Table of Contents

Overview

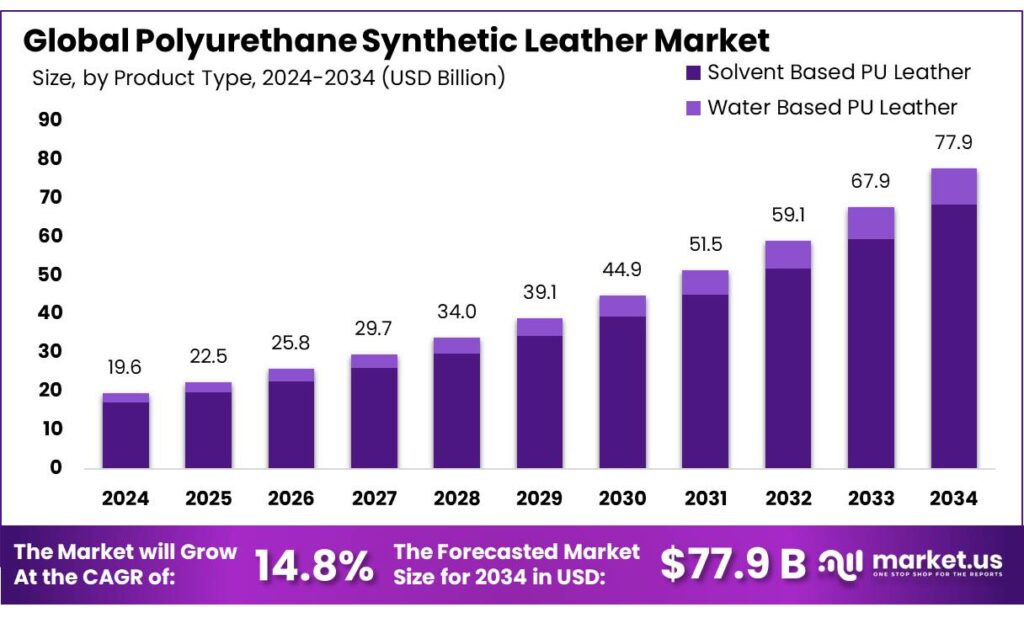

New York, NY – October 01, 2025 – The Global Polyurethane Synthetic Leather Market is projected to reach USD 77.9 Billion by 2034, up from USD 19.6 Billion in 2024, growing at a CAGR of 14.8% between 2025 and 2034. In 2024, the Asia Pacific led the market, accounting for a 38.6% share with revenues of USD 7.5 billion.

Polyurethane (PU) synthetic leather, also called PU faux leather, is engineered to replicate the look and feel of genuine leather. It is manufactured by coating a textile base, such as cotton or polyester, with polyurethane, a durable polymer. Its affordability, cruelty-free nature, and enhanced qualities such as greater durability, softness, and longevity have made it a preferred alternative to traditional PVC-based leather, which was earlier favored in footwear, apparel, and automotive uses.

Recent industry focus has shifted toward bio-based PU synthetic leather, developed as a sustainable option to minimize environmental concerns linked to conventional PU. However, environmental challenges remain a restraint for the sector. According to the American Chemistry Council, polyurethane production across the U.S., Canada, and Mexico totaled 9.1 billion pounds in 2023, underscoring the scale and importance of this material within modern industries.

Key Takeaways

- The Global Polyurethane Synthetic Leather Market was valued at USD 19.6 billion in 2024, at a CAGR of 14.8% and is estimated to reach USD 77.9 billion by 2034.

- Based on product types, solvent-based polyurethane synthetic leather dominated the market in 2024, comprising about 87.8% share of the total global market.

- Among the applications of polyurethane synthetic leather is widely used in the footwear industry, and hence it dominated the market in 2024, accounting for around 34.5% of the market share.

- Asia Pacific was the largest market for polyurethane synthetic leather in 2024, with approximately 38.6% share of the total global market.

➤ Curious about the content? Explore a sample copy of this report – https://market.us/report/polyurethane-synthetic-leather-market/request-sample/

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2024) | USD 19.6 Billion |

| Forecast Revenue (2034) | USD 77.9 Billion |

| CAGR (2025-2034) | 14.8% |

| Segments Covered | By Product Type (Water-Based PU Leather, Solvent-Based PU Leather), By Applications (Automotive, Footwear, Furniture, Apparel, Other Applications) |

| Competitive Landscape | Kuraray Co., Ltd., San Fang Chemical Industrial Co., Ltd., Asahi Kasei Corporation, Teijin Limited, Mayur Uniquoters Ltd., Nan Ya Plastics Corp., Alfatex Italia SRL, Huafeng Group, FILWEL Co., Ltd., Yantai, Wanhua Synthetic Leather Group Co., Ltd., Zhejiang Hexin Science and Technology Co., Ltd., Evonik Industries AG, DIC Corporation, Other Key Players. |

➤ Directly purchase a copy of the report – https://market.us/purchase-report/?report_id=157539

Key Market Segments

Product Type Analysis

The polyurethane synthetic leather market is divided into water-based and solvent-based PU leather. In 2024, solvent-based PU leather led with an 87.8% market share due to its cost-effective production and close resemblance to genuine leather in texture and appearance. Its well-established manufacturing process further supports its dominance. However, solvent-based PU leather uses harmful organic solvents like dimethylformamide, contributing to pollution and health risks.

In contrast, water-based PU leather is gaining popularity due to its eco-friendly profile, using water as a solvent to significantly reduce volatile organic compound (VOC) emissions and pollutants. Stricter environmental regulations and rising demand for sustainable products are expected to drive water-based PU leather to overtake solvent-based production in the future, despite the latter’s current prevalence due to cost and technological advantages.

Application Analysis

In 2024, footwear dominated the polyurethane synthetic leather market, accounting for 34.5% of global consumption. PU leather’s durability, flexibility, lightweight nature, and high abrasion and tear resistance make it ideal for footwear, meeting the industry’s need for performance and affordability. It serves as a cost-effective alternative to natural leather, offering diverse colors and textures that align with the demands of fast fashion and e-commerce for stylish, budget-friendly shoes.

The apparel sector ranks as the third-largest application, valued for PU leather’s affordability, water resistance, ease of cleaning, and variety of colors and textures, making it suitable for products like jackets and bags. Additionally, the automotive industry increasingly utilizes PU synthetic leather for its durability, flame retardance, and stain resistance, meeting the rising performance standards for vehicle interiors.

Regional Analysis

In 2024, the Asia-Pacific region led the global polyurethane synthetic leather market, holding a 38.6% revenue share and a market value of approximately USD 7.5 billion. This dominance is driven by the region’s cost-effective production, versatile applications, and extensive manufacturing infrastructure. Countries like China and India, with China as the world’s top producer and exporter of faux leather, benefit from large-scale production capabilities and high demand from cost-conscious markets, solidifying Asia-Pacific’s position as the market leader.

Top Use Cases

- Footwear Production: Polyurethane synthetic leather shines in making shoes because it mixes toughness, bendiness, and lightness perfectly. It stands up to daily scrapes and tears better than many fake options, while keeping feet comfy. Makers love its low price tag as a stand-in for real leather, letting them play with colors and patterns to match quick style shifts and online shopping booms. This makes trendy, wallet-friendly kicks a go-to for everyone.

- Apparel Manufacturing: In clothes like jackets and bags, this fake leather wins for being cheap, strong, and easy to wipe clean. It shrugs off water and comes in endless shades and feels, opening up fun designs without the high cost of true hide. Shoppers grab it for everyday gear that looks sharp but handles rough use, fitting the push for reachable fashion that doesn’t harm animals or the planet.

- Automotive Interiors: Car makers turn to polyurethane synthetic leather for seats, dashes, and panels since it fights stains, flames, and wear like a champ. Its soft touch and custom looks boost ride comfort without sticking or fading fast. As folks want greener rides, this stuff steps up as a smart swap for real leather, keeping costs down while meeting tough safety rules in busy vehicle builds.

- Furniture Upholstery: Sofas and chairs wrapped in this synthetic leather stay fresh longer thanks to its spill-proof and scratch-resistant vibe. It’s lighter and simpler to care for than genuine stuff, suiting homes that need style on a budget. Designers mix in wild textures and hues to freshen up spaces, riding the wave of easy-living setups that skip animal products for planet-friendly flair.

- Fashion Accessories: Wallets, purses, and belts crafted from polyurethane synthetic leather pop with their sleek mimic of real hide at a fraction of the cost. It’s flexible for shaping into slim, tough items that resist daily bangs and moisture. Brands push it for quick-turn trendy bits that appeal to eco-aware crowds, blending vegan ethics with versatile, eye-catching options for on-the-go lives.

Recent Developments

1. Kuraray Co., Ltd.

Kuraray is advancing its “Clarino” brand PU leather with a focus on high functionality and sustainability. Recent developments include materials with enhanced anti-viral properties and new series made with bio-based or recycled raw materials. The company is targeting applications in sports footwear, interior design, and automotive interiors, emphasizing durability and a reduced environmental footprint through its proprietary manufacturing processes.

2. San Fang Chemical Industrial Co., Ltd.

San Fang Chemical (SFCC) is aggressively expanding its eco-friendly “Sofrina” PU synthetic leather line. Recent initiatives involve increasing the production of products meeting international sustainability standards, such as Bluesign certification. They are developing high-performance, bio-based PU materials for global brands in the apparel, footwear, and accessories sectors, focusing on reducing volatile organic compound (VOC) emissions and incorporating recycled polyester.

3. Asahi Kasei Corporation

Asahi Kasei’s recent developments for its “Lamous” PU synthetic leather focus on the automotive market. They have introduced new grades with advanced design capabilities, such as deep embossing and premium aesthetics, alongside high physical properties for durability. A key innovation is the creation of lighter-weight materials that contribute to vehicle fuel efficiency. The company also emphasizes materials with low VOC emissions for improved cabin air quality.

4. Teijin Limited

Teijin is leveraging its “Ecopia” bio-based PU resin to develop sustainable synthetic leathers. A key recent development is the expansion of its “SOLOTEX” series, which offers a soft, suede-like texture with excellent colorfastness and abrasion resistance, targeting the sports shoe and bag markets. Teijin is also promoting closed-loop recycling initiatives, aiming to reclaim and reuse materials from post-industrial waste in its production processes.

5. Mayur Uniquoters Ltd.

As a key supplier to the automotive industry, Mayur’s recent developments focus on expanding its production capacity and product range for PU leather. The company is investing in new machinery and technology to manufacture advanced, printed, and embossed materials for car interiors. A significant focus is on developing finer, softer finishes to meet the evolving demands of global automotive OEMs for premium and mid-segment vehicles.

Conclusion

Polyurethane Synthetic Leather is a rising star in the materials world, blending smart design with green smarts to shake up old ways. It steps in where real leather falls short on cost and kindness to animals, offering a fresh path for makers in fashion, rides, and home gear. With folks leaning harder into sustainable picks and rules tightening on waste, this versatile stuff is set to grow its spot, sparking fresh ideas that keep things affordable and earth-friendly. Expect more tweaks to make it even tougher and kinder to the air, pulling in brands eager to lead the charge toward a cooler, cruelty-free tomorrow.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)