Table of Contents

Overview

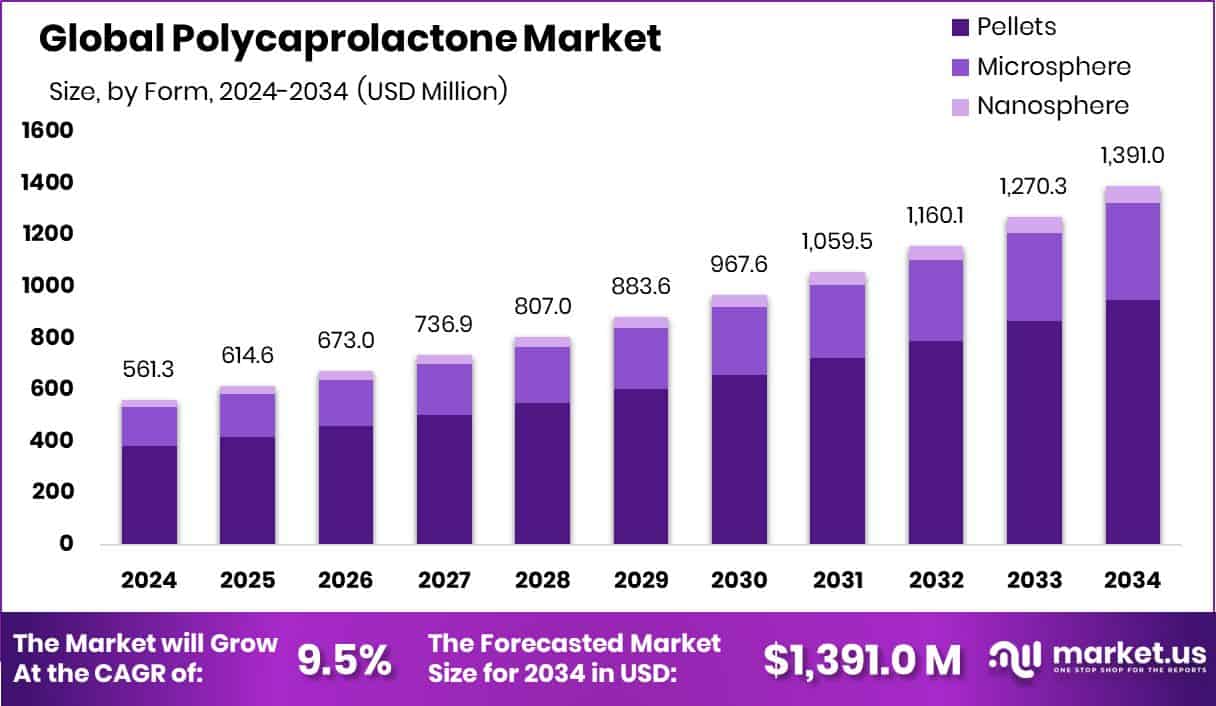

New York, NY – August 07, 2025 – The global polycaprolactone market is projected to grow significantly, reaching a value of USD 1,391.0 million by 2034 from USD 561.3 million in 2024, at a CAGR of 9.5% between 2025 and 2034. North America currently leads the market with a 39.20% share, driven by strong demand for biodegradable materials in both medical and industrial sectors. PCL, a biodegradable polyester with a low melting point of around 60°C, is valued for its flexibility, biocompatibility, and slow degradation rate making it ideal for various medical applications such as sutures, tissue engineering, and drug delivery systems.

The polycaprolactone market includes a wide range of industries, from healthcare and agriculture to construction and packaging. It encompasses the entire supply chain, from raw material providers to chemical processors and end-users. The market is increasingly influenced by innovations in sustainable materials, growing environmental awareness, and favorable regulations promoting biodegradable plastics. PCL’s ease of processing also supports its application in 3D printing, coatings, and various packaging solutions.

Market growth is largely fueled by the healthcare sector, where PCL is in demand for use in bioresorbable implants, tissue scaffolds, and extended drug-release systems. Rising surgical procedures and the need for biocompatible, long lasting materials are accelerating its use. Additionally, the growing consumer shift toward eco-friendly and compostable packaging is further supporting demand, reinforcing PCL’s importance as a sustainable alternative to traditional, petroleum-based plastics.

Key Takeaways

- The global polycaprolactone market is forecasted to grow from USD 561.3 million in 2024 to around USD 1,391.0 million by 2034, registering a CAGR of 9.5% between 2025 and 2034.

- Polycaprolactone in pellet form accounts for the largest market share at 68.2%, thanks to its ease of handling and processing.

- High molecular weight PCL holds a dominant 67.7% share due to its superior mechanical strength and performance characteristics.

- Thermoplastic polyurethane (TPU) applications represent 36.1% of the market, reflecting rising demand for flexible and durable materials.

- The healthcare industry leads in end-use, capturing 43.8% of the market, driven by increased use of PCL in biomedical devices and drug delivery systems.

- North America reached an estimated market value of USD 220.0 million in 2024, fueled by high demand in medical and biodegradable industrial applications.

➤ For a deeper understanding, click on the sample report link: https://market.us/report/global-polycaprolactone-market/free-sample/

Report Scope

| Market Value (2024) | USD 561.3 Million |

| Forecast Revenue (2034) | USD 1,391.0 Million |

| CAGR (2025-2034) | 9.5% |

| Segments Covered | By Form (Pellets, Microsphere, Nanosphere), By Molecular Weight (High Molecular Weight, Low Molecular Weight), By Application (Thermoplastic Polyurethane (TPU), Adhesives, Films and Coatings, Drug Delivery, Sutures, Tissue Engineering, 3D Printing), By End-use (Healthcare, Packaging, Agriculture, Construction, Automotive, Consumer Goods, Others) |

| Competitive Landscape | BASF SE, ChemPoint, Corbion, Daicel Corporation, Durect Corporation, EsunIndustrial Co., Ltd, eSUNMed Biotechnology (Shenzhen) Co.,Ltd, Haihang Group, Hunan Juren Chemical Hitechnology Co.,Ltd, JenKem Technology, Kashima Polymers Corporation, BASF, Perstorp Holding AB, Polymer Source, Inc., Polysciences, Inc., Shenzhen Esun Industrial Co., Ltd, Shenzhen Polymtek Biomaterial Co., Ltd, SK Functional Polymer, Spectrum Chemical, Unilong Industry Co., Ltd., VIZAG Chemicals |

➤ Directly purchase a copy of the report – https://market.us/purchase-report/?report_id=153390

Key Market Segments

1. By Form Analysis

- In 2024, polycaprolactone in pellet form led the market with a 68.2% share, driven by its ease of processing, uniform melting behavior, and compatibility with large scale manufacturing techniques. Pellets are ideal for extrusion and injection molding, particularly in medical, packaging, and additive manufacturing sectors, due to their reliability, storage stability, and ability to maintain consistent product quality during production.

2. By Molecular Weight Analysis

- High molecular weight polycaprolactone dominated the market with a 67.7% share in 2024, owing to its excellent mechanical strength, thermal stability, and extended degradation time. These properties make it well suited for use in biomedical implants, tissue engineering, and durable components in 3D printing, especially where long-term performance and precision are critical.

3. By Application Analysis

- Thermoplastic polyurethane (TPU) applications held a leading 36.1% share in 2024, benefiting from polycaprolactone’s flexibility, biodegradability, and processability. PCL enhances TPU’s softness, elasticity, and environmental profile, making it ideal for flexible films, footwear soles, molded goods, and cable insulation offering a sustainable alternative to traditional plastic materials.

4. By End-use Analysis

- The healthcare sector captured 43.8% of the market in 2024, largely due to increasing use of polycaprolactone in medical applications like sutures, drug delivery systems, wound care, and tissue scaffolds. Its slow, controlled biodegradation and biocompatibility make it ideal for long term use inside the human body, supporting its expanding role in surgical and regenerative medicine solutions.

Regional Analysis

- In 2024, North America led the global polycaprolactone market, accounting for a 39.20% share and a market value of approximately USD 220.0 million. This dominance is largely attributed to the region’s strong demand for biodegradable materials in healthcare, including applications such as drug delivery systems, tissue scaffolds, and medical implants. The region’s advanced medical infrastructure and early adoption of biocompatible technologies have further reinforced its leadership position.

- Europe followed with steady market growth, driven by strict environmental policies and a growing commitment to sustainable material adoption across industries. The region’s focus on reducing plastic waste and promoting eco friendly alternatives has increased interest in polycaprolactone, especially in sectors like packaging and biomedical applications. Meanwhile, the Asia Pacific region is emerging as a significant growth area due to industrial expansion, rising environmental awareness, and growing demand for bio based polymers in countries such as China and India.

- Latin America and the Middle East & Africa showed gradual progress in 2024, with increasing application of biodegradable materials in specific industries. However, North America remains the primary contributor to global market revenue, supported by strong innovation in medical technology and a robust industrial base. As global demand for high performance, bioresorbable materials continues to rise, North America’s influence on the market is expected to remain substantial.

Top Use Cases

- 3D‑Printed Biomedical Scaffolds: PCL is increasingly used in 3D bioprinting to create intricate tissue scaffolds and bone implants. Its low melting point, biocompatibility, and slow degradation rate make it ideal for personalized patient specific constructs. Researchers and biotech firms incorporate PCL based bio‑inks to support tissue engineering and regenerative medicine applications.

- Controlled Drug Delivery Systems: PCL’s slow biodegradation and compatibility with active molecules make it a prime material for long‑term drug release devices. It is used in medical implants and microspheres to deliver medication gradually, reducing dosing frequency and improving therapeutic outcomes in chronic treatment scenarios.

- Thermoplastic Polyurethane Enhancement: When blended into TPU, PCL boosts flexibility, elasticity, and biodegradability ideal for flexible films, footwear soles, and cables. This combination balances performance and eco-friendliness, meeting growing demand for sustainable materials in consumer goods and industrial applications.

- Biodegradable Packaging Materials: PCL is used to produce compostable films and containers, either alone or blended with starch or other biopolymers. Its mechanical strength and biodegradability meet environmental regulations and consumer demand, positioning it as a greener alternative to traditional plastics in packaging.

- Medical Implant and Wound Dressing Innovation: With its high biocompatibility and predictable degradation inside the body, PCL is used for bioresorbable sutures, tissue engineering scaffolds, and wound dressings. It supports healing without requiring removal, adding medical convenience while aligning with sustainability trends in healthcare.

Recent Developments

1. BASF SE

- In March 2024, BASF announced a price increase of USD 0.10 per pound (≈ USD 220/tonne) for its Capromer polycaprolactone and epsilon caprolactone grades in North and South America, reflecting market adjustments and supply chain costs. Additionally, BASF expanded its Capromer PD1‑10 and PD1‑20 PCL-based polyester polyols for use in TPU elastomers, adhesives, coatings, and reactive diluents, emphasizing their hydrolytic stability, low‑temperature flexibility, and weather resistance. These developments reinforce BASF’s commitment to advanced PCL applications in high-performance polyurethane systems.

2. Corbion

- Corbion continues to offer PURASORB bioresorbable polymers, which include formulations based on caprolactone monomers tailored for controlled drug delivery systems and resorbable medical implants. Their GMP grade block copolymers support long term release profiles and high biocompatibility for pharmaceutical and tissue engineering applications. Corbion’s focus on PCL integration with lactide and glycolide in the PURASORB line supports innovation in regenerative medicine and implantable device design. These developments underscore Corbion’s role in delivering compliant and customizable PCL based biomaterials for healthcare clients.

3. Perstorp Holding AB

- Perstorp has introduced a new high performance PCL grade specifically engineered for biomedical uses, offering enhanced mechanical properties and controlled degradation behavior. It aims to support advanced medical device applications including tissue scaffolds and long‑term drug delivery implants. This specialized PCL grade addresses reliability, safety, and custom formulation needs in regulated healthcare markets, positioning Perstorp as a targeted innovator in sustainable polymer solutions for bioresorbable applications.

4. Daicel Corporation

- In May 2024, Daicel inaugurated a state of the art Technical Solutions Innovation Center in Farmington Hills, Michigan, to bolster its caprolactone and derivative business. As part of a strategic collaboration with Gantrade, Daicel launched novel blends combining PTMEG polyols with caprolactone based polyols. These products enhance polyurethane performance across wider temperature ranges, improve flex fatigue life, boost tensile strength, and minimize cold hardening effects in elastomers.

5. Shenzhen eSUN Industrial Co., Ltd.

- Shenzhen eSUN, recognized as a major player in 3D printing and specialty polymers, continues expanding its polycaprolactone portfolio particularly PCL diols used in additive manufacturing and biodegradable TPU blends. Benefiting from solid R&D investment and production scale up, eSUN has increased commercial supply for medical grade PCL filaments and flexible PCL‑TPU materials tailored for printing applications. Its momentum is supported by accelerated demand for eco‑friendly printing polymers.

Conclusion

The polycaprolactone market is showing strong growth due to its rising demand in biodegradable and medical grade applications. As industries continue moving toward sustainable and environmentally friendly materials, PCL stands out because of its flexibility, safe degradation, and compatibility with human tissues. Its growing use in drug delivery systems, tissue engineering, and 3D printing reflects its adaptability across sectors. Companies in this space are innovating to improve PCL’s performance and processing characteristics, especially for use in medical, packaging, and industrial products. With increasing awareness about environmental protection and a push for alternatives to petroleum based plastics, the polycaprolactone market is expected to maintain its upward trend.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)