Table of Contents

Overview

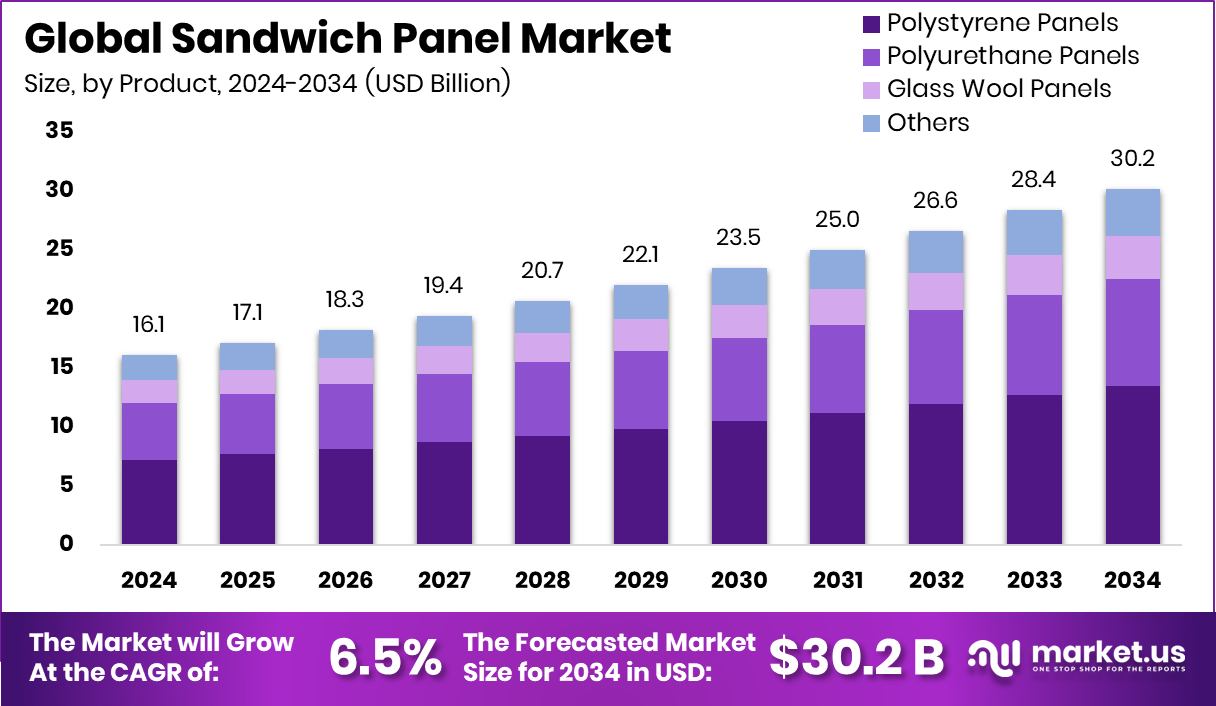

New York, NY – February 20, 2026 – The global sandwich panel market, valued at USD 16.1 billion in 2024 and projected to reach USD 30.2 billion by 2034 at a 6.5% CAGR, continues to expand as Europe maintains a 36.80% share worth USD 5.9 billion. Sandwich panels combine two rigid outer layers with an insulating core, offering strength, thermal efficiency, and sound control in a single lightweight structure. Their fast installation and energy-saving benefits make them essential in warehouses, industrial facilities, healthcare spaces, commercial buildings, and modular construction.

Market momentum is strongly shaped by advances in eco-friendly insulation and material innovation. A notable example is the $1.5 million RPI research grant dedicated to developing hemp-based insulated siding, signaling rising interest in low-carbon and bio-based construction solutions. On the production side, demand growth is evident as an insulated panel manufacturer invests $24 million in a new facility in Monroe County to scale output. Similarly, Sips Eco Panels’ £1 million expansion to double its workforce highlights operational growth driven by increasing orders for efficient building systems.

Broader institutional priorities also influence market direction. The $20 million in new giving at Brown to support diversity, equity, and inclusion contributes to expanding educational infrastructure where modern, high-performance buildings increasingly rely on insulated panel systems.

➤ Click the sample report link for complete industry insights: https://market.us/report/global-sandwich-panel-market/request-sample/

Key Takeaways

- The Global Sandwich Panel Market is expected to be worth around USD 30.2 billion by 2034, up from USD 16.1 billion in 2024, and is projected to grow at a CAGR of 6.5% from 2025 to 2034.

- In the Sandwich Panel Market, Polystyrene Panels led the By Product segment with 44.7%, driven by cost efficiency and thermal insulation performance.

- Within the Sandwich Panel Market, Walls and Floors dominated the By Application segment at 34.6%, supported by rapid industrial and commercial construction demand.

- Across the Sandwich Panel Market, Non-residential end-use accounted for 67.8%, fueled by warehouses, factories, and large infrastructure projects.

- Europe’s Sandwich Panel Market reached 36.80% share, generating USD 5.9 Bn revenue region.

➤ Directly purchase a copy of the report – https://market.us/purchase-report/?report_id=173148

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2024) | USD 16.1 Billion |

| Forecast Revenue (2034) | USD 30.2 Billion |

| CAGR (2025-2034) | 6.5% |

| Segments Covered | By Product (Polystyrene Panels, Polyurethane Panels, Glass Wool Panels, Others), By Application (Walls and Floors, Roofs, Cold Storage, Others), By End-use (Residential, Non-residential) |

| Competitive Landscape | Kingspan Group, Owens Corning, Isopan, PFB Corporation, Metecno Group, RAY-CORE SIPs, American Insulated Panel, Metl-Span, KPS Global, American Buildings Company |

Key Market Segments

By Product

Polystyrene panels remained the dominant product in the Sandwich Panel Market in 2024, securing a 44.7% share. Their leadership stems from a mix of affordability, lightweight construction, and dependable thermal insulation, making them ideal for builders managing tight budgets and strict timelines. The closed-cell structure of polystyrene helps reduce heat transfer, supporting global energy-efficiency goals and aligning with updated building codes. These panels are especially valued in commercial and industrial environments where fast, efficient installation is essential. Their ease of transportation and compatibility with prefabricated building systems further elevate their appeal in large-scale projects.

As global construction accelerates and demand rises for insulated roofing, wall cladding, and temperature-controlled storage spaces, polystyrene panels continue to gain preference. Their balance of performance, cost, and simplicity positions them as a practical solution for developers aiming to enhance building efficiency without increasing operational costs.

By Application

Walls and Floors represented the leading application area for sandwich panels in 2024, capturing 34.6% of total market demand. Their widespread adoption is closely tied to growing interest in energy-efficient, modular, and fast-track construction methods across urban and industrial regions. Sandwich panels in wall systems provide strong insulation, fire resistance, and structural rigidity, making them suitable for both internal partitions and exterior building envelopes. For flooring, they offer high load-bearing strength combined with thermal and acoustic insulation, improving overall building performance.

Commercial buildings, factories, distribution warehouses, and logistics hubs increasingly adopt these panel systems to speed up project timelines and ensure consistent quality. With global construction moving toward prefabrication and sustainability-driven upgrades, the Walls and Floors segment continues to benefit from infrastructure growth, modernization efforts, and rising expectations for high-performance building materials that reduce project delays and enhance lifecycle efficiency.

By End-use

The Non-residential sector accounted for 67.8% of sandwich panel demand in 2024, making it the largest end-use category in the market. This dominance is driven by the rapid development of industrial facilities, logistics hubs, cold storage units, commercial buildings, and healthcare infrastructure—sectors that require durable, fire-resistant, and energy-efficient construction materials. Sandwich panels offer long-term strength, low maintenance, and superior insulation, which help businesses reduce energy consumption and maintain controlled indoor environments. Growth is further reinforced by government investments in industrial parks, public infrastructure, and large-scale commercial development.

As companies prioritize operational efficiency and sustainability targets, sandwich panels remain a preferred solution for creating resilient structures that support temperature regulation, safety compliance, and faster project completion. With expanding global supply chains and increasing demand for modernized facilities, the Non-residential segment continues to serve as the core engine driving the adoption of sandwich panel systems worldwide.

Regional Analysis

Europe leads the Sandwich Panel Market with a 36.80% share valued at USD 5.9 billion, supported by strict energy-efficiency rules, strong renovation activity, and widespread use of prefabricated systems. Its focus on sustainability and advanced construction practices keeps the region at the forefront.

North America remains a steady market, driven by non-residential construction, logistics hubs, and cold storage facilities, backed by mature building technologies and standardized codes. Asia Pacific continues to expand quickly as urbanization, industrial growth, and modular construction accelerate adoption across warehouses, factories, and commercial buildings.

Meanwhile, the Middle East & Africa and Latin America show gradual growth, supported by industrial development, commercial projects, and the increasing need for thermal insulation to improve building performance and speed up construction timelines.

Top Use Cases

- Cold Storage Rooms & Warehouses: Sandwich panels are widely used to build cold storage areas and temperature-controlled warehouses. They keep heat out and cold in, so food, medicine, and other perishable goods stay safe and fresh. These panels also save energy and make buildings work efficiently with less power.

- Industrial & Factory Buildings: Factories and industrial sites often use sandwich panels for walls and roofs because they are strong yet lightweight. They help keep inside temperatures stable, protect equipment, and make buildings last longer. Their quick assembly also speeds up construction.

- Prefabricated & Modular Structures: Sandwich panels are ideal for prefabricated buildings — parts are made in a factory and simply put together on site. This makes building faster, cheaper, and cleaner. They are used in schools, shelters, offices, and temporary rooms.

- Residential Buildings & Homes: In houses, sandwich panels provide thermal insulation to keep rooms warm in winter and cool in summer. Because they are easy to install and resist moisture, they improve comfort and help save on energy bills.

- Clean Rooms & Labs: Clean rooms in labs, hospitals, or electronics factories need controlled air and minimal dust. Sandwich panels help create airtight, insulated walls that maintain clean, steady environments.

- Sound-Controlled Spaces: Sandwich panels can reduce noise when used as internal wall partitions. This makes them useful in places like studios, conference rooms, or busy offices where sound control matters.

Recent Developments

- In January 2025, Isopan entered a joint venture with Marcegaglia Steel, transforming the business structure. This partnership brings together Isopan (part of Manni Group) and Marcegaglia’s production plants to form a stronger company focused on insulated panels (sandwich panels) and related products. It aims to boost production and reach more international markets, becoming one of the largest producers in Europe.

- In February 2024, Metecno Italia (part of the Metecno Group that makes sandwich panels for roofs and walls) received EU, Italian state, and regional funding to install a photovoltaic (solar) system at its factory. This investment is meant to reduce energy use in production and support cleaner, more efficient operations.

Conclusion

The Sandwich Panel Market continues to strengthen as construction shifts toward faster, cleaner, and more efficient building methods. Demand is supported by growing interest in materials that offer insulation, durability, and simplified installation. Industries such as logistics, commercial development, and cold storage increasingly rely on panels to improve building performance and reduce energy use.

Expanding use of modular and prefabricated structures also supports wider adoption across developing and mature economies. With ongoing innovation in eco-friendly insulation and sustainable manufacturing, sandwich panels are becoming an important solution for modern construction needs, helping builders achieve better quality with reduced project time and effort.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)