Table of Contents

Overview

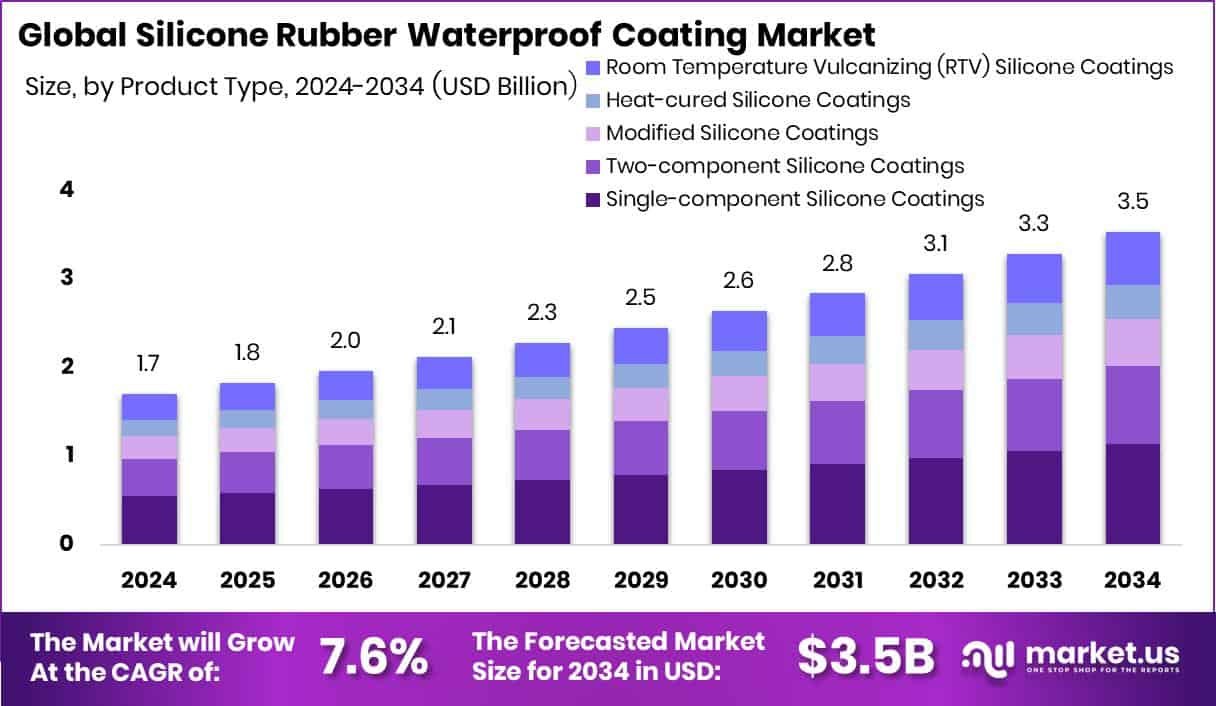

New York, NY – Nov 28, 2025 – The Silicone Rubber Waterproof Coating Market is on a strong growth path, projected to reach USD 3.5 billion by 2034, rising from USD 1.7 billion in 2024, with a 7.6% CAGR between 2025 and 2034. Asia-Pacific leads with a 45.9% share, generating close to USD 0.7 billion, mainly supported by large-scale construction activity and infrastructure expansion.

Silicone rubber waterproof coatings are high-performance protective layers made from silicone elastomers. They create a seamless, flexible film that resists water, UV radiation, heat, and extreme weather. As a result, they are widely used on roofs, exterior walls, metal structures, insulation panels, and prefabricated buildings. Their ability to stretch without cracking and provide long service life makes them suitable for energy-efficient and low-maintenance construction projects.

Market growth is closely tied to climate-resilient building practices, faster construction timelines, and increasing adoption of modular and prefab structures. Demand is also supported by public and private investments aimed at improving construction efficiency and workforce skills. In Europe, modernisation efforts are evident through €38 million in funding for a German SaaS construction platform and USD 1.2 million in seed funding for an AI-driven construction data system, encouraging smarter material selection and lifecycle optimisation.

Government initiatives further strengthen demand, including plans to train workers for building 1.5 million new homes and a USD 20 million investment in modular construction development, expanding opportunities for waterproof silicone coating applications across faster and cleaner building systems.

➤ Click the sample report link for complete industry insights: https://market.us/report/global-silicone-rubber-waterproof-coating-market/request-sample/

Key Takeaways

- The Global Silicone Rubber Waterproof Coating Market is expected to be worth around USD 3.5 billion by 2034, up from USD 1.7 billion in 2024, and is projected to grow at a CAGR of 7.6% from 2025 to 2034.

- Single-component products lead the silicone rubber waterproof coating market with a 32.1% share, driven by easy use.

- The construction and building segment dominates the silicone rubber waterproof coating market with a 35.6% demand share.

- Asia-Pacific demand strengthens due to infrastructure growth worth USD 0.7 Bn, 45.9% of the segment.

➤ Directly purchase a copy of the report – https://market.us/purchase-report/?report_id=166308

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2024) | USD 1.7 Billion |

| Forecast Revenue (2034) | USD 3.5 Billion |

| CAGR (2025-2034) | 7.6% |

| Segments Covered | By Product Type (Single-component Silicone Coatings, Two-component Silicone Coatings, Modified Silicone Coatings, Heat-cured Silicone Coatings, Room Temperature Vulcanizing (RTV) Silicone Coatings), By Application (Construction and Building, Aerospace and Defense, Automotive, Electronics, Marine, Medical Devices, Others) |

| Competitive Landscape | AkzoNobel, Sika Mortars, PPG, Sherwin-Williams, Grupo Puma, Koster, BASF, Weber Building Solutions, Davco, Henkel |

Key Market Segments

By Product Type Analysis

In 2024, single-component silicone coatings maintained a leading position in the by-product type segment of the silicone rubber waterproof coating market, holding a 32.1% market share. Their dominance was mainly driven by ease of use, as these coatings do not require mixing and cure directly after application, helping reduce labor time and on-site complexity. This made them especially attractive for projects with tight deadlines and limited skilled labor availability.

Demand was further strengthened by the rising need for quick-to-apply waterproofing systems in residential, commercial, and industrial buildings. Large infrastructure projects and modular construction sites increasingly favor solutions that support faster installation without compromising performance.

Single-component silicone coatings also provide smooth, joint-free surfaces with strong flexibility, allowing them to handle temperature changes without cracking. Their strong adhesion to concrete, metal surfaces, insulation boards, and prefabricated panels improved their reliability across diverse applications. Long service life, low maintenance needs, and consistent performance in demanding environments reinforced their continued preference in modern construction and infrastructure developments.

By Application Analysis

In 2024, the Construction and Building segment led the Silicone Rubber Waterproof Coating Market by application, capturing a 35.6% market share. This dominance was mainly supported by widespread usage on rooftops, external walls, insulation systems, joints, and prefabricated building components where reliable, long-term water protection is required.

Strong material performance played a key role in this leadership. Silicone rubber coatings offer excellent flexibility, resistance to UV exposure, and stability under high temperatures, making them suitable for both new construction projects and refurbishment work. These properties allow structures to withstand weather stress while maintaining performance over time.

Rising demand for moisture-resistant, energy-efficient, and low-maintenance buildings further boosted adoption across residential housing, commercial properties, and public infrastructure. The ability of these coatings to adhere well to multiple surfaces, combined with their long service life, reduced repair needs and lifecycle costs. As a result, the Construction and Building segment maintained steady demand and remained the primary application area within the market.

Regional Analysis

Asia-Pacific remained the leading region in the Silicone Rubber Waterproof Coating Market, holding a 45.9% share valued at USD 0.7 billion. This strong position was supported by high construction activity, expanding use of prefabricated infrastructure, and increasing adoption of long-life waterproofing solutions across residential, commercial, and industrial buildings. Large housing programs, growing awareness of water protection, and demand for durable surface materials further strengthened regional growth.

North America showed stable demand, mainly driven by renovation projects, roof replacement cycles, climate-resilient construction standards, and ongoing spending on property maintenance.

Europe continued to prefer high-performance waterproof coatings due to strict energy efficiency rules and building protection requirements, particularly in moisture-prone and cold-climate areas.

The Middle East & Africa saw rising usage in industrial sites, logistics facilities, and infrastructure projects, where heat resistance and UV durability are critical. Latin America experienced steady growth from urban housing expansion, repair-focused waterproofing needs, and long-term building preservation initiatives.

Top Use Cases

- Flat and Sloped Roof Waterproofing: Silicone coatings are widely used on flat and low-slope roofs (commercial, industrial, and residential). They create a seamless, water-tight membrane that resists ponding water — i.e. water that collects on the roof. This helps prevent leaks and water damage over many years.

- Waterproofing Walls, Basements, Balconies, Terraces & Wet Areas: Silicone waterproof coatings can be applied on exterior and interior walls, basements, balconies, bathrooms, kitchens, and other moisture-prone areas. This prevents seepage, dampness, and internal water damage.

- Protection of Metal Roofs, Tanks and Industrial Surfaces: Because silicone coatings handle extreme temperatures and resist weathering, chemicals, and UV exposure, they are ideal for metal roofs, storage tanks, and industrial roofs or structures.

- Extending Life of Existing Roofs — Roof Restoration & Maintenance: Instead of tearing off an old roof, applying silicone coating over the existing surface can restore waterproofing and extend roof life significantly. This is a cost-effective alternative to full roof replacement.

- Weatherproofing in Harsh Climates — High Temperature, UV & Rain Protection: Silicone coatings resist heat, UV radiation, weathering, and chemical exposure. This makes them suitable for harsh climates — very hot, sunny, or rainy environments.

- Waterproofing Irregular/Complex Surfaces and Prefab/Modular Structures: Silicone coatings can be applied on irregular roofs or surfaces — not just flat ones — making them useful for sloping roofs, terraces, decorative roofs, and prefab or modular construction projects.

Recent Developments

- In June 2025, PPG highlighted new high-performance architectural and metal coatings at a global architecture and building design event. These coatings were developed for exterior building components such as metal panels, facades, and structural elements, focusing on long-term weather resistance, durability, and environmental exposure protection.

- In October 2024, at METALCON 2024, AkzoNobel’s Coil & Extrusion Coatings team displayed new applications of CERAM-A-STAR® — a “silicone-modified polyester” coating — including on exterior board & batten metal panels. The showcase emphasized realistic finishes, durability, UV resistance, and performance backed by a warranty.

Conclusion

The Technical Insulation Market continues to evolve as industries place stronger emphasis on energy efficiency, safety, and long-term asset protection. Insulation solutions play a critical role in reducing heat loss, controlling condensation, and protecting equipment across construction, industrial, and energy applications.

Growing awareness around sustainable building practices and operational efficiency is encouraging wider adoption of advanced insulation materials. Technological improvements are supporting better thermal performance, fire resistance, and durability under challenging conditions. In parallel, renovation activities and infrastructure upgrades are increasing the need for reliable insulation systems.

As regulations around energy conservation and workplace safety tighten, technical insulation remains an essential component for modern buildings and industrial facilities, supporting operational reliability, environmental goals, and long-term maintenance reduction.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)