Table of Contents

Overview

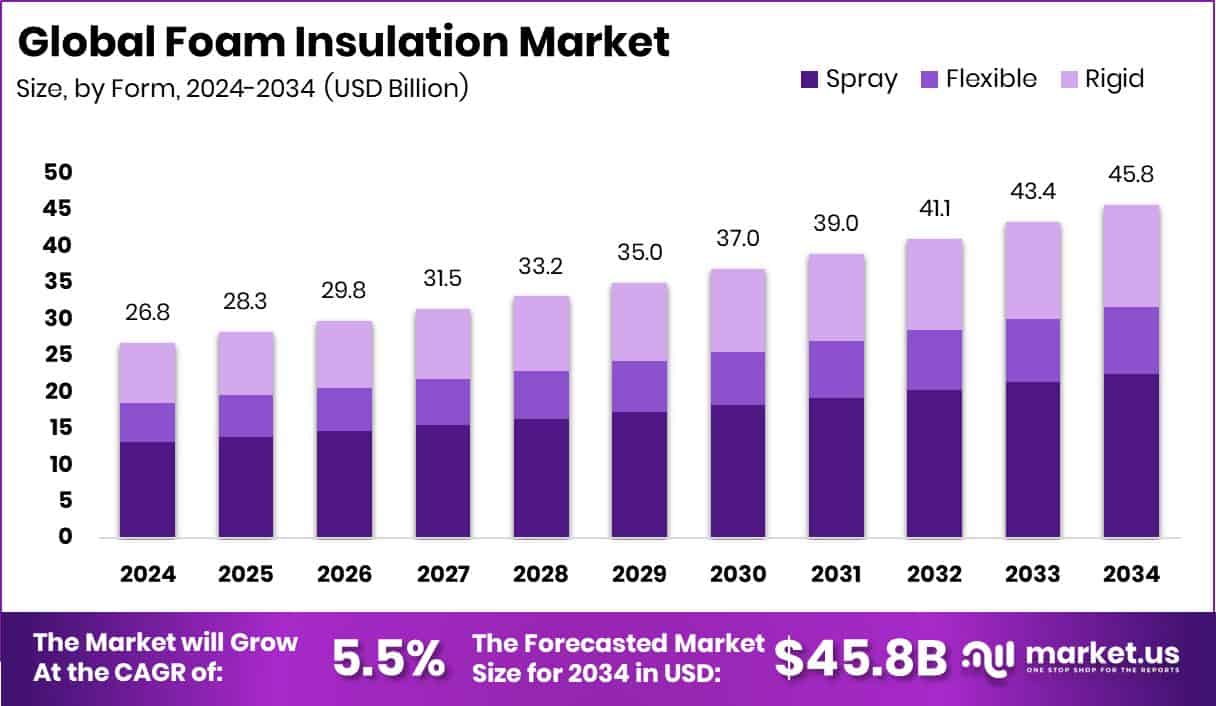

New York, NY – October 23, 2025 – The global foam insulation market is on a strong growth trajectory, expected to rise from USD 26.8 billion in 2024 to around USD 45.8 billion by 2034, representing a projected CAGR of 5.5% over the 2025–2034 period. At present, the foam insulation sector alone is valued at roughly USD 12.2 billion, underscoring its dominant role in the insulation industry.

Foam insulation works by expanding into gaps and crevices in walls, roofs, and floors to form an effective barrier against heat, cold, and noise, setting it apart from traditional materials by sealing the structure comprehensively and improving energy efficiency. Its versatility and durability make it increasingly popular across both residential and commercial construction.

Several tailwinds are driving the market forward. Firstly, energy conservation is becoming a global imperative, and stricter building codes along with heightened consumer awareness of sustainable living are pushing demand for high-performance insulation. Secondly, urbanization, rising energy costs, and expansion of construction activity—especially in developing regions—are all accelerating uptake. Renovation trends also play a role, with homeowners upgrading insulation to enhance comfort and cut long-term costs.

Investment flow into the sector emphasises its strength: a bio-based polyurethane company secured USD 5 million in funding, signalling confidence in eco-friendly insulation alternatives. Meanwhile, in India, Sheela Foam raised ₹1,200 crore via a QIP, and its stock jumped around 4%, highlighting strong capital interest in this space.

Looking ahead, a major growth opportunity lies in the development of bio-based and recyclable foam insulation products. As environmental concerns intensify, companies that invest in greener technologies stand to gain both regulatory favour and consumer preference in the competitive insulation market.

➤ Click the sample report link for complete industry insights: https://market.us/report/global-foam-insulation-market/request-sample/

Key Takeaways

- The Global Foam Insulation Market is expected to be worth around USD 45.8 billion by 2034, up from USD 26.8 billion in 2024, and is projected to grow at a CAGR of 5.5% from 2025 to 2034.

- By Form, spray foam dominates with 49.4%, offering excellent air sealing and energy efficiency.

- By Product, polyurethane foam leads with 38.3%, favored for durability, insulation strength, and versatile applications.

- By End Use, building and construction accounts for 45.8%, driven by rising housing and infrastructure projects.

- Asia Pacific’s growth reflects rising construction activity and demand for energy efficiency.

➤ Directly purchase a copy of the report – https://market.us/purchase-report/?report_id=160100

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2024) | USD 26.8 Billion |

| Forecast Revenue (2034) | USD 45.8 Billion |

| CAGR (2025-2034) | 5.5% |

| Segments Covered | By Form (Spray, Flexible, Rigid), By Product (Polyurethane Foam, Polystyrene Foam, Polyolefin Foam, Phenolic Foam, Elastomeric Foam, Others), By End Use (Building and Construction, Automotive and Transportation, Electricals and Electronics, Packaging, Others) |

| Competitive Landscape | Air Barrier Association of America, Armacell International, BASF, Carlisle Companies, Covestro, Dow Chemical, Huntsman Building Materials, Johns Manville, Kingspan Group |

Key Market Segments

By Form Analysis

In 2024, Spray Foam dominated the By Form segment of the Foam Insulation Market, holding a 49.4% share. Its popularity stems from its ability to expand and seal even the smallest gaps, delivering exceptional thermal performance and reducing air leakage. This efficiency makes it superior to many traditional insulation types. The ease of application in both new construction and renovation projects has significantly boosted its demand.

Rising emphasis on energy-efficient buildings and the need to cut heating and cooling costs have also fueled its adoption. Builders and homeowners increasingly prefer spray foam for its versatility, durability, and long-term savings. As sustainability goals and energy regulations tighten globally, spray foam insulation remains a key driver of market expansion, reaffirming its dominant role in shaping the future of energy-efficient construction practices.

By Product Analysis

In 2024, Polyurethane Foam dominated the by-product segment of the foam insulation market, capturing a 38.3% share. Its leadership is driven by outstanding thermal resistance, lightweight properties, and the ability to form an airtight seal, significantly enhancing building energy efficiency. The material’s versatility across residential, commercial, and industrial sectors has made it a preferred insulation solution where both performance and durability are essential. Its ease of application and compatibility with diverse construction designs further boost its adoption.

With the global construction industry increasingly prioritizing energy conservation and sustainable building standards, polyurethane foam remains a key contributor to lowering energy consumption and reducing carbon footprints. These advantages continue to solidify its dominance in the foam insulation product category, reflecting its vital role in advancing energy-efficient and eco-conscious construction practices worldwide.

By End Use Analysis

In 2024, Building and Construction dominated the By End Use segment of the Foam Insulation Market, accounting for a 45.8% share. This leadership reflects the growing emphasis on energy-efficient infrastructure and compliance with stricter building regulations focused on reducing energy consumption.

Foam insulation is extensively applied in walls, roofs, and flooring to enhance thermal performance and minimize utility expenses, making it a critical component in modern construction. Rapid urbanization and expanding infrastructure projects across developing and developed regions have accelerated its adoption in both residential and commercial buildings.

With homeowners and builders prioritizing sustainability, comfort, and long-term cost savings, foam insulation continues to play a vital role in shaping energy-smart construction practices. Its combination of durability, efficiency, and regulatory compliance reinforces its dominance and ensures continued demand in the evolving global building and construction landscape.

Regional Analysis

In 2024, Asia Pacific dominated the Foam Insulation Market, capturing a 45.80% share valued at USD 12.2 billion. This leadership stems from rapid urbanization, extensive infrastructure development, and strong demand for energy-efficient construction materials across major economies like China, India, and Japan. The region’s focus on sustainable housing and government-backed energy-saving initiatives continues to strengthen its position.

North America remains a key market, supported by the adoption of advanced insulation technologies and a growing emphasis on energy conservation in homes and commercial buildings. Europe follows closely, driven by stringent energy regulations and sustainability commitments within the construction sector.

Meanwhile, the Middle East & Africa region shows steady progress through infrastructure investments and adaptation to harsh climatic conditions, while Latin America experiences growth from rising construction activity and awareness of long-term energy cost benefits.

Top Use Cases

- Sealing hard-to-reach spaces: Foam insulation (especially spray polyurethane foam) is ideal for filling gaps around wires, pipes, corners, and other difficult spots where standard insulation fails. It expands and forms a tight seal, helping to prevent air leakage and improve insulation.

- Roof and attic insulation for energy savings: By installing foam insulation under roof decks or in attics, homes can reduce heat loss or gain through the top of the building. This improves indoor comfort and can cut heating/cooling bills over time.

- Creating a combined air barrier + thermal barrier: Some foam insulation types act both as insulation material and as an air-tight barrier. This means they reduce heat transfer and prevent drafts or moisture from moving through the structure, making them very effective.

- Retrofitting existing buildings for better performance: Foam board insulation (rigid foam panels) is used in retrofit projects to upgrade older homes or buildings. It helps improve insulation value and seal continuous surfaces, making older structures more energy efficient.

- Reducing moisture and mold risk: Because some foam insulation types can act as vapor or moisture barriers (especially closed-cell foams), they help keep building cavities dry, which reduces the risk of mold growth or moisture damage.

- Enhancing structural strength and thermal envelope: Beyond just insulation, spray foam can bond to surfaces and fill voids, contributing to the overall integrity of the building envelope (walls, roof, floor). This can lead to improved durability and better long-term building performance.

Recent Developments

- In July 2025, Covestro launched its new “Baysafe® BEF” flame-retardant encapsulation polyurethane foam series aimed at EV battery applications. While not strictly “building insulation,” this foam tech highlights Covestro’s innovation in foam materials with high safety and performance demands.

- In January 2024, BASF partners with Carlisle Construction Materials to explore the use of Lupranate ZERO, a zero‐carbon-footprint isocyanate, in rigid foam boards and polyiso insulation. This effort targets building insulation with lower emissions using the same performance materials.

- In October 2024, Carlisle announced the acquisition of Plasti‑Fab, a Canadian-based maker of expanded polystyrene (EPS) insulation products (brands Plasti-Fab & Insulspan). The deal strengthens Carlisle’s EPS insulation business across Canada and the U.S. Midwest.

Conclusion

The Foam Insulation Market continues to expand as global focus on energy efficiency and sustainable construction grows stronger. Increasing demand for eco-friendly materials, coupled with advancements in insulation technologies, is transforming how buildings are designed for comfort and performance. Foam insulation’s ability to reduce heat loss, improve air sealing, and enhance indoor environments makes it a key solution for modern architecture.

Rising renovation projects and stricter building codes further accelerate adoption across residential, commercial, and industrial applications. With continuous innovation and growing environmental awareness, foam insulation is set to remain an essential component of energy-efficient and sustainable building practices worldwide.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)