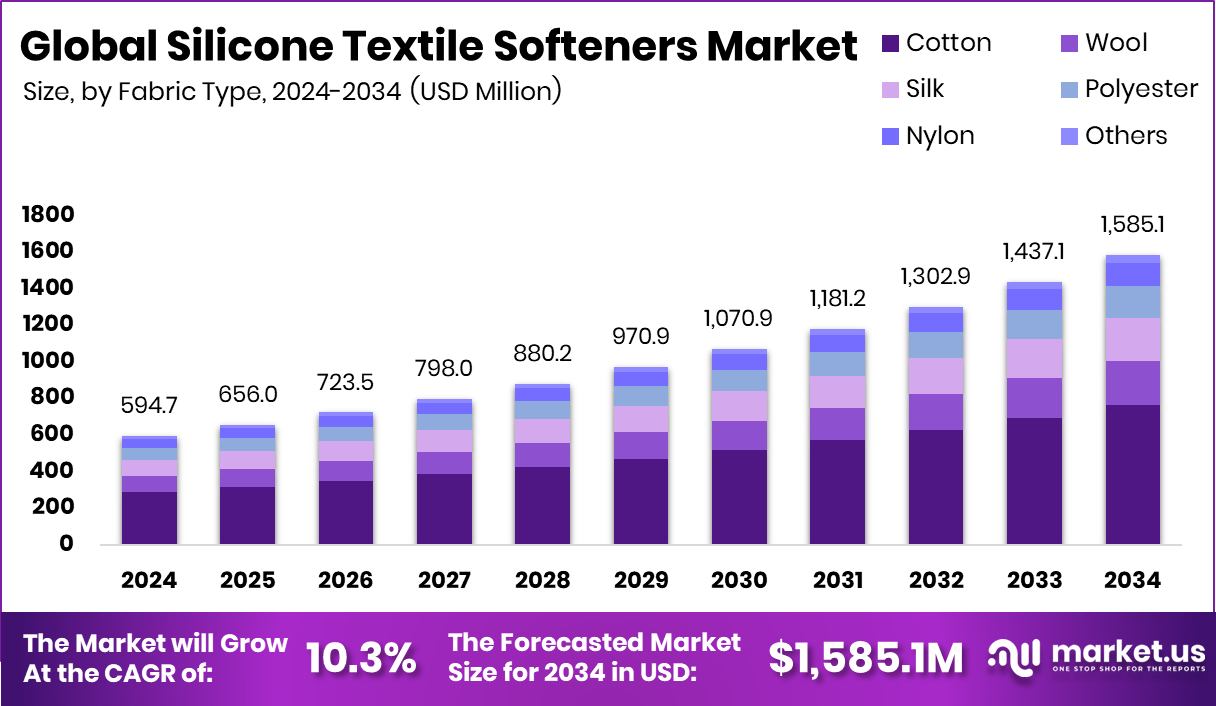

New York, NY – Nov 04, 2025 – The global market for silicone textile softeners—specialty chemical agents applied to fabrics to improve softness, smoothness, and flexibility—is projected to grow from USD 594.7 million in 2024 to approximately USD 1,585.1 million by 2034, at a CAGR of 10.3% from 2025 through 2034. In Europe alone, the market is valued at USD 225.3 million, accounting for 37.90% of the regional segment.

These softeners enhance garments, home textiles, and industrial fabrics by forming a thin lubricating layer around fibers, reducing friction, improving drape and wrinkle recovery, and extending fabric life across materials such as cotton, polyester, blends, and technical textiles. Growth is driven by the booming apparel and textile sector, as well as rising consumer demand for high-quality, comfortable, and wrinkle-resistant fabrics.

Notably, a French startup, Syntetica, secured €4.2 million to scale nylon recycling technology, reflecting how material innovation and textile-chemistry funding are aligning for sustainable growth.

As governments and industries push for eco-friendly processing, opportunities are emerging around bio-based silicones and low-impact formulations, positioning silicone softeners at the convergence of performance finishing and sustainable textile chemistry.

➤ Click the sample report link for complete industry insights: https://market.us/report/global-silicone-textile-softeners-market/request-sample/

Key Takeaways

- The Global Silicone Textile Softeners Market is expected to be worth around USD 1,585.1 million by 2034, up from USD 594.7 million in 2024, and is projected to grow at a CAGR of 10.3% from 2025 to 2034.

- In the Silicon Textile Softeners Market, cotton fabric holds 48.3% due to widespread global use.

- Modified silicone softeners dominate the silicone textile softeners market with a 48.8% share, driven by superior performance.

- Fashion and apparel lead the silicone textile softeners market at 49.2%, reflecting strong consumer lifestyle demand.

- Europe captured a 37.90% share of the Silicone Textile Softeners Market, worth USD 225.3 Mn.

➤ Directly purchase a copy of the report – https://market.us/purchase-report/?report_id=159753

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2024) | USD 594.7 Million |

| Forecast Revenue (2034) | USD 1,585.1 Million |

| CAGR (2025-2034) | 10.3% |

| Segments Covered | By Fabric Type (Cotton, Wool, Silk, Polyester, Nylon, Others), By Type (Inactive Silicone Softener, Active Silicone Softener, Modified Silicone Softener), By End-use (Fashion and Apparel, Home Furnishing, Healthcare, Textiles, Aerospace, Automotive, Others) |

| Competitive Landscape | Cosmo Specialty Chemicals, Tian Sheng, Nicca, Momentive Performance Materials Inc., Fineotex, Dow Chemicals, Shin-Etsu, Wacker Chemicals AG, Sarex Chemicals, Rudolf Group |

Key Market Segments

By Fabric Type Analysis

In 2024, cotton dominated the By Fabric Type segment of the Silicone Textile Softeners Market, capturing a 48.3% share. This strong position stems from its widespread use in global apparel and home textiles, where comfort, softness, and durability remain key priorities. Silicone softeners play a vital role in enhancing cotton’s natural smoothness, reducing wrinkles, and extending the fabric’s lifespan. Their application ensures improved drape and a premium hand feel across various cotton-based fabrics.

The continued consumer preference for breathable and versatile cotton materials—spanning casual wear, formal garments, and household textiles—further sustains this dominance. With both premium and mass-market brands relying on cotton’s performance and comfort, its leading role in driving the use of silicone softeners remains secure, reinforcing cotton as the most influential fabric type in the evolving global textile finishing industry.

By Type Analysis

In 2024, Modified Silicone Softeners dominated the By Type segment of the Silicone Textile Softeners Market, accounting for a 48.8% share. Their leading position is driven by the ability to provide exceptional softness, smooth texture, and enhanced durability while preserving the fabric’s breathability.

These softeners are preferred for their superior compatibility with diverse fibers, including cotton, polyester, and blends, delivering better performance than conventional formulations. Their role in improving wrinkle recovery, elasticity, and overall hand-feel has made them essential in apparel and home textile production.

As consumer demand rises for comfortable, long-lasting, and premium-quality fabrics, the adoption of modified silicone softeners continues to expand globally. This sustained preference highlights their importance in achieving high-performance textile finishes that meet evolving expectations for both comfort and durability in modern fabric applications.

By End-use Analysis

In 2024, the Fashion and Apparel segment dominated the By End-use category of the Silicone Textile Softeners Market, capturing a 49.2% share. This leadership stems from the rising consumer demand for comfortable, wrinkle-resistant, and high-quality garments.

Silicone softeners significantly enhance the texture, drape, and durability of fabrics, making them indispensable in modern apparel finishing. Their application ensures smoother, softer textiles that maintain a premium look and feel over time. The segment’s growth is further supported by evolving fashion trends that prioritize both comfort and performance, driving widespread adoption of silicone-based finishing treatments.

From everyday wear to luxury clothing, manufacturers increasingly rely on these softeners to deliver superior tactile qualities and fabric resilience. As global apparel markets expand, the Fashion and Apparel segment remains central to shaping innovation and sustaining the strong market presence of silicone textile softeners.

Regional Analysis

The Silicone Textile Softeners Market displays strong regional diversity across major global regions. In 2024, Europe led the market with a 37.90% share, valued at USD 225.3 million, supported by its advanced textile industry that prioritizes premium quality, innovation, and sustainability in fabric finishing.

North America follows with steady growth, driven by increasing demand for high-performance and comfortable textiles in apparel and home décor. Asia Pacific, home to key textile manufacturing nations like China and India, remains the fastest-growing region, propelled by large-scale production and expanding consumer markets for both cotton and synthetic fabrics.

Meanwhile, Latin America and the Middle East & Africa show progressive development through rising apparel output and the adoption of modern finishing technologies. These dynamics highlight Europe’s dominant position built on eco-friendly innovation, while Asia Pacific’s rapid growth reflects its expanding manufacturing capacity—together shaping a balanced and globally expanding silicone textile softeners market.

Top Use Cases

- Improving softness and hand-feel in fabrics: Silicone softeners are applied in the finishing stage to impart a smooth, luxurious touch to textiles. They form a thin lubricating layer around fibers, reducing friction and making garments feel softer and drape better.

- Enhancing wrinkle recovery and durability: These softeners help fabrics “bounce back” after wearing and washing, supporting performance in garments that need to look neat. As one source puts it: Silicones penetrate deeply into fabric fibers, creating a lasting effect.”

- Boosting hydrophilicity and moisture management: Modified silicone softeners (especially those with polyether segments) can make fabrics more breathable and better at drying, improving comfort in textiles like towels or active wear.

- Providing antistatic and dust-repellent surface properties: On fabrics where static cling or dust attraction is a problem, silicone softeners help the textile shed charge and resist dust pickup, improving appearance and comfort.

- Finishing synthetic and blended fabrics for a premium feel: For synthetic fibers (polyester, acrylic) and blends, silicone softeners deliver a more natural touch and luxury finish—especially useful in fashion and home textiles.

- Special finishes for home textiles (e.g., terry, upholstery): In home-textile applications like towels, bedding, or upholstery, silicone softeners give a plush, full, long-lasting hand-feel and help maintain appearance after many washes.

Recent Developments

- In May 2024, Dow’s innovations in silicone technologies were recognized with awards (e.g., DOWSIL™ IE-9100 emulsion for performance apparel), but this is about textile finishing broadly, not explicitly a new textile-softener product.

- In May 2024, Shin-Etsu announced that it would build a new plant for silicone products in Zhejiang Province, China. The site in Pinghu City will cover about 40,000 m² and is set for completion in February 2026. The plant will produce functional silicone emulsions and environmentally friendly silicone products in addition to existing general-purpose silicone emulsions.

Conclusion

The silicone textile softeners market continues to evolve with advancements in sustainable chemistry and performance-based formulations. Growing awareness about eco-friendly finishing processes and consumer preference for comfortable, durable, and premium-quality fabrics are shaping industry trends. Manufacturers are focusing on bio-based and modified silicone technologies that enhance softness while ensuring environmental compliance.

With innovations in textile finishing and increasing collaboration between chemical producers and apparel brands, silicone softeners are becoming essential in delivering high-value textiles that combine comfort, quality, and sustainability. The market’s future lies in balancing performance enhancement with environmental responsibility and technological innovation.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)