Table of Contents

Overview

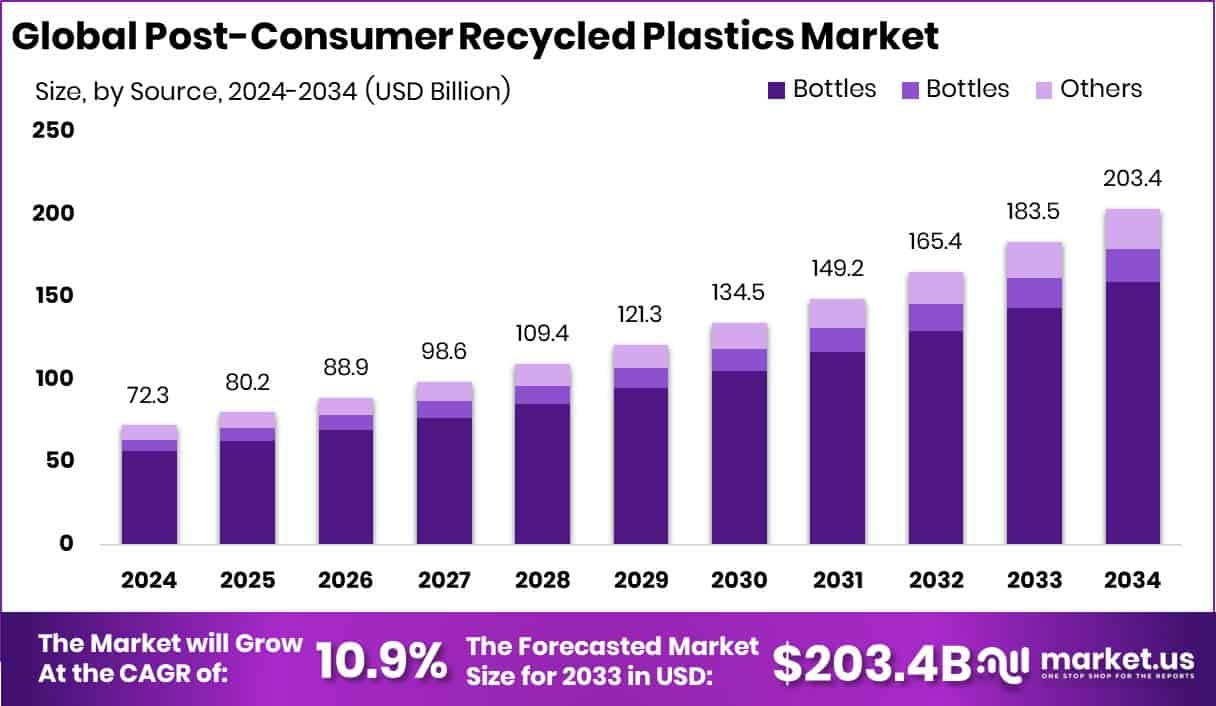

New York, NY – December 05, 2025 – The global post-consumer recycled plastics market is showing strong momentum, supported by regulatory pressure, rising sustainability goals, and growing investments in recycling capacity. The market is projected to grow from USD 72.3 billion in 2024 to nearly USD 203.4 billion by 2034, driven by steady adoption across industries. Asia-Pacific leads this transition, accounting for 44.3% of the market, with recycled plastic growth valued at around USD 32.0 billion, reflecting strong regional sustainability commitments.

Post-consumer recycled plastics are produced from discarded consumer products such as bottles, containers, packaging films, and household plastics. After collection, these materials are sorted, cleaned, and reprocessed into usable raw materials. This process reduces landfill waste, lowers dependence on virgin fossil-based plastics, and supports circular economy practices by keeping materials in use for longer periods.

Demand for recycled plastics is expanding across packaging, consumer goods, textiles, automotive components, and construction materials. Governments are enforcing recycled-content mandates, while companies are shifting toward lower-carbon material choices. Technology improvements in sorting systems, chemical recycling, and waste recovery infrastructure are also accelerating market adoption.

Investment activity is strengthening the market outlook. Polystyvert raised $16 million to advance polystyrene recycling technology, while a Houston-based company secured $12 million in Series A funding to scale a decarbonization-focused recycling plant.

In India, Nayara Energy committed ₹4,000 crore toward a petrochemical project designed to expand circular material capabilities. Additionally, recycling infrastructure has benefited from more than $1 million in grant funding since 2015 through the Foam Recycling Coalition, improving collection and processing efficiency and unlocking long-term growth opportunities.

➤ Click the sample report link for complete industry insights: https://market.us/report/global-post-consumer-recycled-plastics-market/request-sample/

Key Takeaways

- The Global Post-Consumer Recycled Plastics Market is expected to be worth around USD 203.4 billion by 2034, up from USD 72.3 billion in 2024, and is projected to grow at a CAGR of 10.9% from 2025 to 2034.

- In the Post-Consumer Recycled Plastics Market, bottles dominate with 78.2%, driven by packaging recovery systems and growing circular economy commitments.

- Polyethylene (25.4%) leads by type in the Post-Consumer Recycled Plastics Market due to its versatility and wide application use.

- Mechanical recycling holds a 63.9% share in the Post-Consumer Recycled Plastics Market, supported by low processing cost and scalability.

- Asia-Pacific drives the Post-Consumer Recycled Plastics Market with 44.3% and USD 32.0 Bn dominance.

➤ Directly purchase a copy of the report – https://market.us/purchase-report/?report_id=167420

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2024) | USD 72.3 Billion |

| Forecast Revenue (2034) | USD 203.4 Billion |

| CAGR (2025-2034) | 10.9% |

| Segments Covered | By Source (Bottles, Non-bottle Rigid, Others), By Type (Polypropylene (PP), Polystyrene (PS), Polyethylene (PE), Polyvinyl Chloride (PVC), Polyurethane (PUR), Polyethylene Terephthalate (PET), Others), By Recycling Process (Mechanical Recycling, Chemical Recycling, Biological Recycling, Pyrolysis, Others) |

| Competitive Landscape | BASF SE, SABIC, Evonik Industries AG, Sumitomo Chemical Co., Ltd., Arkema, LyondellBasell Industries N.V., Celanese Corporation, Eastman Chemical Company, Chevron Phillips Chemical Company, SUEZ SA, Exxon Mobil Corporation |

Key Market Segments

By Source Analysis

In 2024, bottles dominated the By Source segment of the Post-Consumer Recycled Plastics Market, holding a substantial 78.2% share. This leadership is mainly due to the wide availability of PET and HDPE bottles, which are consistently collected through well-established municipal and commercial recycling systems. Compared with other plastic waste streams, bottles are easier to identify, sort, and process, making them a reliable and cost-effective feedstock for recyclers.

Their stable and high-volume supply enables continuous production of recycled plastic granules that are widely used in packaging, textile fibers, and everyday consumer products. Ongoing investments in recycling infrastructure and increased public participation are further improving bottle collection and recovery rates.

In addition, rising demand for circular packaging solutions and stricter recycled-content regulations across major economies continue to support bottle-based recycling. As a result, bottles are expected to retain their dominant role as the leading source of post-consumer recycled plastics in the coming years.

By Type Analysis

In 2024, Polyethylene (PE) led the By Type segment of the Post-Consumer Recycled Plastics Market, accounting for a 25.4% share. This strong position reflects PE’s extensive use in common packaging materials such as bags, bottles, and films, which create a continuous and highly recoverable waste stream. Its widespread presence in both household and commercial applications ensures reliable feedstock availability for recycling operations.

PE is valued for its flexibility, durability, and ability to retain performance after multiple reprocessing cycles, making it suitable for large-scale recycled applications. These characteristics support its use in packaging, consumer goods, and logistics-related products.

In addition, the growing emphasis on circular packaging models and recycled-content requirements is reinforcing demand for recycled PE. As recycling systems expand and regulations become stricter, PE remains the most scalable and preferred material within the post-consumer recycled plastics market.

By Recycling Process Analysis

In 2024, mechanical recycling dominated the By Recycling Process segment of the Post-Consumer Recycled Plastics Market, holding a 63.9% share. This leadership is mainly attributed to its cost efficiency, well-developed infrastructure, and proven ability to handle large volumes of post-consumer plastic waste. As a mature and widely implemented process, it remains the backbone of global plastic recycling systems.

Mechanical recycling is extensively used to convert sorted plastic waste into recycled pellets that are applied across packaging, construction materials, and various consumer products. Its relatively simple processing steps and lower operational complexity allow faster deployment compared with emerging recycling technologies, making it practical for both municipal and industrial operations.

Growing focus on waste reduction, material recovery, and compliance with recycled-content regulations continues to reinforce the importance of mechanical recycling. As circular economy initiatives expand worldwide, mechanical recycling remains a critical and scalable solution for increasing the post-consumer recycled plastic supply.

Regional Analysis

In 2024, Asia-Pacific led the Post-Consumer Recycled Plastics Market with a 44.3% share, valued at USD 32.0 Bn, supported by strong recycling regulations, a large manufacturing base, and rising use of circular materials in packaging and consumer goods. Improvements in waste collection systems and increasing public awareness have further strengthened the region’s leadership.

North America continues to make steady advances as municipal recycling programs expand and companies increase the use of post-consumer recycled plastics to meet sustainability targets. Europe remains an important market due to stringent environmental policies and broad adoption of recycled materials across packaging and industrial applications.

Latin America is gradually building structured recycling ecosystems, driven by community-led initiatives and improving regulatory support. The Middle East & Africa is at an early development stage, with recycling adoption beginning to grow alongside industrial diversification and emerging sustainability efforts.

Top Use Cases

- Clothing & Textiles: Old plastic bottles (like PET bottles) are cleaned, melted, and spun into fibers — then woven into fabric for clothes, jackets, shoes, and accessories. This helps convert waste into wearable items instead of sending bottles to landfill.

- Reusable Bags & Shopping Bags: Recycled plastics become strong, washable bags that can replace single-use plastic bags. These bags are durable, washable, and help reduce ongoing plastic waste from disposable bags.

- Furniture & Home Goods: Materials from recycled plastic are used to make outdoor furniture, garden benches, decking, tables, and more. These items are weather-resistant and long-lasting — giving waste plastic a “second life” in daily-use products.

- Carpets, Rugs & Home Textiles: Plastic bottles can be transformed into polyester fibers and then into carpets, rugs, mats, or upholstery fabrics. This lets us make home textiles from waste plastic instead of virgin materials.

- Packaging & Containers: Some recycled plastics — especially HDPE — are converted back into new bottles, containers, shampoo/detergent bottles, and other packaging items. This reduces reliance on virgin plastic for everyday packaging needs.

- Construction Materials & Plastic Lumber: Recycled plastics are also used in building materials: plastic lumber, decking, fencing, or even plastic-based boards and structural components. Such materials are often durable, moisture-resistant, and suitable for outdoor and construction uses.

Recent Developments

- In September 2024, Evonik announced a new innovation and growth initiative focused on circular economy solutions. This program bundles its research projects into areas like advanced catalyst-driven recycling, polyurethane/rubber recycling, and other technologies to close material loops

- In March 2024, SABIC signed a Memorandum of Understanding with the Pashupati Group (a major plastic-waste recycler in India) to explore and develop local opportunities for recycling used plastic in India. The plan includes using mechanically and chemically processed waste to feed SABIC’s TRUCIRCLE™ circular-polymer portfolio — aiming to supply recycled-content plastics for packaging and other products.

- In February 2024, BASF started producing “Ccycled®” products in its Port Arthur, Texas, facility, using plastic waste as feedstock rather than fossil raw materials. These recycled-feedstock building blocks go into products like engineered plastics, polyurethanes, and super-absorbent polymers — offering the same performance as conventional materials.

Conclusion

The post-consumer recycled plastics market is becoming a central part of the global shift toward sustainable materials. Growing environmental awareness, stricter waste regulations, and corporate commitments to circular practices are encouraging wider use of recycled plastics across packaging, consumer goods, construction, and automotive applications. Advancements in recycling technologies and improvements in collection systems are leading to better material quality and broader end-use acceptance.

As industries focus on reducing dependence on virgin plastics and improving resource efficiency, post-consumer recycled plastics continue to gain importance. This market supports long-term environmental goals by reducing plastic waste, conserving raw materials, and enabling more responsible production and consumption practices across value chains.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)