Table of Contents

Introduction

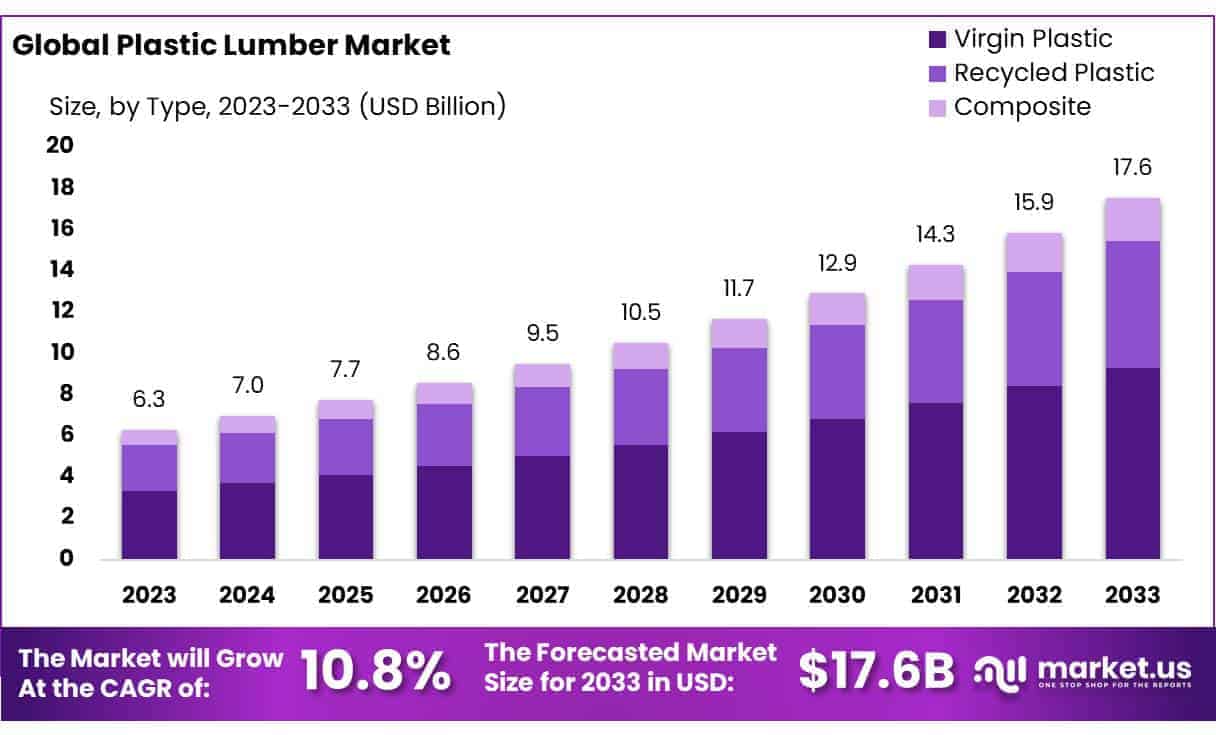

The global Plastic Lumber Market is experiencing significant growth, driven by increasing environmental awareness, advancements in recycling technologies, and the rising demand for sustainable building materials. The market size is expected to reach approximately USD 17.6 billion by 2033, up from USD 6.3 billion in 2023, reflecting a robust compound annual growth rate (CAGR) of 10.8% during the forecast period from 2024 to 2033.

One of the key factors contributing to this growth is the growing preference for plastic lumber as an eco-friendly alternative to traditional wood products. Plastic lumber is made from recycled materials, reducing the strain on natural resources. It helps mitigate environmental impact, making it an attractive option for residential and commercial construction projects.

Additionally, the durability, low maintenance, and resistance to weathering of plastic lumber make it popular in outdoor applications such as decking, fencing, and furniture. The rising trend of sustainable architecture, combined with stringent government regulations on construction materials, presents further opportunities for market expansion. As the construction industry continues to focus on green building solutions, plastic lumber is gaining popularity due to its cost-effectiveness, longer lifespan, and reduced environmental footprint.

Moreover, with the growing emphasis on reducing carbon footprints, plastic lumber’s ability to be reused and recycled further boosts its appeal in the market. The increasing demand from emerging economies, where infrastructure development and urbanization are rapidly expanding, also presents considerable opportunities for market growth.

The market is witnessing innovations in product offerings, such as the development of plastic lumber that mimics the aesthetic appeal of traditional wood, which further fuels consumer interest. As industries continue to prioritize sustainability and environmentally friendly solutions, the plastic lumber market is poised for continued expansion, driven by both market demand and evolving consumer preferences.

Key Takeaways

- Plastic Lumber Market size is expected to be worth around USD 17.6 Bn by 2033, from USD 6.3 Bn in 2023, growing at a CAGR of 10.8%.

- Virgin Plastic held a dominant market position in the plastic lumber sector, capturing more than a 53.3% share.

- Polyethylene held a dominant market position in the plastic lumber sector, capturing more than a 42.1% share.

- Molding and Trim held a dominant market position in the plastic lumber sector, capturing more than a 28.2% share.

- Asia Pacific (APAC) leads with a substantial 38.4% market share, translating to around USD 2.4 billion in revenue.

Plastic Lumber Statistics

Eco-Friendly Construction Revolution: Plastic Lumber Surge

- 13.1 million tons of plastic suitable for plastic lumber were generated in municipal solid waste.

- 1.0 million tons of plastic were recovered for beneficial purposes.

- 0.16 million tons of recovered plastics were converted into plastic lumber.

- 12.1 million tons of HDPE, LDPE, and PET plastics were incinerated or sent to landfills.

- In India, per capita plastic waste has grown from 700 grams to 2500 grams over five years.

Sustainable Building: Plastic Lumber’s Rising Popularity

- The U.S. Environmental Protection Agency recommends 75% post-consumer and 95% total recovered material content for plastic lumber.

- American Plastic Lumber, Inc. products contained less than 79% post-consumer content on average.

- About 8% of American Plastic Lumber, Inc. products contained no post-consumer recycled content at all.

- Nearly 7% of American Plastic Lumber, Inc. products were made with only 15% post-consumer content.

- India collects only 60% of its plastic waste, with the remaining 40% entering the environment directly as waste.

Emerging Trends

- Increased Use in Residential and Commercial Construction: Plastic lumber is gaining popularity in both residential and commercial construction due to its durability, low maintenance, and eco-friendly nature. It’s commonly used in decking, fencing, and outdoor furniture, as it can withstand weathering better than traditional wood.

- Integration of Recycled Materials: The growing trend of using recycled plastic in the production of lumber is helping to reduce waste and lower the environmental impact. Manufacturers are increasingly sourcing post-consumer plastic waste to create high-quality, sustainable plastic lumber, aligning with global sustainability goals.

- Advancements in Product Design: Innovations are focusing on improving the aesthetic appeal of plastic lumber. Modern designs that mimic the texture and appearance of natural wood are attracting homeowners and businesses looking for both sustainability and style in their outdoor spaces.

- Smart Cities and Infrastructure Development: The rise of smart cities and increasing investments in infrastructure projects are driving the demand for sustainable building materials like plastic lumber. As urbanization accelerates, the need for durable, long-lasting, and eco-friendly construction materials grows, making plastic lumber an ideal choice.

- Growing Popularity in Outdoor and Garden Applications: The versatility of plastic lumber for outdoor applications, including garden beds, landscaping, and park furniture, is fueling its demand. Its ability to resist moisture, pests, and decay makes it a preferred choice for outdoor environments.

Use Cases

- Decking and Patios: Plastic lumber is widely used for building durable, low-maintenance decking and patios. Its resistance to moisture, pests, and UV degradation makes it an ideal choice for outdoor living spaces, offering long-term performance without the need for frequent repairs or refinishing.

- Fencing: Plastic lumber is increasingly used for fences, especially in residential and commercial properties. It is highly resistant to weather conditions, preventing warping, cracking, or rotting, and offers an eco-friendly alternative to traditional wooden fences, requiring minimal upkeep over time.

- Outdoor Furniture: Plastic lumber is a popular material for outdoor furniture such as benches, picnic tables, and garden chairs. Its durability against the elements and low maintenance requirements make it a cost-effective and long-lasting choice for public parks, resorts, and home gardens.

- Boardwalks and Pathways: Plastic lumber is used to construct boardwalks and pathways in parks, beaches, and nature reserves. Its resilience to environmental wear and tear, combined with its slip-resistant surface, makes it a safe and sustainable option for high-traffic outdoor areas.

- Landscaping: In landscaping applications, plastic lumber is used for retaining walls, garden borders, and planters. It is favored for its ability to withstand moisture, prevent decay, and its ease of installation, making it a practical solution for various gardening and landscaping projects.

Major Challenges

- Higher Initial Cost: Although plastic lumber offers long-term savings due to its low maintenance and durability, the initial cost is often higher compared to traditional wood. This can deter some consumers or businesses, particularly in price-sensitive markets, from adopting it for large-scale projects.

- Limited Availability and Supply Chain Issues: The production of plastic lumber heavily relies on the availability of recycled plastic materials, which can be inconsistent. Supply chain disruptions, fluctuations in raw material costs, and limited recycling infrastructure can lead to delays and price volatility in the market.

- Aesthetic Perception: Despite improvements in design, some consumers still perceive plastic lumber as less aesthetically pleasing than natural wood. This perception can limit its adoption in high-end residential projects or areas where appearance plays a critical role in the overall design.

- Environmental Impact of Production: While plastic lumber is eco-friendly in terms of recycling and waste reduction, the manufacturing process still requires energy and may involve the use of non-renewable resources. This creates concerns regarding its overall carbon footprint, especially in regions with strict environmental regulations.

- Performance in Extreme Climates: In extremely hot or cold climates, plastic lumber can expand, contract, or warp, affecting its performance and durability. These temperature-related issues may limit its use in certain geographical areas, particularly for large-scale construction projects or in harsh environmental conditions.

Market Growth Opportunities

- Expanding Construction Industry: As global infrastructure and construction projects grow, there is increasing demand for sustainable building materials like plastic lumber. This presents a major opportunity for market expansion, especially in regions with rapid urbanization, where durable and eco-friendly materials are increasingly prioritized.

- Rising Popularity of Sustainable Products: The growing consumer preference for environmentally friendly products offers a significant opportunity for plastic lumber. As awareness about sustainability increases, both residential and commercial markets are more inclined to choose materials that are durable, recyclable, and made from recycled plastic.

- Innovation in Product Varieties: There is a growing opportunity for manufacturers to innovate by developing a wider range of plastic lumber products with different textures, colors, and designs. These innovations can cater to specific market needs, such as luxury outdoor furniture or customizable decking solutions, driving wider adoption.

- Government Regulations and Incentives: Increasing government regulations that promote the use of sustainable materials in construction, along with financial incentives for eco-friendly projects, create a favorable environment for plastic lumber. This could lead to wider adoption in both public infrastructure projects and private developments, boosting market growth.

- Growth in Outdoor and Recreational Spaces: With a rise in demand for parks, beaches, and recreational areas, plastic lumber is an ideal material for the construction of boardwalks, benches, and playgrounds. This growing focus on enhancing outdoor spaces offers new opportunities for the use of plastic lumber in public and commercial projects.

Key Players Analysis

- Trex Company, Inc. is a leading player in the plastic lumber industry, known for its high-performance composite decking products made from recycled wood fibers and plastics. Trex offers a range of eco-friendly, low-maintenance decking solutions and has established itself as a key brand in residential and commercial outdoor applications.

- Fiberon produces composite decking and fencing materials that combine recycled wood and plastic. The company is known for its commitment to sustainability, offering durable, weather-resistant products for both residential and commercial projects. Fiberon’s products are widely used for decking, railing, and other outdoor structures.

- Tangent Technologies, LLC specializes in manufacturing plastic lumber products using recycled plastics. The company offers a variety of sustainable solutions for decking, fencing, and furniture, providing durable alternatives to traditional wood. Their products are designed for outdoor use and are resistant to rot, decay, and environmental wear.

- Genova Products, Inc. is a manufacturer of PVC-based building materials, including plastic lumber for outdoor use. Genova focuses on providing eco-friendly, low-maintenance products for residential and commercial projects. The company’s products are popular in decking, fencing, and garden applications, offering long-lasting and weather-resistant solutions.

- PlasTEAK, Inc. manufactures plastic lumber products primarily used for outdoor furniture, decks, and boardwalks. Their offerings are made from recycled plastic, providing durable and sustainable alternatives to wood. PlasTEAK is known for creating long-lasting, eco-friendly products that are resistant to weathering and wear.

- PlasDECK, Inc. is a manufacturer of composite decking materials made from recycled plastics and wood fibers. Their products are highly durable and designed for long-term outdoor use, offering an environmentally friendly solution for decking, docks, and other structures. PlasDECK is a key player in the plastic lumber market.

- American Recycled Plastic, Inc. specializes in producing recycled plastic lumber used in a wide range of applications, from park benches to outdoor decking. The company focuses on providing sustainable and low-maintenance products that are resistant to weather and pests, offering an eco-friendly alternative to traditional lumber.

- KWK Plastic Lumber Co. Ltd. manufactures plastic lumber products for the construction, landscaping, and furniture industries. The company uses recycled plastic to create sustainable, durable alternatives to wood, offering solutions for decking, fencing, and outdoor furniture. KWK’s products are designed for long-lasting performance in various weather conditions.

- Ecoville produces plastic lumber from recycled plastic materials, offering sustainable solutions for the construction and outdoor furniture markets. Ecoville’s products are known for their durability, resistance to weathering, and eco-friendly characteristics, making them an attractive option for projects that prioritize sustainability.

- CMI manufactures a wide range of plastic lumber products for the construction and landscaping industries. Their products include decking, fencing, and structural components made from recycled plastics, which are durable and low-maintenance. CMI’s focus on sustainability and product innovation has helped it gain recognition in the market.

- Repeat Plastics Australia Pvt. Ltd. is a manufacturer of plastic lumber and other recycled plastic products. Their offerings include decking, fencing, and outdoor furniture, all made from 100% recycled materials. Repeat Plastics emphasizes the environmental benefits of their products, offering long-lasting, low-maintenance alternatives to traditional wood products.

- Engineered Plastic Systems LLC specializes in producing high-performance plastic lumber for a variety of outdoor applications. Their products are used in decking, park benches, and fencing, offering durable, weather-resistant solutions made from recycled plastics. Engineered Plastic Systems focuses on sustainability and performance in its product line.

- Century-Board USA, LLC manufactures plastic lumber products primarily used in construction, landscaping, and outdoor furniture. Century-Board’s products are made from 100% recycled plastics and are designed to be environmentally friendly, offering a sustainable alternative to wood with high resistance to wear and weathering.

- Advanced Environmental Recycling Technology Inc. (AERT) is a leading manufacturer of composite materials, including plastic lumber products. The company focuses on creating high-quality, sustainable products for decking, fencing, and other outdoor structures. AERT’s products are made from recycled materials, offering durability and resistance to the elements.

- Aeolian Enterprise Inc. produces recycled plastic lumber for outdoor use in applications such as decking, furniture, and landscaping. Aeolian’s products are designed to be durable, low-maintenance, and eco-friendly, offering an attractive alternative to traditional wood products while supporting sustainability initiatives.

- Bedford Technology LLC is a leading producer of recycled plastic lumber products for a variety of industries, including construction, landscaping, and transportation. Bedford’s products are known for their high strength, durability, and environmental benefits, offering sustainable alternatives to traditional materials like wood and concrete.

Conclusion

The Plastic Lumber Market is poised for significant growth driven by the increasing demand for sustainable building materials, environmental awareness, and innovations in product development. With a rising focus on eco-friendly alternatives, plastic lumber offers durability, low maintenance, and versatility for a variety of applications in construction, outdoor furniture, and infrastructure projects.

Despite challenges like higher initial costs and limited aesthetic appeal for some consumers, the market presents ample expansion opportunities, especially in regions experiencing rapid urbanization and infrastructure growth. As the demand for sustainable materials continues to grow, plastic lumber is expected to play a crucial role in shaping the future of construction and outdoor design.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)