Table of Contents

Overview

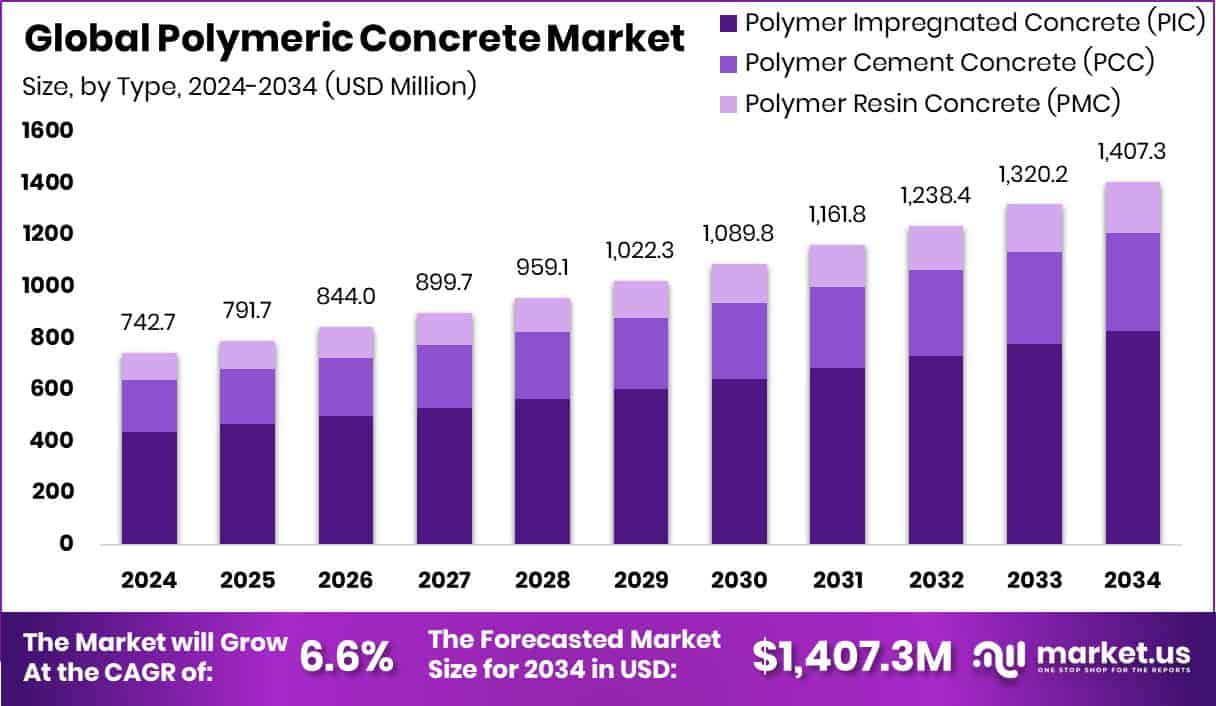

New York, NY – August 08, 2025 – The global polymeric concrete market is projected to grow significantly, reaching USD 1,407.3 million by 2034 from USD 742.7 million in 2024, driven by a compound annual growth rate (CAGR) of 6.6% between 2025 and 2034. North America currently leads the market with a 43.2% share, equivalent to USD 320.8 million in 2024.

Polymeric concrete, which uses polymer compounds instead of cement as a binder, is gaining traction due to its superior performance characteristics such as higher tensile strength, better durability, and increased resistance to water, chemicals, and environmental wear compared to traditional concrete.

This advanced material is widely applied in various construction scenarios, including new infrastructure development, structural repairs, and use in demanding environments such as marine structures, chemical plants, and heavy industrial zones. The rising need for construction solutions that offer longer life cycles and reduced maintenance has accelerated the adoption of polymeric concrete. Its flexibility in use being suitable for both precast and cast-in-place applications further enhances its appeal, allowing it to meet diverse engineering and architectural needs.

The shift in the construction industry toward more robust and low-maintenance materials is further supported by government initiatives. Notably, the U.S. Federal Highway Administration (FHWA) has championed the use of polymer-based materials through programs like the “Innovative Bridge Research and Construction” initiative, which promotes the use of polymeric concrete to extend the life and improve the performance of bridges. Additionally, the expected growth in the ready mix concrete (RMC) sector, projected to account for 20–25% of domestic cement demand in the near future, is likely to further stimulate demand for advanced admixtures and polymer-enhanced building materials.

Key Takeaways

- The global polymeric concrete market is projected to reach USD 1,407.3 million by 2034, rising from USD 742.7 million in 2024, with a steady CAGR of 6.6% during 2025–2034.

- Polymer Impregnated Concrete (PIC) leads the product segment, accounting for 59.3% of the market, thanks to its exceptional durability.

- Epoxy-based polymeric concrete makes up 37.7% of the market, widely preferred for its excellent adhesive strength.

- Flooring blocks represent 28.5% of total applications, gaining popularity for their long-lasting performance and toughness.

- The industrial sector remains the dominant end-use area, using 34.6% of polymeric concrete, particularly for infrastructure development.

- North America holds a commanding 43.2% market share, valued at USD 320.8 million, driven by robust infrastructure investment.

➤ For a deeper understanding, click on the sample report link: https://market.us/report/polymeric-concrete-market/free-sample/

Report Scope

| Market Value (2024) | USD 742.7 Million |

| Forecast Revenue (2034) | USD 1,407.3 Million |

| CAGR (2025-2034) | 6.6% |

| Segments Covered | By Type (Polymer Impregnated Concrete (PIC), Polymer Cement Concrete (PCC), Polymer Resin Concrete (PMC)), By Polymer Type (Epoxy, Polyester, Furan, Vinylester, Latex, Acrylate, Methyl Methacrylate, Others), By Application (Flooring Blocks, Facade and Curtain Wall, Pump Bases, Chemical Containments, Waste Containers, Trench Drains, Others), By End-use (Industrial, Municipal, Residential, Commercial, Infrastructure) |

| Competitive Landscape | Interplastic Corporation, ULMA Architectural Solutions, BASF SE, ACO FUNKI A/S, Polycare Namibia, Sika AG, Dudick Inc., Forté Composites, Kwik Bond Polymers, Lidco Building Technologies, ErgonArmor, TPP Manufacturing Sdn. Bhd, Carborundum Universal Limited, ACO, MEA Group, Other Key Players |

➤ Directly purchase a copy of the report – https://market.us/purchase-report/?report_id=146620

Key Market Segments

1. By Type Analysis

- In 2024, Polymer Impregnated Concrete (PIC) led the market by type, holding a 59.3% share, thanks to its superior mechanical strength, low permeability, and enhanced durability. Its widespread use in civil infrastructure like bridges, tunnels, and industrial flooring is due to its excellent resistance to moisture and chemical corrosion, making it ideal for harsh environments. The material’s compatibility with precast applications and ease of use has reduced long-term maintenance costs, while growing infrastructure investments, particularly in industrial regions, continue to drive its adoption.

2. By Polymer Type Analysis

- Epoxy emerged as the dominant polymer type in 2024 with a 37.7% market share, primarily due to its outstanding bonding strength, chemical resistance, and durability under extreme conditions. Its application in high-stress environments such as industrial floors and precast elements is supported by its reduced shrinkage and strong adhesion. Additionally, epoxy’s fast curing time and versatility with different aggregates make it a preferred choice for time-sensitive construction and repair projects in industrial and commercial sectors.

3. By Application Analysis

- Flooring blocks accounted for 28.5% of the market in 2024, driven by the increasing need for high-strength, chemical-resistant flooring in industrial and commercial spaces. Known for their load-bearing capacity, abrasion resistance, and minimal maintenance, these blocks are ideal for facilities like manufacturing plants and chemical units. Their quick installation and ability to endure thermal shocks and aggressive cleaning processes have made them a cost-efficient solution for demanding operational environments.

4. By End-use Analysis

- The industrial sector led the polymeric concrete market by end-use in 2024, capturing a 34.6% share, due to rising demand for durable and corrosion-resistant materials across manufacturing, chemical, and wastewater treatment facilities. Polymeric concrete’s strength, chemical stability, and low maintenance needs have made it suitable for applications such as drainage systems, flooring, and containment structures. Its ease of installation and minimal downtime during repairs support operational efficiency, aligning with industry goals of sustainability, safety, and long-term performance.

Regional Analysis

- One of the primary challenges facing the polymeric concrete market is its high upfront cost. The materials used such as specialized resins and additives are significantly more expensive than those in traditional cement-based concrete, making it a less attractive option for many construction companies, particularly in budget-conscious projects or developing regions.

- While polymeric concrete offers long-term advantages like superior durability and lower maintenance needs, the initial investment often becomes a barrier to adoption. This issue is especially critical in public infrastructure projects, where tight budgets restrict the use of higher-cost alternatives.

- Additionally, the need for skilled labor to properly mix and apply polymer-based concrete adds to overall project expenses. These financial concerns have slowed its adoption in large-scale construction efforts and continue to be a significant hurdle for broader market growth.

Top Use Cases

- Containment Structures: Polymeric concrete is ideal for constructing chemical containment areas in industrial plants and wastewater facilities. Its excellent chemical resistance and low permeability help ensure leaks are prevented. This material extends the life of containment installations while reducing maintenance and repair costs over time.

- Pump Bases & Equipment Foundations: Used for pump bases in water treatment or chemical plants, polymeric concrete offers high mechanical strength and vibration damping. Its durability under heavy load and exposure to corrosive fluids supports long-lasting, stable installations. Equipment retains alignment and efficiency, with less need for frequent repairs or leveling.

- Flooring Blocks for Industrial Facilities: Industrial and commercial spaces use polymeric concrete flooring blocks for heavy-duty flooring that resists abrasion, chemicals, moisture, and thermal shock. These seamless blocks are quick to install, low-maintenance, and ideal where hygiene and durability matter like factories, warehouses, or chemical processing units.

- Trench Drains & Drainage Applications: Polymeric concrete is frequently chosen for trench drains in infrastructure and industrial sites. It handles heavy weight loads, resists chemicals and moisture, and remains robust even in harsh environments. Its long service life means fewer replacements and minimal downtime for drainage systems.

- Bridge Deck Overlays & Infrastructure Rehabilitation: In bridge repair and highway overlays, polymeric concrete is applied to protect existing structures from wear, corrosion, and freeze-thaw damage. Its strong bonding and quick curing make it suitable for fast restoration work in aging infrastructure, offering extended life and minimal traffic disruption.

- Precast Architectural & Structural Components: Precast elements such as wall panels, utility pits, and architectural cladding use polymeric concrete for design flexibility and high performance. These components benefit from molded precision, low permeability, and enhanced durability providing both functional and aesthetic advantages in modern construction.

Recent Developments

1. Sika AG:

- In April 2024, Sika AG completed the acquisition of Kwik Bond Polymers (KBP), a U.S. based manufacturer specializing in polymer systems for bridge deck and concrete infrastructure refurbishment. KBP’s products including polyester‑based overlay mixes and methacrylate sealers enhance durability and extend service life of bridges and heavy infrastructure. The acquisition expands Sika’s infrastructure portfolio, helps reduce carbon footprint, and improves supply chain reach through KBP’s production facilities in California and Pennsylvania.

2. Interplastic Corporation:

- Interplastic Corporation continues to develop polymer concrete formulations using unsaturated polyester resins designed for fast‑cure, low‑shrinkage applications. Their SIL07BA‑1069 and SIL07BA‑2287 products support high filler loading and quick strength gain, ideal for sub‑floors, ramps, docks, and parking structures. Recent company updates emphasize enhanced room‑temperature curing and improved viscosity control to increase on‑site productivity and reduce cracking risk in polymer concrete applications.

3. ULMA Architectural Solutions:

- As of May 2025, ULMA Architectural Solutions enhanced its drainage product line with the KOMPAQDRAIN® system a polymer concrete channel featuring a built-in slope for better hydraulic performance in civil works. The company also launched updated Environmental Product Declarations (EPDs) and showcased its polymeric solutions at major trade fairs. ULMA continues to expand its polymer concrete offerings for façade, precast, and drainage applications across global infrastructure projects.

4. ErgonArmor (Ergon Companies):

- ErgonArmor supports industrial infrastructure with polymer concrete products like TUFCHEM™ Epoxy Polymer Concrete, engineered for deep pours with low heat generation and high chemical resistance. This 3-component system allows flexible placement in trenches, machine bases, or utility vaults. Its low shrinkage, adjustable slump, and broad chemical resistance make it suited for harsh industrial environments and rapid repairs in containment and flooring applications.

Conclusion

The polymeric concrete market is steadily gaining momentum, driven by its superior strength, durability, and chemical resistance compared to traditional concrete. With increasing demand for long-lasting infrastructure solutions in industrial, civil, and commercial construction, this material is proving its value despite its higher initial cost. Companies like Sika AG, BASF, ULMA, and ErgonArmor are actively expanding product lines and acquiring firms to improve polymeric concrete applications, including bridge overlays, flooring, drainage, and containment systems. As sustainability, longevity, and fast installation become more critical, polymeric concrete is positioned to play a larger role in infrastructure upgrades across North America, Europe, and Asia in the years ahead.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)