Table of Contents

Overview

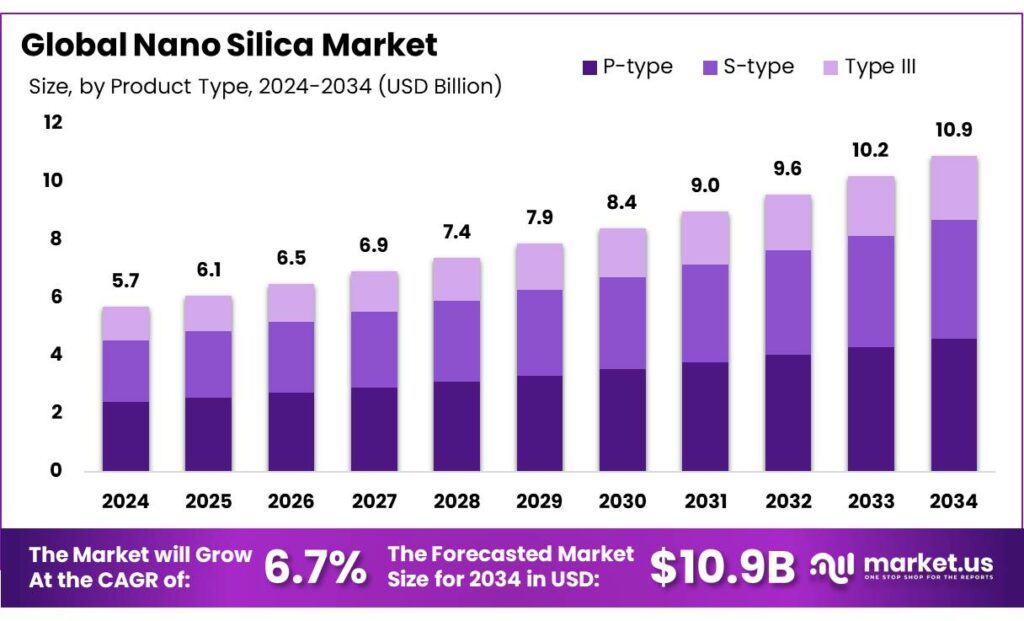

New York, NY – September 30, 2025 – The Global Nano Silica Market is projected to reach approximately USD 10.9 billion by 2034, up from USD 5.7 billion in 2024, reflecting a compound annual growth rate (CAGR) of 6.7% between 2025 and 2034. In 2024, Asia Pacific emerged as the leading regional market, accounting for over 41.2% of the share and generating USD 2.4 billion in revenue.

Nano silica, a form of silicon dioxide (SiO₂), consists of ultra-fine amorphous nanoparticles ranging from 5 to 100 nanometers. Its nanoscale size provides unique physical and chemical properties compared to conventional silica, making it highly valuable across industries. A key application lies in construction, where nano silica is used in high-performance concrete to enhance strength, durability, and resistance to environmental stress.

Beyond construction, nano silica is increasingly utilized in coatings, composites, and advanced drug delivery systems. The automotive and tire industries are also adopting nano silica to improve performance and sustainability. In recent years, growing emphasis on eco-friendly production has encouraged the development of nano silica from renewable resources, such as rice husk ash.

However, the market faces challenges due to rising concerns over health and environmental risks associated with nanoparticles and silica dust. Addressing these issues through regulation, safer production methods, and technological innovation will be crucial for ensuring sustainable growth in the coming decade.

Key Takeaways

- The Global Nano Silica Market was valued at USD 5.7 billion in 2024, at a CAGR of 6.7% and is estimated to reach USD 10.9 billion by 2034.

- Based on product types, nano silica, which belongs to the p-type, dominated the market in 2024, comprising about 42.1% share of the total global market.

- Among the applications of nano silica in commercial settings, the concrete manufacturing industry dominated the market in 2024, accounting for around 34.1% of the market share.

- Asia Pacific was the largest market for nano silica in 2024 due to its rapidly expanding construction and infrastructure industry.

➤ Curious about the content? Explore a sample copy of this report – https://market.us/report/global-nano-silica-market/request-sample/

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2024) | USD 5.7 Billion |

| Forecast Revenue (2034) | USD 10.9 Billion |

| CAGR (2025-2034) | 6.7% |

| Segments Covered | By Product Type (P-type, S-type, Type III), By Applications (Concrete, Rubber, Paints & Coatings, Adhesives & Sealants, Electronics, Pharmaceuticals, Others) |

| Competitive Landscape | Evonik Industries AG, Cabot Corporation, AkzoNobel N.V., DuPont, Wacker Chemie AG, NanoPore Incorporated, NanoAmor (Nanostructured & Amorphous Materials), Fuso Chemical Co., Ltd., nanoComposix, Bee Chems, PPG Industries, nanoComposix, Other Key Players |

➤ Directly purchase a copy of the report – https://market.us/purchase-report/?report_id=157338

Key Market Segments

Product Type Analysis

The nano silica market is categorized by product type into P-type, S-type, and Type III. In 2024, P-type nano silica held the largest market share at 42.1%. Its dominance stems from a higher pore rate of 0.61 ml/g, which results in a larger specific surface area and enhanced UV reflectivity compared to the S-type.

The porous structure of P-type nano silica, characterized by numerous nano-pores, makes it ideal for applications such as reinforced fillers in concrete and additives in rubber and plastics. Its superior UV reflectivity also enhances its effectiveness in construction and coating applications, providing better protection against UV degradation and extending material lifespan.

Application Analysis

In 2024, the concrete sector accounted for 34.1% of global nano silica consumption, surpassing other industries like rubber, paints & coatings, adhesives & sealants, electronics, and pharmaceuticals. Nano silica enhances concrete by refining its pore structure, acting as a pozzolanic material to increase calcium silicate hydrate (C-S-H) gel formation, and serving as nucleation sites for C-S-H growth.

These properties improve compressive, flexural, and bond strength while reducing permeability and water absorption, leading to greater durability. Although nano silica may increase water demand and affect setting times in fresh concrete, it significantly boosts the strength, density, and longevity of hardened concrete.

Regional Analysis

The Asia Pacific region led the global nano silica market in 2024, capturing a 41.2% revenue share, valued at approximately USD 2.4 billion, with China and India as key contributors. The region’s leadership is driven by its booming construction industry, particularly in developing nations. For example, India’s Construction Industry Development Council notes that construction is the country’s second-largest GDP contributor after agriculture.

Similarly, China’s National Bureau of Statistics reported real estate development investments of 5,252.9 billion yuan in the first half of 2024. Rising demand for advanced materials in electronics, automotive, and healthcare sectors further fuels nano silica’s role in enhancing product performance and durability across the region.

Top Use Cases

- Construction Enhancement: Nano silica acts as a key additive in concrete mixes, filling tiny gaps to create denser, stronger structures that resist cracks and water penetration. This boosts overall durability, making buildings and roads last longer while reducing repair needs. As a market analyst, I see this driving demand in booming infrastructure projects worldwide, where tougher materials cut long-term costs.

- Rubber and Tire Reinforcement: In rubber production, nano silica serves as a filler to improve strength, flexibility, and wear resistance, especially in tires and seals. It helps tires grip better on wet roads and endure rough conditions without degrading quickly. From my analysis, this use case is surging with the rise in vehicle production, enhancing safety and performance in the automotive sector.

- Coatings and Paint Protection: Nano silica is blended into paints and coatings to add UV resistance and scratch-proof qualities, keeping surfaces looking new despite sun exposure and daily wear. This extends the life of outdoor structures like bridges and cars. As an analyst, I note its growing role in eco-friendly formulations, meeting demands for sustainable building materials.

- Drug Delivery Innovation: In medicine, nanosilica particles carry drugs directly to targeted body areas, releasing them slowly for better treatment of diseases like cancer. Their porous design protects meds from breaking down too soon. My market insights highlight this as a breakthrough, with healthcare firms investing heavily to improve patient outcomes and reduce side effects.

- Agriculture Boost: Nano silica is applied as a soil amendment or foliar spray to help plants absorb nutrients more efficiently, strengthening roots and leaves against pests and drought. This leads to healthier crops with higher yields. Analyzing trends, I observe its potential in sustainable farming, addressing food security challenges as global populations grow.

Recent Developments

1. Evonik Industries AG

Evonik is expanding its silica production with a strong focus on sustainable mobility. Their recent developments include highly dispersible, precipitated silica for the green tire industry, improving fuel efficiency, and reducing tire wear. They are also innovating in fumed silica for high-performance battery separators and advanced coatings, supporting the electric vehicle sector. Their research continues to enhance material performance while reducing environmental impact.

2. Cabot Corporation

Cabot Corporation is advancing its engineered silica solutions, particularly for sustainable transportation. A key development is their ENERMAX portfolio, which includes high-strength nano silicas that significantly improve the rolling resistance and durability of green tires. They are also expanding capacity and developing new fumed silica grades for silicone rubber, adhesives, and energy storage applications, focusing on performance and processing benefits for customers.

3. DuPont

Through its acquisition of Laird Performance Materials, DuPont is a key player in thermal management. Their recent work involves using functionalized nano silica within thermal interface materials (TIMs) and gap fillers for electronics and electric vehicles. These silica-based materials provide superior thermal conductivity and electrical insulation, which is critical for managing heat in high-power 5G infrastructure, advanced computing, and automotive radar systems.

4. Wacker Chemie AG

Wacker is focusing on the development of hydrophobic fumed silica, a key ingredient in silicone rubber for the construction and electronics industries. Their recent innovations include HDK brand silica grades that enhance the mechanical strength, transparency, and rheological control of silicone sealants and coatings. They are also advancing silica applications in defoamers and for improving the processability of composite materials.

5. NanoPore Incorporated

NanoPore specializes in proprietary silica aerogel technology, focusing on thermal insulation. A recent key development is their Spaceloft Subsea product, designed for insulating pipelines in deep-water oil and gas applications. Their hydrophobic silica aerogels provide exceptional thermal performance in harsh environments. They continue to innovate in making high-performance, flexible aerogel blankets more accessible for industrial, building, and subsea insulation.

Conclusion

Nano Silica is a transformative material poised for widespread adoption across industries. Its unique ability to enhance strength, protect against wear, and enable precise delivery in treatments makes it indispensable for future innovations. With ongoing advancements in production and applications, nano silica promises to support sustainable growth, from greener construction to smarter healthcare solutions, solidifying its role in a rapidly evolving global economy.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)