Table of Contents

Overview

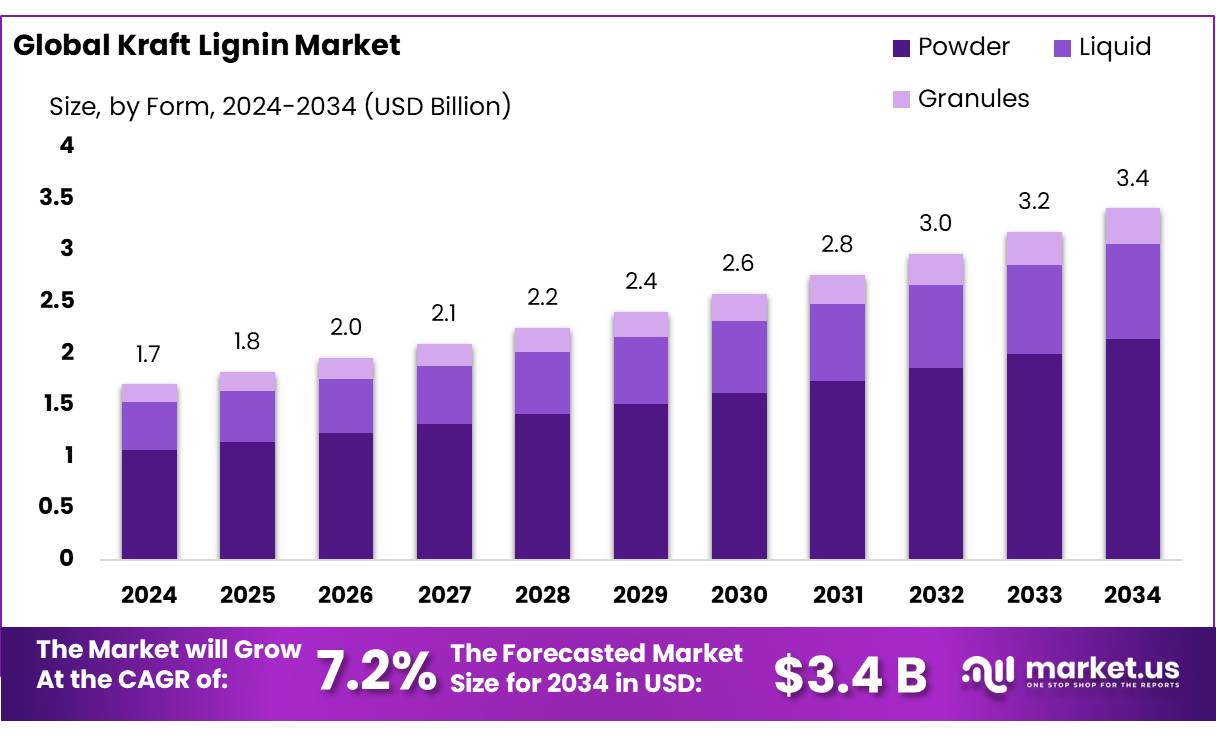

New York, NY – August 11, 2025 – The Global Kraft Lignin Market is projected to grow from USD 1.7 billion in 2024 to approximately USD 3.4 billion by 2034, achieving a CAGR of 7.2% during the forecast period from 2025 to 2034. In 2024, North America led the market, holding a 48.2% share with USD 0.8 billion in revenue.

Kraft lignin, a high-purity biopolymer extracted during the kraft pulping process, is gaining traction as a key material in the shift toward sustainable solutions. By 2023, global kraft lignin production capacity reached around 112 kt annually, driven by its increasing use in applications such as bio-based adhesives, carbon fibers, and phenolic resins.

Major production facilities, such as Stora Enso’s Sunila mill in Finland, produce 50,000 metric tons of lignin yearly. Additionally, Södra’s upcoming facility in Sweden, set to begin operations in 2027, is expected to become the world’s largest kraft lignin production site, further highlighting lignin’s industrial potential.

In India, government initiatives like ‘Make in India’ are promoting lignin use. For example, Praj Industries has developed lignin-based bio-bitumen, successfully replacing up to 15% of conventional bitumen in road construction. The government also permits up to 35% lignin integration in petroleum-based bitumen to reduce reliance on imports and support sustainability.

Key Takeaways

- The Global Kraft Lignin Market is expected to grow from USD 1.7 billion in 2024 to approximately USD 3.4 billion by 2034, registering a CAGR of 7.2%.

- Powder form held the dominant position, capturing more than 62.8% of the total market share.

- Softwood was the leading source, accounting for over 57.1% of the market share.

- Adhesives emerged as the top application, holding more than 31.3% of the global market.

- The Construction sector led the market, with a dominant share of over 34.6%.

- North America accounted for approximately 48.2% of the global Kraft Lignin Market, with a regional value estimated at USD 0.8 billion in 2024.

➤ Curious about the content? Explore a sample copy of this report – https://market.us/report/global-kraft-lignin-market/request-sample/

Report Scope

| Market Value (2024) | USD 1.7 Billion |

| Forecast Revenue (2034) | USD 3.4 Billion |

| CAGR (2025-2034) | 7.2% |

| Segments Covered | By Form (Powder, Liquid, Granules), By Source (Softwood, Hardwood, Hybrid), By Application (Adhesives, Carbon Fiber Production, Animal Feed, Bioresins, Soil Conditioning, Others), By End Use (Construction, Agriculture, Food Beverage, Pharmaceutical, Personal Care, Others) |

| Competitive Landscape | Borregaard Lignotech, Domtar Corporation, NIPPON PAPER INDUSTRIES CO. LTD, Rayonier Advanced Materials, Resolute Forest Products, Stora Enso, Suzano, UPM Biochemicals, West Fraser, WestRock Company, Weyerhaeuser Company |

➤ Directly purchase a copy of the report – https://market.us/purchase-report/?report_id=153906

Key Market Segments

By Form Analysis

In 2024, the powder form of kraft lignin commanded a 62.8% share of the market, driven by its ease of handling, storage, and transportation. Its high solubility and stability under diverse environmental conditions make it ideal for applications in adhesives, coatings, and dispersants across construction, agriculture, and chemical industries.

The powder’s ability to blend seamlessly with other dry materials enhances its industrial versatility. In 2025, demand for powdered kraft lignin is expected to grow steadily, fueled by its use in eco-friendly product formulations and ongoing research into lignin-based biopolymers.

By Source Analysis

Softwood held a 57.1% share of the kraft lignin market in 2024, attributed to its higher lignin content compared to hardwoods, enabling more efficient extraction and consistent yields. Its robust structural properties make softwood-derived lignin a preferred choice for resins, binders, and dispersants.

The strong fiber structure of softwood also supports efficient processing in pulping and chemical conversion. In 2025, demand for softwood-based kraft lignin is projected to remain robust, particularly in industries prioritizing bio-based materials with reliable quality and supply.

By Application Analysis

Adhesives accounted for a 31.3% share of the kraft lignin market in 2024, driven by the shift toward sustainable, bio-based formulations. Kraft lignin’s natural bonding properties make it an effective alternative to synthetic resins, particularly in wood adhesives and construction applications.

Its low toxicity, biodegradability, and cost-effectiveness appeal to manufacturers aiming to reduce petroleum-based inputs. In 2025, demand for lignin-based adhesives is expected to grow, supported by green building standards and increasing use in packaging, furniture, and automotive sectors.

By End Use Analysis

The construction sector captured a 34.6% share of the kraft lignin market in 2024, driven by demand for sustainable building materials. Kraft lignin is widely utilized in concrete admixtures, plasterboard binders, and insulation due to its water-reducing, dispersing, and binding properties.

It enhances material strength and durability while lowering environmental impact, aligning with green building initiatives. In 2025, the construction industry’s reliance on kraft lignin is expected to persist, supported by regulations promoting low-emission materials and circular economy practices in infrastructure.

Regional Analysis

In 2024, North America held a commanding 48.2% share of the global kraft lignin market, valued at approximately USD 0.8 billion. This dominance is driven by robust adoption of kraft lignin in applications such as construction chemicals, adhesives, agriculture, and carbon-based materials.

The region’s leadership is supported by stringent environmental regulations and sustainability initiatives promoting bio-based and circular economy materials. The United States and Canada have prioritized investments in biorefinery development and lignin valorization, fostering innovation and infrastructure growth.

This has spurred demand for kraft lignin as a low-carbon, renewable feedstock across multiple industries. In 2025, North America is projected to maintain its leading position, driven by sustained demand for eco-friendly resins, dispersants, and agricultural additives. The region’s strong market share reflects its innovative momentum, supportive regulatory framework, and reliable feedstock supply chains.

Top Use Cases

- Bio-Based Adhesives: Kraft lignin is widely used in adhesives for wood products and construction. Its natural bonding properties make it a sustainable alternative to synthetic resins, offering lower toxicity and biodegradability. This supports eco-friendly manufacturing in furniture, packaging, and automotive industries, meeting the growing demand for green materials.

- Carbon Fiber Production: Kraft lignin serves as a renewable raw material for producing carbon fibers. These lightweight, strong fibers are used in the automotive and aerospace industries to reduce vehicle weight and improve fuel efficiency. Lignin-based carbon fibers are cost-effective and align with sustainability goals, driving their adoption.

- Concrete Additives: In construction, kraft lignin is used as a dispersant in concrete admixtures. It improves workability, reduces water usage, and enhances strength in cement-based materials. Its eco-friendly nature supports green building standards, making it a popular choice for sustainable infrastructure projects.

- Fertilizers and Pesticides: Kraft lignin acts as a binder and dispersant in fertilizers and pesticides. It enables controlled-release formulations, improving nutrient delivery and reducing environmental impact. Its use in agriculture supports sustainable farming practices, meeting the demand for eco-friendly soil and crop management solutions.

- Bioplastics: Kraft lignin is used to create bio-based plastics, replacing petroleum-based materials. Its versatility allows for applications in packaging and consumer goods. As industries shift toward sustainable materials, lignin-based bioplastics offer a biodegradable, cost-effective option, driving innovation in the plastics market.

Recent Developments

1. Borregaard Lignotech

Borregaard continues to lead in lignin-based innovations, focusing on sustainable alternatives to fossil-based materials. Recently, they expanded their BioPiva lignin product line for animal nutrition and LignoBoost technology for high-purity lignin extraction. Their lignin is also used in bio-based dispersants and adhesives. Borregaard collaborates with research institutions to enhance lignin applications in carbon fibers and batteries.

2. Domtar Corporation

Domtar has been advancing its BioChoice lignin, used in agricultural, construction, and industrial applications. They partnered with LignoFlow to optimize lignin extraction from pulp mills. Domtar is also exploring lignin’s role in biodegradable plastics and asphalt modifiers. Their R&D focuses on improving lignin’s functionality in sustainable materials.

3. Nippon Paper Industries Co. Ltd

Nippon Paper is investing in lignin-based carbon materials for batteries and energy storage. They’ve developed lignin-derived hard carbon for lithium-ion battery anodes, enhancing sustainability in EVs. Additionally, they are researching lignin’s use in resins and adhesives to replace petroleum-based chemicals.

4. Rayonier Advanced Materials

Rayonier Advanced Materials (RYAM) is scaling up lignin production for bio-based chemicals and materials. Their GreenCircle initiative promotes lignin as a renewable alternative in coatings, resins, and composites. RYAM is also exploring lignin’s potential in water treatment and agrochemicals.

5. Resolute Forest Products

Resolute has been optimizing lignin extraction for use in bio-based polyols and phenolic resins. They collaborate with universities to develop lignin applications in 3D printing and sustainable packaging. Resolute’s lignin research supports circular economy goals in the pulp and paper industry.

Conclusion

Kraft Lignin is a versatile, sustainable biopolymer driving innovation across industries like construction, agriculture, and automotive. Its applications in adhesives, carbon fibers, concrete additives, fertilizers, and bioplastics align with global demand for eco-friendly materials. With growing production capacities and technological advancements, the kraft lignin market is poised for significant growth, supporting circular economy goals and reducing reliance on fossil-based resources.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)