Table of Contents

Overview

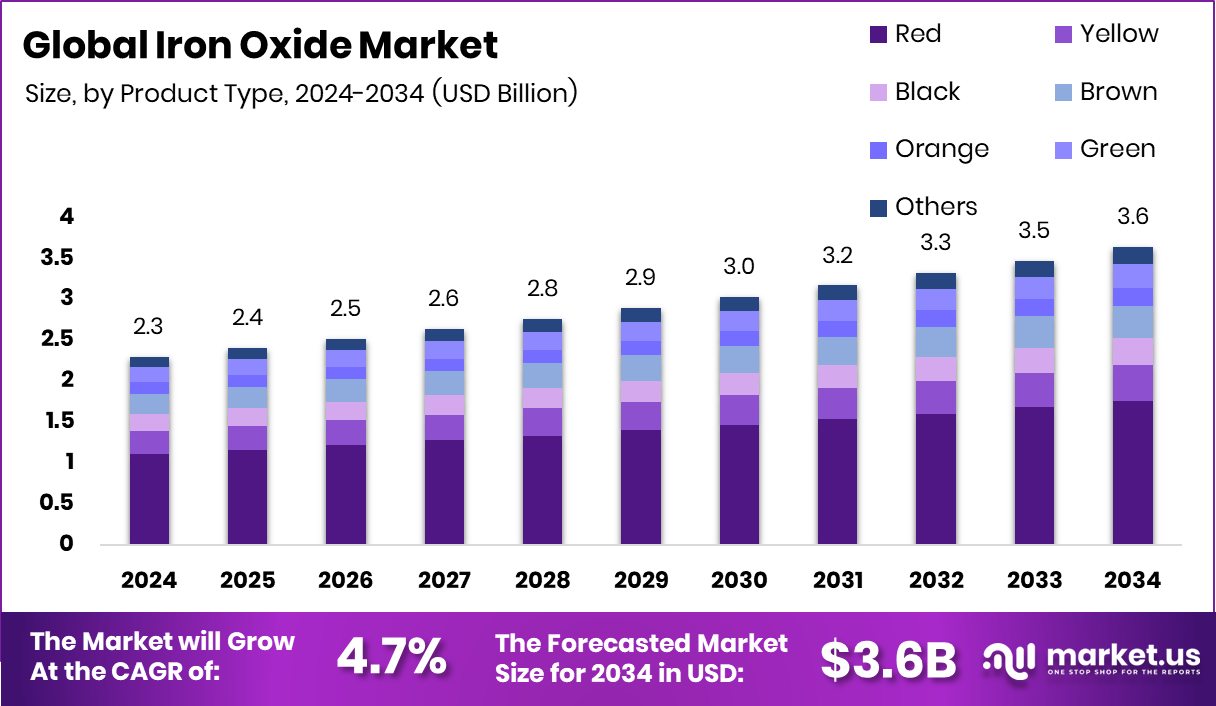

New York, NY – Nov 05, 2025 – The global iron oxide market is projected to grow from USD 2.3 billion in 2024 to approximately USD 3.6 billion by 2034, reflecting a compound annual growth rate (CAGR) of around 4.7% between 2025 and 2034. North America currently commands a dominant market share, accounting for about 47.9%, largely driven by ongoing infrastructure upgrades.

Iron oxides—typically in forms such as FeO, Fe₂O₃, and Fe₃O₄—occur naturally (for example, as hematite) and are also synthetically produced. Their appeal lies in their chemical stability, wide color palette (yellow/orange/red/brown/black), affordability, and versatility across pigment, catalytic, and structural applications.

The market encompasses the production, trade, and application of iron oxide compounds, segmented by grade (pigment-grade, nano-grade), technology, and end-use industries, including paints & coatings, plastics, construction, catalysts, and magnetic materials. Growth is being fuelled by escalating demand for high-performance pigments in coatings and construction materials, in line with global urbanization and infrastructure expansion. The shift towards eco-friendly coatings—evidenced by, e.g., the €21 million raised by Ecoat to reinvent sustainable paints—supports iron-oxide-based pigment alternatives.

Beyond pigments, iron oxides are gaining use in functional applications such as magnetic materials, electronics, and novel construction additives. Industry restructuring and downstream investment—such as the US$2.5 billion bidding for a coatings maker and the US$2.3 billion acquisition of AOC by Nippon Paint—are translating upstream into higher raw material demand. Even modest support, like a £2,500 grant to a UK industrial paint specialist in Walsall, underscores local innovation potential and bespoke iron-oxide solutions.

➤ Click the sample report link for complete industry insights: https://market.us/report/global-iron-oxide-market/request-sample/

Key Takeaways

- The Global Iron Oxide Market is expected to be worth around USD 3.6 billion by 2034, up from USD 2.3 billion in 2024, and is projected to grow at a CAGR of 4.7% from 2025 to 2034.

- In 2024, the Iron Oxide Market saw red pigments dominate with a 48.3% strong global share.

- The Iron Oxide Market recorded a 36.2% share from construction, driven by colored concrete and tiles.

- The North American strong construction and coatings industries significantly supported this USD 1.1 billion valuation.

➤ Directly purchase a copy of the report – https://market.us/report/global-iron-oxide-market/request-sample/

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2024) | USD 2.3 Billion |

| Forecast Revenue (2034) | USD 3.6 Billion |

| CAGR (2025-2034) | 4.7% |

| Segments Covered | By Product Type (Red, Yellow, Black, Brown, Orange, Green, Others), By Application (Construction, Paints and Coatings, Plastics, Chemicals, Paper and Pulp Manufacturing, Others) |

| Competitive Landscape | Lanxess AG, Huntsman International LLC, Toda Kogyo Corporation, Alabama Pigments Company, LLC, Golccha Pigments Pvt. Ltd., Tata Pigments Company, Yaroslavsky Pigment Company, Cathey Industries, Others |

Key Market Segments

By Product Type Analysis

In 2024, Red iron oxide dominated the By Product Type segment of the Iron Oxide Market, capturing a 48.3% share. Its leadership stems from extensive use as a pigment in paints, coatings, and construction materials, owing to its colour stability, UV resistance, and non-toxicity. Red iron oxide’s cost efficiency and versatility also make it popular in cement, ceramics, and plastics applications. Its broad availability and ability to deliver consistent hues reinforce its status as the preferred choice for architectural and decorative coatings.

Supported by a global construction boom and infrastructure expansion, demand for red iron oxide continues to strengthen. Its reliability, durability, and eco-friendly nature ensure its continued dominance across both industrial and decorative applications, making it a cornerstone material in the global iron oxide pigment landscape.

By Application Analysis

In 2024, the Construction sector led the By Application segment of the Iron Oxide Market, commanding a 36.2% share. This leadership is driven by the widespread use of iron oxide pigments in cement, tiles, pavers, and architectural coatings, where they deliver durable and visually appealing finishes. Renowned for their high coloring strength, UV stability, and weather resistance, iron oxides are key additives in concrete and building materials, ensuring lasting performance even in harsh conditions. Their color consistency and resilience make them ideal for large-scale infrastructure and residential projects.

Moreover, the rising preference for decorative and eco-friendly construction materials has strengthened the global demand for these pigments. As sustainable architecture and aesthetic urban designs gain traction, iron oxide pigments continue to play a central role in enhancing both the functionality and appearance of modern construction materials worldwide.

Regional Analysis

In 2024, North America dominated the global Iron Oxide Market, holding a 47.90% share valued at USD 1.1 billion. This leadership is driven by robust demand from the construction, coatings, and infrastructure sectors, where iron oxide pigments are prized for their durability, colour stability, and resistance to weathering.

Europe followed with steady growth supported by the adoption of eco-friendly pigments in building materials and industrial coatings, aligned with regional sustainability initiatives. The Asia Pacific region showed consistent expansion, propelled by rapid industrialization and large-scale infrastructure projects.

Meanwhile, Latin America and the Middle East & Africa are witnessing gradual increases in consumption, supported by urban development and modernization efforts. Together, these dynamics reflect a balanced global landscape, where advanced economies drive innovation and emerging regions strengthen market diversification, ensuring the iron oxide market’s continued global stability and long-term growth potential.

Top Use Cases

- Pigments in paints and coatings: Iron oxide pigments deliver rich colours like red, yellow, brown and black. They are widely used in paints and coatings because of their excellent colour stability, UV resistance, and non-toxicity.

- Colouring concrete & construction materials: Iron oxide pigments are added to concrete, tiles, pavers and architectural finishes to give durable decorative colour that resists weathering and retains colour over time.

- Plastics and rubber colouring: They are used in plastics (PVC, polyolefins) and rubber to provide colour while being cost-effective and chemically stable.

- Functional additives in construction materials: Beyond decoration, iron oxides can serve as nanopigments or nanofillers in concrete mixes to enhance strength, water/frost resistance, and colour uniformity.

- Magnetic and electronic materials: Certain iron-oxide compounds are used in magnetic coatings, electronic applications, and as catalysts because they combine iron’s properties with stable oxide chemistry.

- Environmental & remediation uses: Iron oxide materials (often nanoscale) can be used to remove pollutants or dyes from water, thanks to their high surface area and reactive surfaces.

Recent Developments

- In May 2025, Huntsman announced the opening of a new E-GRADE® purification & packaging unit at their Conroe, Texas site (within their Performance Products division). This new facility focuses on high-purity metal amines and amine oxides, primarily for semiconductor and advanced industrial applications.

- In January 2024, LANXESS teamed up with IBU-tec to develop iron oxides destined for the cathode material of lithium-iron-phosphate (LFP) batteries. The aim: improve energy density, charging speed, and cycle life of LFP batteries and build a more local (European) value chain for this raw material.

Conclusion

The Iron Oxide market continues to expand, driven by its diverse applications in industries like construction, coatings, and pigments. The material’s versatility, coupled with its durability, weather resistance, and non-toxicity, makes it a preferred choice across various sectors. As global demand for sustainable and high-performance materials grows, iron oxide’s role in eco-friendly pigments and innovative construction materials becomes increasingly significant.

Furthermore, its expanding use in industrial and functional applications, such as in electronics and water treatment, highlights its essential contribution to modern technological advancements. The market outlook remains positive, fueled by ongoing product innovations and regional demand growth.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)