Table of Contents

Overview

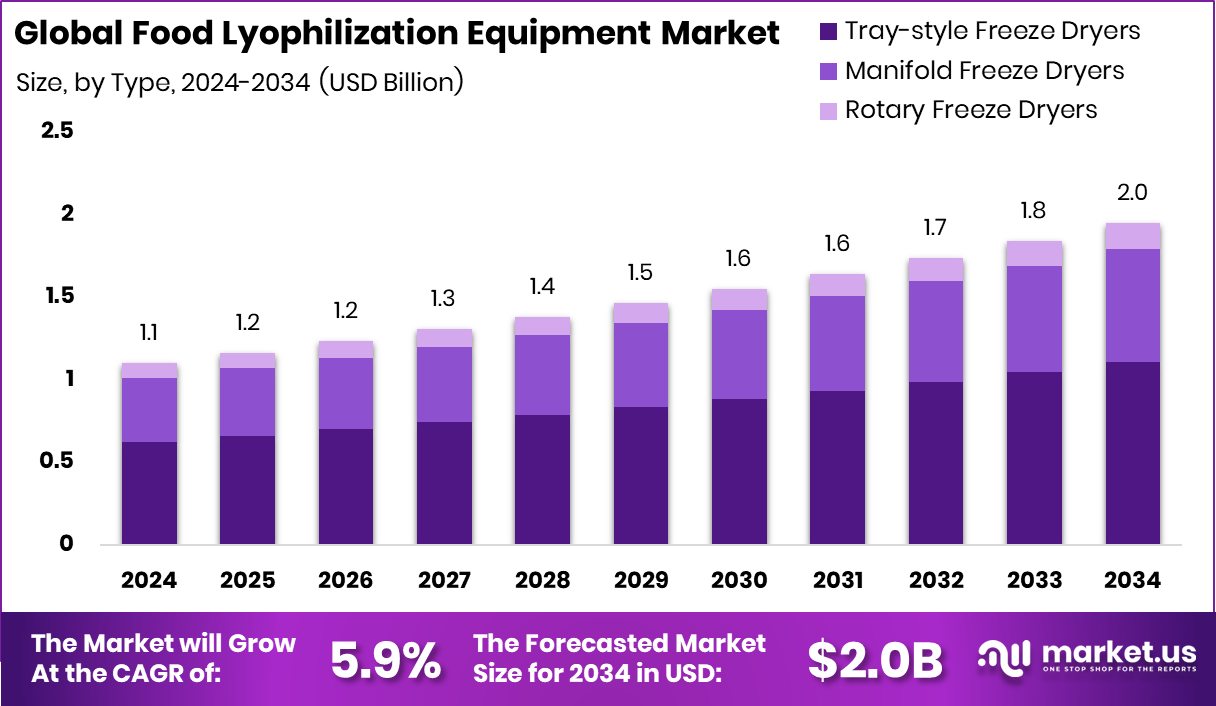

The Food Lyophilization Equipment Market, valued at USD 1.1 billion in 2024, is projected to reach USD 2.0 billion by 2034, registering a 5.9% CAGR from 2025–2034. Asia Pacific leads the market with a 47.80% share, accounting for USD 0.5 billion, supported by strong food processing expansion and rising demand for nutrient-stable ingredients.

Lyophilization equipment—used to freeze-dry food under low-temperature, vacuum conditions—plays a critical role in preserving taste, structure, and nutrition without additives. Its adoption is accelerating across fruits, vegetables, dairy inputs, probiotics, and functional foods as manufacturers prioritize clean-label and long-shelf-life formulations.

A key driver behind market growth is the surge in probiotic and microbiome research, where moisture-sensitive ingredients require highly stable drying technologies. Significant funding reflects this momentum: BiomEdit’s USD 18.4M Series B, Ostia Sciences’ USD 1.46M seed round, and £1.8M dedicated to probiotics research.

Commercial scaling in gut-health solutions further strengthens equipment demand, marked by Sun Genomics’ USD 8.65M Series A, Seed Health’s USD 40M Series A, and General Mills’ USD 12M investment in GoodBelly Probiotics. Additionally, larger rounds—Evolve’s USD 55M Series D and Pendulum Therapeutics’ USD 54M Series C—underscore long-term reliance on freeze-drying systems for both clinical-grade and consumer nutrition products.

Top Key Players in the Market

- GEA Group Aktiengesellschaft

- Hosokawa Micron Powder Systems

- Tofflon Science and Technology Group Co., Ltd.

- Martin Christ Gefriertrocknungsanlagen GmbH

- Spincotech

- Cuddon Freeze Dry

- LOBOAO

- SED Pharma

- Kemolo

- Frozen in Time, Ltd.

1. GEA Group Aktiengesellschaft

GEA Group is a global process technology leader specializing in food processing and freeze-drying systems. The company offers highly engineered lyophilization solutions for dairy, beverages, nutrition, and specialty food sectors. Its freeze-drying systems are known for efficiency, automation, and hygiene design. GEA’s solutions support large-scale food preservation and ingredient stabilization worldwide.

The company operates across multiple continents, providing turnkey systems and integrated digital monitoring tools that help food processors improve quality and reduce energy consumption. GEA continues to expand its thermal processing, refrigeration, and freeze-drying portfolio through innovation-led investments.

| Information Type | Official Website Data |

|---|---|

| Company Name | GEA Group Aktiengesellschaft |

| Headquarters | Düsseldorf, Germany |

| CEO | Stefan Klebert |

| Founded | 1881 |

| Industry | Process Engineering & Technology |

| Key Products | Freeze dryers, process systems, food technology |

| Global Presence | 60+ countries |

| Employees | ~18,000 |

| 2023 Revenue | €5.38 billion |

| Stock Listing | Frankfurt Stock Exchange |

| Official Website | https://www.gea.com |

2. Hosokawa Micron Powder Systems

Hosokawa Micron Powder Systems specializes in powder processing technologies including drying, milling, and classification systems. The company develops freeze-drying and vacuum-drying solutions for food powders, ingredients, and nutraceutical materials where moisture control is critical.

The company supports clients with engineering services, testing facilities, and industrial-scale system installation. With a strong legacy in process engineering, Hosokawa remains a major supplier to global food, pharma, and chemical manufacturers.

| Information Type | Official Website Data |

|---|---|

| Company Name | Hosokawa Micron Powder Systems |

| Headquarters | Summit, New Jersey, USA |

| Parent Company | Hosokawa Micron Group |

| Industry | Powder Processing |

| Key Products | Drying systems, milling, mixers, classifiers |

| Food Solutions | Freeze-drying alternatives, vacuum drying |

| Global Presence | 10+ facilities |

| Testing Centers | Multiple R&D labs |

| Official Website | https://www.hosokawamicron.com |

3. Tofflon Science and Technology Group Co., Ltd.

Tofflon is one of the world’s largest providers of freeze-drying systems, serving food, biotech, and pharma industries. The company offers industrial-scale lyophilizers, automated loading systems, and intelligent drying technologies widely used in sensitive food ingredients. Its food freeze-drying division provides turnkey engineering solutions, integrating processing, drying, packaging, and automation.

| Information Type | Official Website Data |

|---|---|

| Company Name | Tofflon Science and Technology Group Co., Ltd. |

| Headquarters | Shanghai, China |

| Industry | Freeze-drying & Process Engineering |

| Key Products | Food & pharma freeze dryers |

| Global Presence | 40+ countries |

| Facilities | Multiple bases in China |

| Stock Listing | Shenzhen Stock Exchange |

| Official Website | https://www.tofflon.com |

4. Martin Christ Gefriertrocknungsanlagen GmbH

Martin Christ is a global leader in freeze-drying technology, offering laboratory, pilot, and production-scale systems. Its food freeze-drying solutions support high-purity drying for sensitive fruits, vegetables, probiotics, and functional ingredients. The company is known for innovation in vacuum control, digital monitoring, and energy-efficient drying chambers.

| Information Type | Official Website Data |

|---|---|

| Company Name | Martin Christ Gefriertrocknungsanlagen GmbH |

| Headquarters | Osterode am Harz, Germany |

| Founded | 1947 |

| Industry | Freeze-Drying Technology |

| Key Products | Lab & production freeze dryers |

| Customers | Food, biotech, pharma |

| Global Presence | 70+ countries |

| Official Website | https://www.martinchrist.de |

5. Spincotech

Spincotech manufactures freeze-drying and vacuum-drying solutions used in food and ingredient processing. The company focuses on engineering reliability, energy efficiency, and long-term operational performance.

Its food solutions support fruits, vegetables, herbs, nutraceuticals, and instant food powders requiring moisture reduction without thermal damage.

| Information Type | Official Website Data |

|---|---|

| Company Name | Spincotech |

| Headquarters | Gujarat, India |

| Industry | Drying & Process Equipment |

| Key Products | Freeze dryers, vacuum dryers |

| Applications | Food, pharma, herbal powders |

| Services | Installation & maintenance |

| Official Website | https://www.spincotech.com |

6. Cuddon Freeze Dry

Cuddon Freeze Dry is one of the world’s longest-standing freeze-dryer manufacturers, offering food-grade systems for vegetables, meat, dairy, and specialty nutrition products. The company designs industrial-scale freeze-dryers with advanced vacuum systems.

Its systems are widely used in premium ingredient manufacturing requiring long shelf life and preservation of nutrition.

| Information Type | Official Website Data |

|---|---|

| Company Name | Cuddon Freeze Dry |

| Headquarters | Blenheim, New Zealand |

| Founded | 1935 |

| Industry | Freeze-Drying Technology |

| Key Products | Industrial freeze dryers |

| Markets | Food, biotech, agriculture |

| Official Website | https://www.cuddon.co.nz |

7. LOBOAO

LOBOAO manufactures pilot-scale and industrial freeze-dryers for food ingredient processing, specializing in customized drying chambers and automation integration.

The company supplies drying systems for fruit powders, herbal foods, dairy ingredients, and plant-based products.

| Information Type | Official Website Data |

|---|---|

| Company Name | LOBOAO |

| Headquarters | Henan, China |

| Industry | Freeze Dryer Manufacturing |

| Key Products | Freeze dryers, vacuum dryers |

| Applications | Fruits, vegetables, herbs |

| Official Website | https://www.loboao.com |

8. SED Pharma

SED develops processing, drying, and packaging systems serving food, herbal, nutraceutical, and pharmaceutical industries. Their freeze-dryers support precise moisture removal for sensitive ingredients.The company provides turnkey engineering services with global equipment distribution.

| Information Type | Official Website Data |

|---|---|

| Company Name | SED Pharma / SED Industry |

| Headquarters | Zhejiang, China |

| Industry | Processing & Drying Equipment |

| Key Products | Freeze dryers, vacuum dryers |

| Solutions | Food & nutraceutical processing |

| Official Website | https://www.sedpharma.com |

9. Kemolo

Kemolo manufactures industrial-scale freeze-dryers for fruits, vegetables, dairy, plant foods, and probiotics. Its systems are exported globally and known for energy efficiency and automation. The company specializes in large freeze-drying chambers with PLC-based controls.

| Information Type | Official Website Data |

|---|---|

| Company Name | Kemolo |

| Headquarters | Shanghai & Nanjing, China |

| Industry | Freeze-Drying Systems |

| Key Products | Industrial freeze dryers |

| Export Regions | 40+ countries |

| Applications | Food ingredients, nutritional powders |

| Official Website | https://www.kemolo.com |

10. Frozen in Time Ltd.

Frozen in Time supplies freeze-dryers and vacuum dryers for food, coffee, nutraceutical, and specialty ingredient producers. Their equipment is used globally for small and medium-scale production. The company provides full engineering, installation, and servicing solutions.

| Information Type | Official Website Data |

|---|---|

| Company Name | Frozen in Time Ltd. |

| Headquarters | Yorkshire, United Kingdom |

| Industry | Freeze-Drying Equipment |

| Key Products | Freeze dryers & vacuum dryers |

| Markets Served | Food, nutrition, pharma |

| Official Website | https://www.frozenintime.co.uk |

Conculsion

The Food Lyophilization Equipment market is moving steadily toward wider adoption as food manufacturers prioritize clean-label ingredients, longer shelf life, and protection of sensitive nutrients. Freeze-drying continues to gain relevance across fruits, vegetables, probiotics, dairy components, and functional foods because it maintains natural quality without additives. Investments in gut-health innovation and advanced nutrition further strengthen the need for reliable, high-precision drying systems. As technology improves in automation, energy efficiency, and process control, manufacturers increasingly view lyophilization as a long-term strategic tool that supports premium product development and global food stability.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)