Table of Contents

Overview

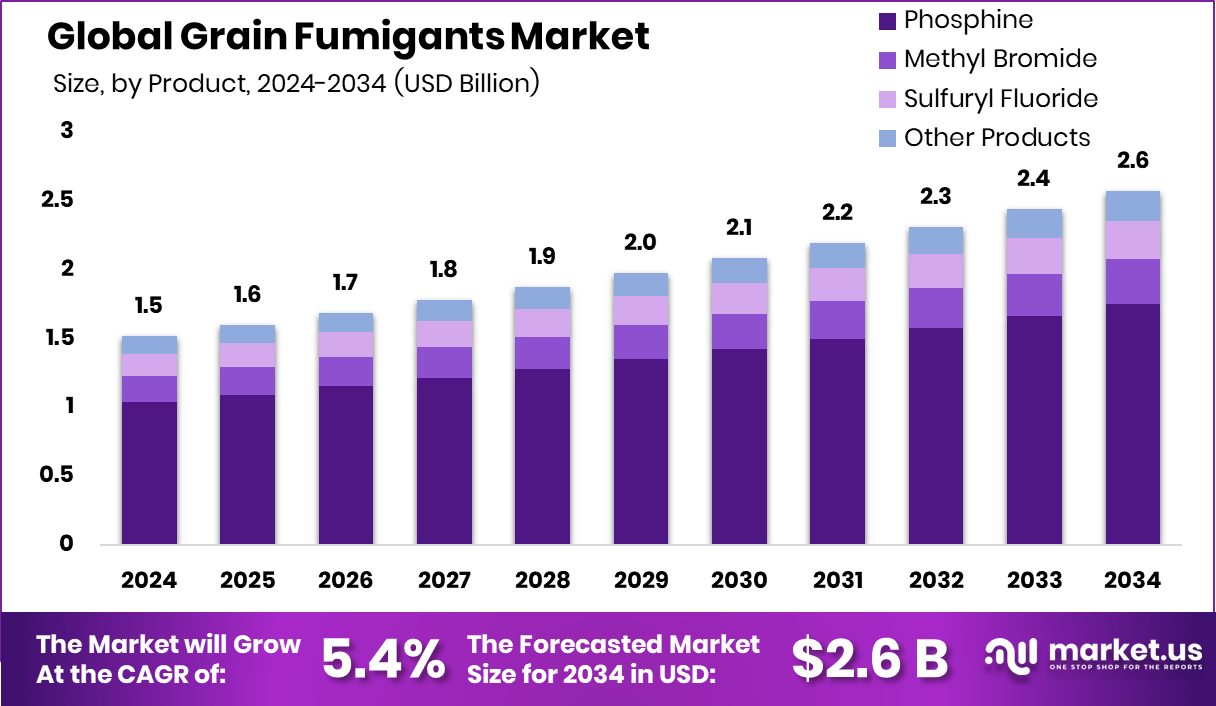

New York, NY – September 24, 2025 – The Global Grain Fumigants Market was valued at approximately USD 1.5 billion. The market is projected to grow at a CAGR of 5.4% between 2025 and 2034, reaching an estimated USD 2.6 billion by 2034.

Grain fumigants are gaseous pesticides applied to stored grains to control insects and other pests. They effectively penetrate grain masses, targeting pests at all life stages. Fumigation plays a critical role in agriculture by preserving grain quality and minimizing economic losses due to pest infestations.

Phosphine-based fumigants are the most widely used in solid form, particularly in warehouse storage. The primary driver of market growth is the increasing global grain consumption, which necessitates reducing losses during storage and transportation. However, the hazardous nature of fumigants has led to strict regulations and significant investments in research and development. While regulatory restrictions and pest resistance may limit market growth, bio-based fumigants are gaining traction.

Additionally, integrating fumigants into broader pest management strategies is an emerging trend. Food loss remains a significant global challenge, with an estimated 2.5 billion tons of food going uneaten annually. Studies indicate that approximately 1.3 billion tons of food are lost on farms worldwide during and after harvest, representing roughly 15% of total food production. This underscores the importance of effective grain preservation strategies, including fumigation.

Key Takeaways

- The Global Grain Fumigants Market was valued at USD 1.52 billion in 2024, at a CAGR of 5.4% and is estimated to reach USD 2.6 billion by 2034.

- Phosphine-based grain fumigants dominate the market with around 68.2% of the total market share.

- Solid grain fumigants held the majority of revenue share in 2024 at 38.4%.

- The grain fumigants market was led by warehouse fumigants with a substantial market share of 62.7% in 2024.

- The Asia Pacific was the biggest market for grain fumigants, constituting around 41.1% of the total market share, valued at approximately US$624 million.

➤ Curious about the content? Explore a sample copy of this report – https://market.us/report/grain-fumigants-market/request-sample/

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2024) | USD 1.5 Billion |

| Forecast Revenue (2034) | USD 2.6 Billion |

| CAGR (2025-2034) | 5.4% |

| Segments Covered | By Product Type (Phosphine, Methyl Bromide, Sulfuryl Fluoride, Other Products), By Form (Solid, Liquid, Gas), By Application (Commercial Grain Elevators, On-farm Silos, Shipping Containers, and Barges, Warehouse and Transit Storage) |

| Competitive Landscape | Douglas Products, Arkema Group, AMVAC Chemical Corporation, LANXESS, Trinity Manufacturing, Inc., UPL Ltd., Detia-Degesch Group, National Fumigants Pty Ltd., Jining Shengcheng Chemical Experimental Co., Ltd., Other Key Players. |

➤ Directly purchase a copy of the report – https://market.us/purchase-report/?report_id=157181

Key Market Segments

Product Type Insights

Phosphine-based fumigants led the grain fumigants market in 2024, holding a commanding 68.2% share, with a market value of USD 954 million. Their dominance stems from high efficacy against a wide range of stored product pests, including insects, mites, and rodents.

Phosphine is cost-effective, requires minimal equipment for application, and is versatile for use in various storage facilities such as silos, bins, warehouses, railcars, ships, and containers. Additionally, it degrades rapidly into harmless phosphorous oxides, minimizing environmental residue, as noted by the National Institutes of Health (NIH).

Form Analysis

Solid grain fumigants captured a 38.4% market share in 2024, driven by their efficiency and ease of storage. Granular solid formulations are simpler to handle and apply using standard equipment like spreaders, reducing drift compared to liquid mists or dusts. This lowers the risk of applicator exposure and environmental contamination. Solid fumigants release active gas steadily over time, offering consistent pest control. They are also safer to handle than concentrated liquids or compressed gases, with reduced risks of spillage or accidental high-concentration releases.

Application Insights

Warehouse storage applications dominated the market in 2024, accounting for 62.7% of the total market share. Fumigants excel in warehouse and soil applications due to their ability to penetrate stored products like grains, fruits, and vegetables, effectively targeting hidden pests. Their capacity to treat entire storage volumes in a single application saves time and labor, making them ideal for grain storage and transportation.

Regional Analysis

In 2024, the Asia Pacific region led the global grain fumigants market, capturing a 41.1% share valued at approximately USD 624 million. With nearly half the world’s population, the region’s high demand for food security drives significant use of grain fumigants. For example, China’s grain production reached 706.5 million tons in 2024, up 1.6% from 2023, while India produced around 332.3 million metric tons, according to India’s Ministry of Agriculture and Farmers Welfare.

The region’s tropical climate fosters post-harvest pest and fungal issues, prompting widespread fumigant use to maintain crop quality during storage. Additionally, expanding storage infrastructure and growing food grain exports further boost demand. Notably, the Food Corporation of India (FCI) has advanced a public-private partnership to develop 2.5 million tons of modern wheat storage facilities.

Top Use Cases

- Stored Grain Protection in Silos: Grain fumigants like phosphine gas are applied in sealed silos to eliminate insects at every life stage, from eggs to adults, ensuring the grain stays clean and healthy during long-term storage. This method penetrates deep into bulk piles, preventing damage that could spoil the crop and lead to big losses for farmers and handlers. It supports a steady supply for food markets by keeping quality high without constant checks.

- Fumigation of Bagged Grain Stacks: In warehouses, fumigants are released under tarpaulin sheets covering stacked bags of grain, allowing the gas to seep through and kill hidden pests quickly. This approach is ideal for large collections of bagged cereals or pulses, saving time and effort compared to manual treatments. It helps maintain freshness and value, especially in busy trade hubs where space is tight and quick turnaround matters.

- Pest Control During Grain Transportation: Fumigants treat grains loaded into ships, trucks, or railcars before long journeys, stopping insects from spreading across borders and causing quarantine issues. The gas fills the cargo hold evenly, targeting infestations that could start en route due to warmth or movement. This keeps international shipments safe and compliant, boosting trust in global food trade networks.

- Warehouse Bulk Storage Treatment: For open-top or bolted steel bins in commercial warehouses, fumigants are circulated through fans to reach every corner and eliminate rodents or bugs burrowing in loose grain masses. This closed-loop system ensures even coverage without leaks, protecting against resistance buildup in pests. It’s a go-to for elevators handling mixed loads, helping avoid downtime from repeated cleanups.

- Spot Fumigation in On-Farm Bins: Small-scale farmers use liquid or solid fumigants for quick treatments in farm bins where pests show up early after harvest, applying them directly to hotspots without full enclosure. This targeted method cuts down on chemical use while stopping small problems from growing into major ones. It fits busy rural routines, preserving home-grown yields for local sales or family needs.

Recent Developments

1. Douglas Products

Douglas Products continues to advance its proprietary ECOTERIC brand of phosphine fumigants. Recent developments focus on formulations that generate phosphine gas more rapidly and uniformly, improving efficacy and shortening treatment times in bulk grain storage. This addresses the critical need for speed and reliability in pest control logistics. The company also emphasizes its commitment to sustainable and worker-safe application practices through advanced delivery systems.

2. Arkema Group

While not a direct fumigant manufacturer, Arkema is a key supplier of critical raw materials. A significant recent development is its investment in increasing production capacity for sulfur derivatives, which are essential for sulfuryl fluoride-based fumigants. This expansion supports the growing demand for this non-flammable, non-corrosive alternative to methyl bromide and phosphine, ensuring a stable supply chain for fumigant producers and helping to control costs in the market.

3. AMVAC Chemical Corporation

AMVAC has been actively integrating the Schumann Fumigant business, acquired in 2021, to strengthen its position in the grain fumigant market. A key recent focus is on the commercial expansion of its patented SOVERIGN technology, a liquid phosphine formulation. This product is designed for faster gas release and superior penetration in sealed structures, offering a modern solution for rapid disinfestation of stored grain pests with improved handling.

4. LANXESS

LANXESS focuses on innovative application technologies for its phosphine-based fumigants. A major recent development is the promotion and refinement of its PHOSTOXIN product line with specialized application equipment. The company emphasizes “Closed-Loop Fumigation” systems, which recirculate phosphine gas within silos. This technology enhances safety by minimizing human exposure, improves efficacy by ensuring even gas distribution, and aligns with stringent environmental and workplace safety regulations.

5. Trinity Manufacturing, Inc.

Trinity Manufacturing’s recent developments are centered on the equipment side of fumigation. The company has advanced its application and monitoring technology, particularly for phosphine fumigations. This includes refining its patented Curmin system and other recirculation units that automate the process of introducing and distributing fumigants within grain bins. This technology ensures precise dosage, improves operator safety by reducing exposure, and is critical for achieving complete pest control in large-scale storage facilities.

Conclusion

Grain Fumigants as a vital tool in today’s fast-paced agriculture world, where keeping food safe from pests drives everything from farm gates to dinner tables. With more people around the globe needing reliable supplies, these treatments shine by cutting waste and upholding quality without heavy environmental strain. Emerging shifts toward greener options and smarter tech promise even better ways to blend safety with sustainability, opening doors for steady growth and fresh ideas that benefit everyone in the chain.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)