Table of Contents

Overview

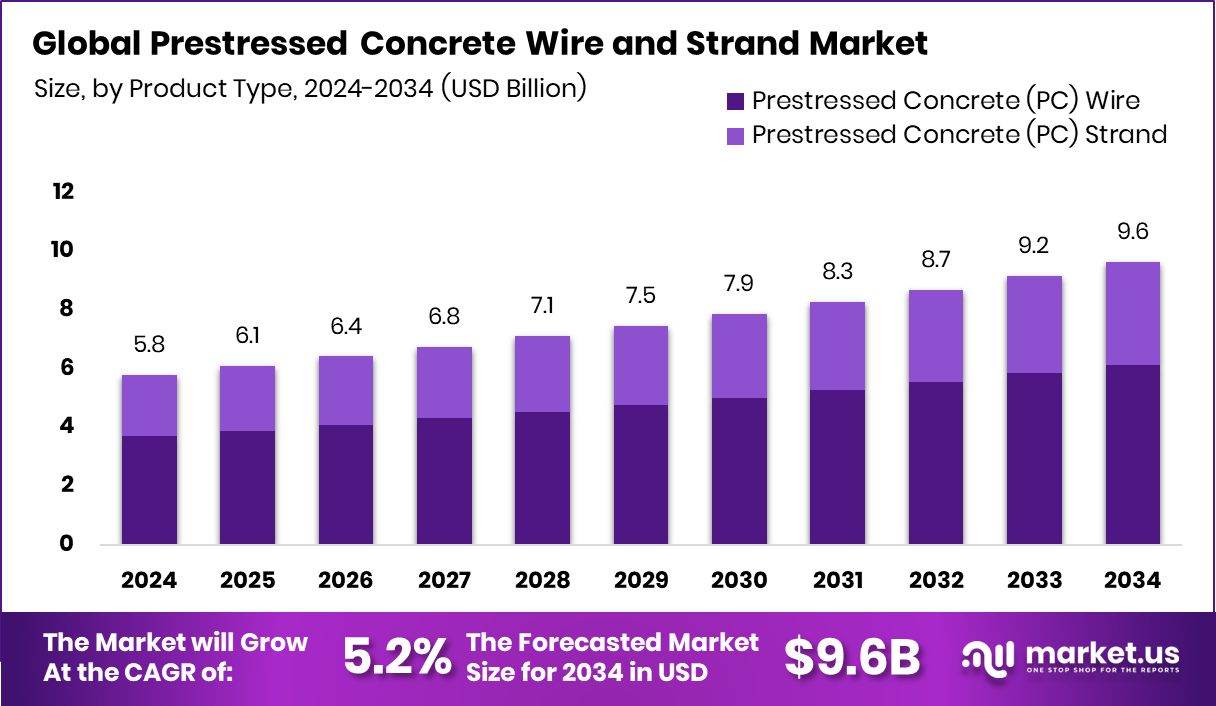

New York, NY – Nov 04, 2025 – The global prestressed concrete wire and strand market is projected to reach USD 9.6 billion by 2034, rising from USD 5.8 billion in 2024 at a CAGR of 5.2% (2025–2034). The Asia Pacific region dominates with a 43.9% share, valued at USD 2.5 billion, driven by rapid infrastructure expansion.

Prestressed concrete wires and strands—high-strength steel materials—are widely used in bridges, railways, tall buildings, and flyovers for durability and load resistance.

In 2024, WeHouse secured ₹25 crore to enhance its tech-driven home construction services across India, reflecting the growing push for modern building systems. The market also benefits from increasing demand for multifamily housing, supported by Dwight’s USD 1 billion fund aimed at large-scale construction projects.

A major opportunity emerges in sustainable infrastructure, as prestressed concrete enables reduced material consumption and extended structure life, aligning with global green-building goals. Companies are also exploring eco-friendly and digital construction tools—highlighted by Lumina’s planned USD 20–40 million Series A round to develop electric construction machinery. These developments illustrate a market shifting toward innovation, sustainability, and technology integration within the global construction ecosystem.

➤ Click the sample report link for complete industry insights: https://market.us/report/global-prestressed-concrete-wire-and-strand-market/request-sample/

Key Takeaways

- The Global Prestressed Concrete Wire and Strand Market is expected to be worth around USD 9.6 billion by 2034, up from USD 5.8 billion in 2024, and is projected to grow at a CAGR of 5.2% from 2025 to 2034.

- Prestressed Concrete Wire holds a 63.8% share, showing its dominance in reinforcement material within construction projects.

- Uncoated strand leads with 41.1%, reflecting high demand for cost-effective solutions in infrastructure works.

- Bridges account for 45.9% market use, highlighting their reliance on strong, durable prestressed reinforcement systems.

- Infrastructure leads end-use with 47.2%, proving prestressed wire and strand are vital for urban development.

- Asia Pacific dominated the Prestressed Concrete Wire and Strand Market with a 43.90% share.

➤ Directly purchase a copy of the report – https://market.us/purchase-report/?report_id=159854

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2024) | USD 5.8 Billion |

| Forecast Revenue (2034) | USD 9.6 Billion |

| CAGR (2025-2034) | 5.2% |

| Segments Covered | By Product Type (Prestressed Concrete (PC) Wire, Prestressed Concrete (PC) Strand), By Coating Type (Uncoated, Galvanized, Epoxy Coated, Others), By Application (Bridges, Buildings, Railway Sleepers, Others), By End-Use (Infrastructure, Construction, Oil and Gas, Power, Others) |

| Competitive Landscape | ArcelorMittal, Bekaert, Fapricela – Fábrica de Produtos de Cimento, S.A., Insteel Industries, Jiangxi Xinhua New Material Co., Ltd., Kataria Group, Kiswire Ltd., N.V. Bekaert S.A., Siam Industrial Wire Co., Ltd., Sumiden Wire Products Corporation |

Key Market Segments

By Product Type Analysis

In 2024, Prestressed Concrete (PC) Wire dominated the By Product Type segment of the Prestressed Concrete Wire and Strand Market, capturing a 63.8% share. This leadership reflects its strong preference for modern construction, driven by its high tensile strength, reliability, and durability. PC wire is extensively applied in bridges, highways, and high-rise buildings, where structural integrity is crucial. Its ability to enhance load-bearing capacity and extend the lifespan of concrete structures positions it as the preferred reinforcement material for engineers and contractors.

The segment’s dominance also mirrors the surge in global infrastructure and urban development projects, where efficiency and long-term performance are key priorities. Overall, PC wire remains the cornerstone of prestressed concrete applications, reinforcing its essential role in supporting the world’s expanding network of durable and sustainable construction projects.

By Coating Type Analysis

In 2024, the Uncoated category dominated the By Coating Type segment of the Prestressed Concrete Wire and Strand Market, holding a 41.1% share. This leadership underscores the continued preference for uncoated products in cost-sensitive, large-scale construction projects where strength, bonding, and efficiency are vital. Uncoated PC wires and strands maintain excellent adhesion with concrete, ensuring reliable performance in bridges, roads, and commercial structures.

Their consistent results and affordability make them the material of choice for many infrastructure developers. The 41.1% share reflects how uncoated products effectively balance durability, tensile strength, and economic value, maintaining their relevance amid advancing construction technologies and growing global infrastructure demands.

By Application Analysis

In 2024, Bridges led the By Application segment of the Prestressed Concrete Wire and Strand Market, commanding a 45.9% share. This dominance highlights the essential role of prestressed materials in bridge construction, where high load-bearing strength, durability, and long-span capability are crucial. Prestressed solutions are widely favored as they minimize maintenance costs and extend the operational lifespan of bridges, offering a sustainable and cost-effective option for large infrastructure projects.

The 45.9% market share underscores their importance in meeting rising transportation and connectivity demands, ensuring safer and more efficient infrastructure in both urban and intercity networks. This leadership reaffirms bridges as the foremost application area driving the growth of prestressed concrete reinforcement worldwide.

By End-Use Analysis

In 2024, the Infrastructure segment dominated the By End-Use category of the Prestressed Concrete Wire and Strand Market, capturing a 47.2% share. This leadership highlights the sector’s growing reliance on prestressed concrete materials for major projects, including highways, rail networks, and public utilities. Such materials provide exceptional durability, load resistance, and cost efficiency, making them indispensable for long-term infrastructure performance.

The 47.2% share reflects the industry’s focus on strengthening global infrastructure to support urbanization, transportation, and connectivity needs. Prestressed concrete wire and strand continue to be the preferred choice in construction due to their ability to reduce maintenance cycles and ensure structural reliability across large-scale public works and national development projects worldwide.

Regional Analysis

In 2024, Asia Pacific led the Prestressed Concrete Wire and Strand Market, commanding a 43.9% share valued at USD 2.5 billion. This dominance stems from massive infrastructure investments in bridges, highways, and urban transport systems, fueled by rapid industrialization and urbanization.

North America and Europe maintained steady growth through renovation and modernization of existing structures, while the Middle East & Africa advanced gradually with government-backed infrastructure programs. Latin America, though smaller, is witnessing steady development in emerging urban areas.

The leadership of Asia Pacific highlights its position as the core hub of global construction expansion, setting trends in technological adoption and sustainable building practices. With nearly half the global market share, the region continues to define the pace of growth, while other regions contribute moderately to the worldwide evolution of prestressed concrete applications.

Top Use Cases

- Long-span Bridges: Prestressed wires/strands are placed under tension inside beams or decks of bridges so the finished concrete can carry heavy loads and span wide gaps without major cracking. This method is especially used for long-span highway and railway bridges.

- High-rise Buildings & Commercial Floors: In multistory buildings, prestressed wire/strand is used in floor slabs and beam elements to allow longer clear spans (fewer columns), thinner slabs, and faster construction. It improves structural strength while reducing material usage.

- Parking Garages / Precast Floor Systems: Precast, prestressed concrete slabs (using these wires/strands) are used in parking structures. They provide high durability, resist deflection under vehicle loads, and enable quick installation of large floor panels.

- Railway Sleepers / Track Infrastructure: Prestressed wires and strands reinforce concrete sleepers (the rectangular ties under rails) so they can handle dynamic rail loads and heavy freight trains with minimal maintenance over time.

- Precast Concrete Elements (Hollow-core Slabs, Beams, Piles): Wires/strands allow precast concrete elements (slabs, beams, piles) to be made lighter yet stronger. For example, hollow-core slabs embed high-tensile strands to reduce weight, improve transport/install ease, and maintain load capacity.

- Marine/Offshore & Retaining Structures: Because prestressed wires provide high tensile strength and better durability, they’re used in structures exposed to harsh environments—like quay walls, sea barriers, embankments, and large retaining walls—where conventional reinforced concrete may degrade faster.

Recent Developments

- In November 2024, Bekaert published an Environmental Product Declaration (EPD) for its low-relaxation PC wire and strand products produced in its Hlohovec (Slovakia) plant. The certificate covers cradle-to-gate life cycle assessment for wire and HDPE-sheathed strand (for corrosion-resistant applications).

- In May 2024, ArcelorMittal’s XCarb® recycled and renewably produced steel fibres won the “Green Award” at the Italian Concrete Technology Awards (ICTA). These steel fibres are used for concrete reinforcement in industrial flooring, precasting, tunnels, and structural elements—relevant to prestressed and reinforced concrete works.

- In April 2024, Fapricela published an Environmental Product Declaration (EPD) for their “Standard PC strand” and “Standard PC wire” – low-relaxation steel products used for prestressed and post-tensioned concrete elements in infrastructures. The EPD (Registration no. EPD-IES-0013304:001) shows Fapricela’s commitment to sustainability and transparency in their prestressing steel offerings.

Conclusion

The Prestressed Concrete Wire and Strand Market continues to grow as global infrastructure development accelerates. These materials play a vital role in strengthening bridges, buildings, rail networks, and other major projects, offering superior durability and performance. With increasing emphasis on sustainability, manufacturers are focusing on energy-efficient production and recyclable materials.

Technological advancements and innovations in high-strength, corrosion-resistant strands are enhancing construction quality worldwide. As urbanization expands and modern construction techniques evolve, the market is set to benefit from steady demand across both developed and emerging regions, reinforcing its importance in shaping resilient and long-lasting infrastructure for the future.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)