Table of Contents

Overview

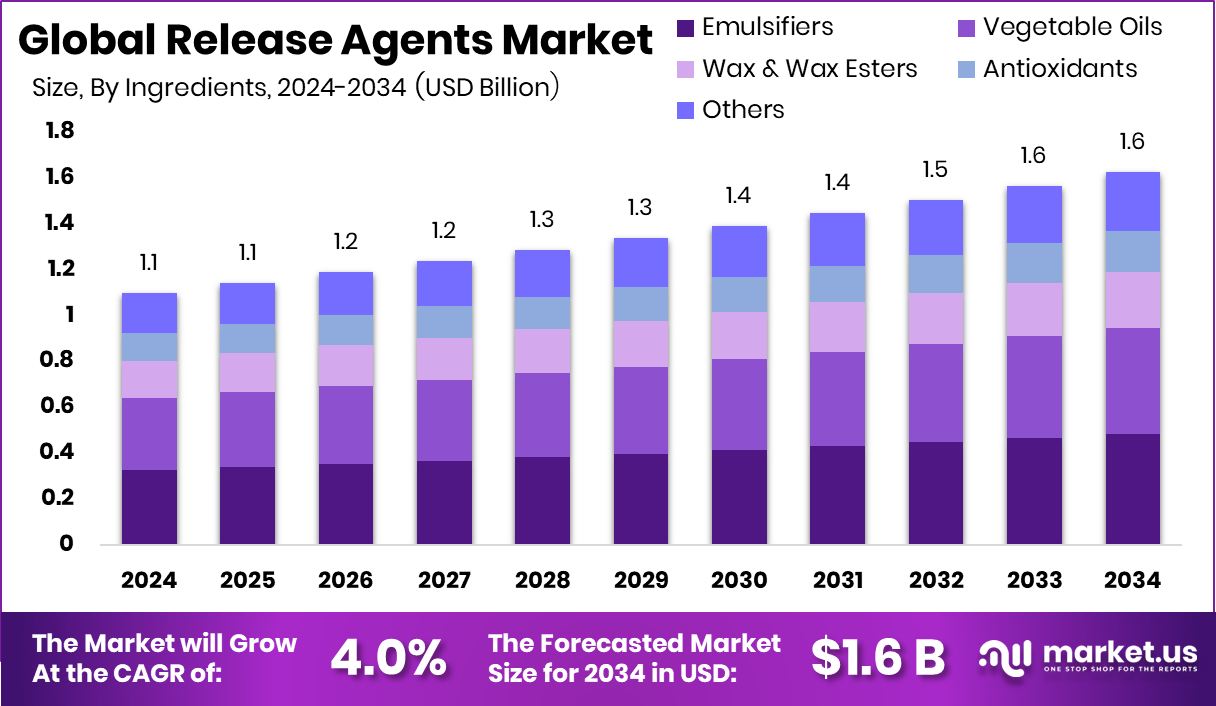

New York, NY – September 26, 2025 – The Global Release Agents Market is projected to reach USD 1.6 billion by 2034, up from USD 1.1 billion in 2024, expanding at a CAGR of 4.0% between 2025 and 2034. North America remains the leading region, holding a 43.9% market share with a value of USD 0.4 billion.

Release agents are specialized substances applied in manufacturing and food processing to prevent products from sticking to molds, pans, or machinery surfaces. By forming a thin protective coating, they allow for easy separation of finished goods without compromising shape, texture, or quality. These agents are widely used across industries such as food and bakery, plastics, rubber, pharmaceuticals, automotive, and construction materials, ensuring smooth production and consistent output.

The market encompasses both edible and non-edible release agents, catering to diverse industrial requirements. In the food sector, rising demand for packaged and ready-to-eat products is driving growth, as release agents help achieve uniform product texture, reduce waste, and maintain hygiene in production lines. Beyond food, their role in large-scale industrial automation is increasingly vital.

As machinery becomes faster and more complex, the need for efficient release agents grows, minimizing downtime, enhancing efficiency, and reducing cleaning efforts. Overall, the release agents market is evolving in response to global trends of sustainability, productivity, and quality assurance, making it a critical enabler in both food processing and industrial manufacturing.

Key Takeaways

- The Global Release Agents Market is expected to be worth around USD 1.6 billion by 2034, up from USD 1.1 billion in 2024, and is projected to grow at a CAGR of 4.0% from 2025 to 2034.

- In the Release Agents Market, emulsifiers account for 29.7%, showing their vital role in production efficiency.

- Liquid form dominates the Release Agents Market with 65.9%, reflecting widespread preference for easy application solutions.

- The bakery sector leads the Release Agents Market applications at 46.8%, driven by high demand for baked goods.

- Independent grocery retailers capture 34.4% sales channel share in the Release Agents Market, emphasizing localized consumer reach.

- The 43.9% market share in North America, worth USD 0.4 Bn, highlights strong demand.

➤ Curious about the content? Explore a sample copy of this report – https://market.us/report/global-release-agents-market/request-sample/

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2024) | USD 1.1 Billion |

| Forecast Revenue (2034) | USD 1.6 Billion |

| CAGR (2025-2034) | 4.0% |

| Segments Covered | By Ingredients (Emulsifiers, Vegetable Oils, Wax and Wax Esters, Antioxidants, Others), By Form (Liquid, Solid), By Application (Bakery, Confectionery, Processed Meat, Convenience Food, Others), By Sales Channel (Independent Grocery Retailer, Direct Sales and Wholesalers, Non-Store Retailers, Others) |

| Competitive Landscape | Archer Daniels Midland Company, AAK Foods, DuPont, IFC Solutions, Inc., Sonneveld Group BV, Puratos Group NV, Lecico GmbH |

➤ Directly purchase a copy of the report – https://market.us/purchase-report/?report_id=157465

Key Market Segments

Ingredients Analysis

In 2024, emulsifiers commanded a leading position in the Ingredients segment of the Release Agents Market, holding a 29.7% share. These agents are critical for delivering non-stick performance, enabling smooth product release, and ensuring consistent quality across food and industrial applications. By forming a uniform film between surfaces and products, emulsifiers minimize waste, boost efficiency, and uphold product integrity.

Their utility extends to industrial applications like rubber and plastics, where precise separation is vital. The rising demand for packaged and ready-to-eat foods has amplified the need for effective emulsifier-based release agents, as manufacturers prioritize clean, cost-efficient, and sustainable solutions. Their compatibility with natural and plant-based formulations further aligns with industry trends toward sustainability and regulatory compliance.

Form Analysis

In 2024, liquid release agents held a commanding 65.9% share in the By Form segment of the Release Agents Market. Their popularity stems from ease of use, excellent coverage, and the ability to create a consistent layer across diverse surfaces.

Liquid agents excel in food processing, bakery, confectionery, plastics, and rubber manufacturing, supporting seamless product release. Compatible with both manual and automated spraying systems, they enhance large-scale operations by reducing downtime and waste.

In food production, liquid release agents ensure hygienic separation, preserving the texture and appearance of baked or molded goods. In industrial settings, they deliver reliable performance across varying temperatures and high-speed production lines. Their cost-effectiveness and efficiency make them the go-to choice for manufacturers seeking to optimize productivity.

Application Analysis

In 2024, the bakery segment dominated the By Application category, capturing a 46.8% share. Release agents are indispensable in bakery operations, ensuring consistent quality and streamlined production for breads, cakes, pastries, biscuits, and confectionery. These agents prevent dough and batter from sticking to pans, molds, or trays, reducing waste, minimizing cleaning time, and boosting productivity.

The segment’s dominance is driven by growing global demand for baked goods, fueled by urban lifestyles, expanding retail bakery chains, and rising consumption of convenient, ready-to-eat products. Health-conscious consumer preferences are also spurring innovation in natural and plant-based release agents, aligning with the demand for cleaner formulations while maintaining product texture and appearance.

Regional Analysis

North America leads with a 43.9% share of the Release Agents Market, valued at USD 0.4 billion.

In 2024, North America held a dominant 43.9% share of the global Release Agents Market, valued at USD 0.4 billion. The region’s leadership is driven by a robust food processing industry, high demand for bakery and confectionery products, and advanced manufacturing practices prioritizing efficiency and quality.

Stringent food safety and hygiene regulations in the U.S. and Canada further boost the adoption of high-quality release agents. Europe follows with a strong industrial base and a focus on sustainable solutions. Asia Pacific is a fast-growing region, propelled by an expanding processed food sector and increasing urban consumption.

Latin America and the Middle East & Africa show steady growth, driven by rising food demand and industrial applications. While emerging regions present growth opportunities, North America remains the primary revenue driver, supported by strong consumer demand, technological advancements, and rigorous quality standards.

Top Use Cases

- Bakery Production: Release agents stop dough and batter from sticking to pans, trays, and molds during baking. This makes it easy to remove fresh bread, cakes, and pastries without damage. They help keep products looking perfect, cut down on waste from ruined batches, and speed up the cleaning of equipment. In busy bakeries, these agents boost daily output and ensure tasty treats come out smooth every time, saving time and effort for bakers everywhere.

- Rubber Manufacturing: In making tires, seals, and gaskets, release agents create a barrier so rubber parts pop out of molds cleanly. They prevent tears or rough spots on the finished items, which is key for safe car parts. Workers apply them to keep machines running fast without stops for stuck pieces. This simple step helps factories make more high-quality rubber goods while keeping costs low and tools in top shape for long runs.

- Plastic Molding: Release agents coat molds to let plastic items like bottles and toys slide out without sticking. They form a thin shield that avoids scratches or defects on the surface. Factories love them for quick cycles in high-speed lines, cutting downtime and scrap. By ensuring even release, these agents help produce clear, strong plastics used in everyday items, making the whole process smoother and more reliable for makers.

- Concrete Forming: Builders use release agents on wooden or metal forms to stop fresh concrete from bonding tightly. Once it hardens, slabs and walls come away easily without cracks or stains. This trick saves hours on cleanup and protects forms for reuse on big projects like bridges. It leads to cleaner sites, faster builds, and better-looking concrete that holds up well, helping teams finish jobs on time and under budget.

- Die Casting for Metals: In forging aluminum or zinc parts for engines and tools, release agents prevent hot metal from welding to dies. They allow quick ejection of shapes like gears without buildup or wear. This keeps production humming at full speed, with fewer rejects and longer die life. Manufacturers rely on them to hit tight deadlines, turning out precise metal pieces that fit perfectly in machines and gadgets.

Recent Developments

1. Archer Daniels Midland Company

ADM is advancing its release agent portfolio by expanding its Nutriance line of non-GMO and clean-label solutions. Recent developments focus on high-stability, low-saturation oil-based systems for bakery and food processing, which enhance shelf life and reduce oil migration. ADM emphasizes sustainability by leveraging its integrated supply chain to provide traceable, plant-derived ingredients that meet consumer demand for simpler formulations.

2. AAK Foods

AAK is innovating with its AAK Crystallization Management approach to create high-performance, palm-free release agents. Recent developments include customized solutions using shea and other specialty fats that provide excellent mold release and anti-sticking properties for complex bakery and confectionery products. AAK focuses on sustainability through its commitment to 100% traceable and segregated palm oil, alongside its pioneering work in alternative oil solutions.

3. Dupont

DuPont recently launched its new DuPont Danisco ONE series, which includes multi-functional release agents combining emulsifiers and hydrocolloids. These innovations help bakers achieve clean label status while ensuring reliable release and improved crumb structure. The development focuses on simplifying ingredient declarations and enhancing processing tolerance, addressing the growing demand for natural and sustainable solutions in industrial baking.

4. IFC Solutions, Inc.

IFC Solutions has developed a new line of high-efficiency, water-based release agents under the “E-Z Release” brand. These products are designed for low-fat applications, reducing consumption and waste while providing superior non-stick performance for meat, dairy, and bakery applications. A key recent focus is on allergen-free and kosher-certified options, catering to specific manufacturer needs for clean-in-place (CIP) systems and food safety.

5. Sonneveld Group BV

Sonneveld is focusing on integrated solutions, combining release agents with other bakery ingredients like mixes and improvers for optimal performance. Recent developments include clean-label, plant-based release agents that are free from silicones and mineral oils. Sonneveld emphasizes application expertise, working closely with customers to develop custom solutions that improve production efficiency and end-product quality, particularly for challenging applications like high-sugar baked goods.

Conclusion

Release Agents as a quiet powerhouse in modern making. They smooth out sticky problems across food, rubber, plastics, and building trades, letting factories churn out goods faster and cleaner. With folks craving quick eats and green ways, these helpers are shifting to plant-based picks that fit eco rules without losing punch. Expect them to grow hand-in-hand with busy lives and smart tech, keeping industries lean, safe, and ahead of the curve in a world that moves quickly.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)