Table of Contents

Overview

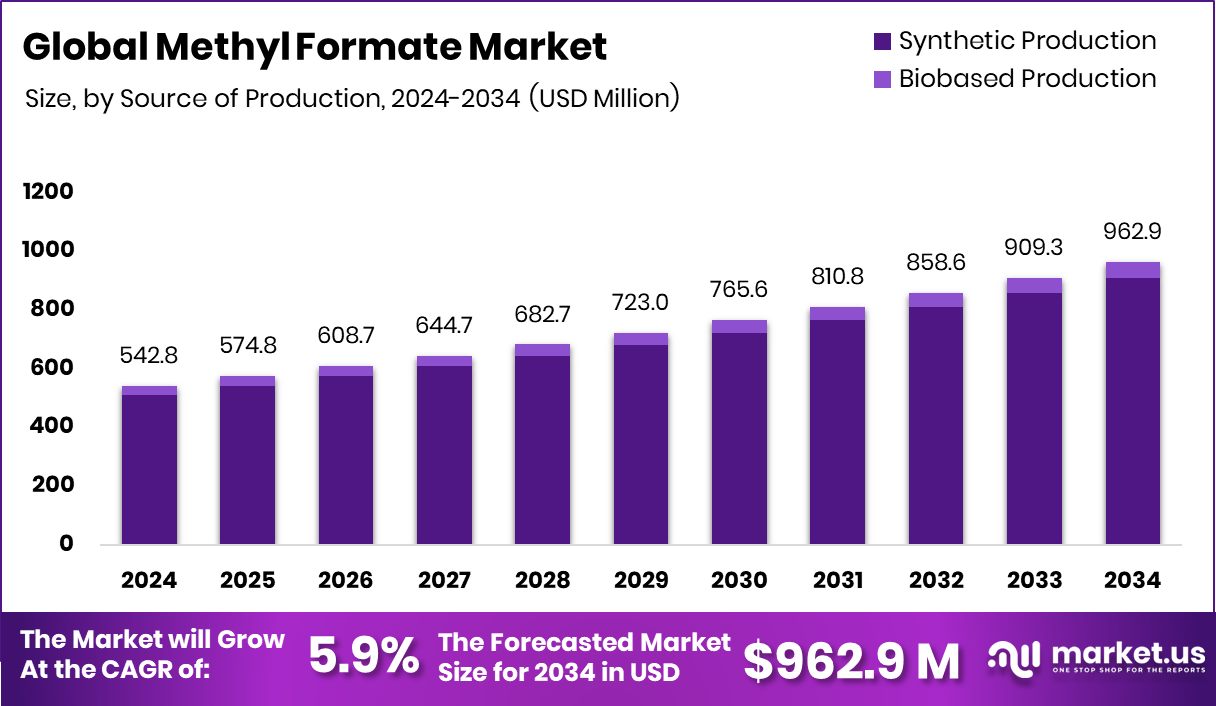

New York, NY – Nov 07, 2025 – The global Methyl Formate Market is projected to reach USD 962.9 million by 2034, rising from USD 542.8 million in 2024 at a 5.9% CAGR (2025–2034), with Asia-Pacific maintaining dominance at 39.7%.

Methyl formate, a clear and flammable liquid with an ether-like scent, is primarily used as a chemical intermediate and eco-friendly solvent. Produced from methanol and carbon monoxide, it’s vital in the production of formic acid, dimethylformamide, and polyurethane foams. Its low toxicity and sustainable profile make it an ideal alternative to ozone-depleting blowing agents.

Growth is driven by rising industrial activity, especially in Asia, and stricter sustainability regulations. The KLJ Group’s Rs. 1,200 Cr investment in plasticizers and phthalic anhydride is expected to improve feedstock supply for methyl formate synthesis. Additionally, India Agri Business Fund II’s US$15 million investment supports agricultural modernization, indirectly benefiting methyl formate use in agrochemical synthesis. The compound’s growing adoption in foams, coatings, and adhesives further strengthens market demand.

Emerging opportunities are seen in the synthetic fuel and biotech sectors, with Rivan’s US$13 million funding for sustainable fuels and Ansa’s US$54.4 million for DNA synthesis signaling methyl formate’s expanding role in green chemical and advanced industrial applications.

➤ Click the sample report link for complete industry insights: https://market.us/report/global-methyl-formate-market/request-sample/

Key Takeaways

- The Global Methyl Formate Market is expected to be worth around USD 962.9 million by 2034, up from USD 542.8 million in 2024, and is projected to grow at a CAGR of 5.9% from 2025 to 2034.

- In 2024, the Methyl Formate Market was dominated by synthetic production, capturing 94.3% share.

- The Methyl Formate Market saw a 31.2% share from its use as a solvent in chemical processes.

- In 2024, the chemicals industry led the Methyl Formate Market with 37.4% overall market share.

- The Asia-Pacific market value reached USD 215.8 million, driven by industrial expansion.

➤ Directly purchase a copy of the report – https://market.us/purchase-report/?report_id=163934

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2024) | USD 542.8 Million |

| Forecast Revenue (2034) | USD 962.9 Million |

| CAGR (2025-2034) | 5.9% |

| Segments Covered | By Source of Production (Synthetic Production, Biobased Production), By Application (Solvent in Chemical Processes, Intermediate in Esters Production, Agricultural Chemicals, Pharmaceuticals, Plasticizers, Others), By End-Use (Chemicals Industry, Agriculture, Pharmaceuticals, Automotive, Textiles, Others) |

| Competitive Landscape | BASF, Eastman, Triveni Chemicals, Tradex Corporation, Rao A. Group, Mitsubishi Gas Chemical, Chevron Chemical Company, Others |

Key Market Segments

By Source of Production Analysis

In 2024, Synthetic Production dominated the By Source of Production segment in the Methyl Formate Market, accounting for a commanding 94.3% share. This leadership stems from its efficient, large-scale process combining methanol and carbon monoxide, ensuring high purity and cost-effectiveness. The synthetic route provides superior control over reaction conditions and yields, making it the preferred method for industries producing polymers, coatings, and agrochemicals.

Its scalability aligns seamlessly with modern chemical infrastructure, enabling consistent output to meet industrial demand. Continued investments in advanced chemical facilities and sustainable production technologies further reinforce synthetic production’s dominance, positioning it as the most reliable and adaptable approach for global methyl formate manufacturing.

By Application Analysis

In 2024, Solvent in Chemical Processes led the By Application segment of the Methyl Formate Market, securing a 31.2% share. This dominance is attributed to methyl formate’s excellent solvency, rapid evaporation rate, and broad compatibility with various resins and polymers. It serves as a cost-effective, eco-friendly substitute for traditional volatile organic solvents, making it highly favored in industrial formulations.

Widely used in coatings, adhesives, and chemical intermediate production, the compound enhances process efficiency and blending performance. As industries increasingly prioritize sustainable and low-emission formulations, methyl formate’s solvent applications remain the primary driver of demand, reinforcing its leadership within the global market landscape.

By End-Use Analysis

In 2024, the Chemicals Industry dominated the By End-Use segment of the Methyl Formate Market, commanding a 37.4% share. This dominance is driven by methyl formate’s vital role as an intermediate in producing formic acid, dimethylformamide, and several other downstream derivatives. Its high purity, versatility, and reaction efficiency make it indispensable for diverse synthesis processes across the sector.

The compound’s adaptability to large-scale production and alignment with sustainable chemical practices further bolster its use. With continuous expansion in global chemical manufacturing and a rising shift toward eco-friendly synthesis routes, the chemical industry remains the largest consumer of methyl formate, reinforcing its central role in industrial chemical applications.

Regional Analysis

In 2024, Asia-Pacific dominated the Methyl Formate Market, holding a 39.7% share valued at USD 215.8 million. This strong position is fueled by rapid industrialization in China and India, expanding chemical production, and increasing agrochemical applications. North America shows mature but slower growth, supported by its established chemical and solvent industries.

Europe maintains stability with steady demand driven by stringent environmental norms and rising adoption of low-emission solvents. Meanwhile, the Middle East & Africa market remains limited due to lesser industrial diversification, while Latin America exhibits moderate growth supported by developments in coatings and agrochemicals.

Top Use Cases

- Blowing agent in foam production: Methyl formate is used as a “blowing agent” in the manufacture of polyurethane foams, replacing ozone-depleting chemicals. It creates the gas bubbles that turn liquid resin into foam insulation or foam panels.

- Solvent for coatings, adhesives and resin: Thanks to its strong solvency and rapid evaporation, methyl formate works as a solvent in paints, coatings, adhesives, and cleaning products, dissolving polymers and enabling fast drying.

- Intermediate for chemical synthesis: In chemical manufacturing, methyl formate serves as a building block (intermediate) to make derivatives like formic acid, dimethylformamide (DMF) and other organic compounds.

- Fumigant and pest-control agent: It’s used in agriculture and storage applications as a fumigant to control insects in stored grains, dried fruit and timber, due to its ability to penetrate and act safely compared to older chemicals.

- Refrigerant (historical / niche use): Although largely replaced now, methyl formate was once used as a refrigerant in domestic refrigerators because of its low boiling point and alternative status to sulfur dioxide.

- Source of formyl group in organic synthesis: It can act as a “formyl‐group donor” in advanced chemical reactions: for example, methyl formate-water mixtures are explored for hydroformylation and tandem synthetic pathways, enabling creative organic molecule construction.

Recent Developments

- In August 2025, Eastman announced a strategic partnership with Huafon Chemical Co., Ltd. to build a local facility in China dedicated to producing cellulose acetate yarn (under Eastman’s Naia™ brand). This move strengthens Eastman’s textile-materials footprint in the region and underscores its global manufacturing expansion strategy.

- In May 2025, BASF signed an agreement to acquire the remaining 49% share of the company Alsachimie from DOMO Chemicals, becoming the sole owner of the polyamide-6.6 precursor producer at Chalampé, France. This move strengthens BASF’s raw-material value chain for engineering plastics, indirectly supporting its broader chemical intermediates business (which includes methyl formate production).

Conclusion

The Methyl Formate market is gaining momentum as industries move toward cleaner and sustainable chemical solutions. Its versatility as a solvent, blowing agent, and chemical intermediate supports a wide range of applications in coatings, foams, and agrochemicals. With growing emphasis on green manufacturing and regulatory compliance, methyl formate continues to attract attention as an eco-friendly alternative to conventional solvents.

Expanding industrial infrastructure, especially in developing regions, is boosting its production and application potential. As technology advances in synthetic processes and renewable feedstocks, methyl formate is poised to play a vital role in the transition toward low-emission chemical production.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)