Overview

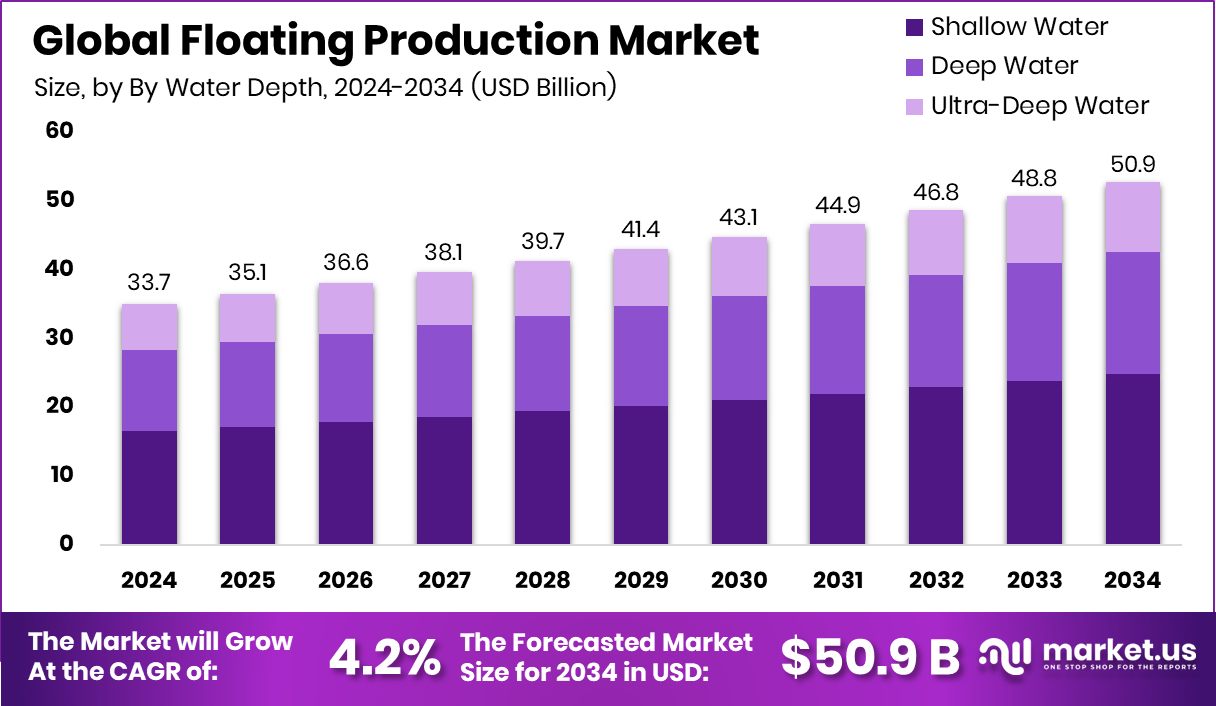

The global floating production market is on a steady growth path, supported by sustained offshore oil and gas development. The market is projected to expand from USD 33.7 billion in 2024 to around USD 50.9 billion by 2034, growing at a CAGR of 4.2% between 2025 and 2034. North America remains the leading region, accounting for 44.20% of the global market and reaching a current valuation of approximately USD 14.8 billion, driven by active deepwater projects and mature offshore infrastructure.

Floating production systems are offshore units that process oil and gas directly at sea. These systems receive hydrocarbons from subsea wells, separate oil, gas, and water onboard, and store or offload production without depending on fixed platforms or onshore facilities. They are especially critical for deepwater and ultra-deepwater fields where traditional infrastructure is technically complex or economically unviable.

Market momentum is strongly supported by capital investment. Around USD 126 billion is expected to be invested in floating production units by 2030, reflecting long-term industry confidence. Additionally, the U.S. decision to withdraw a USD 13 billion green-energy funding commitment has redirected capital toward conventional offshore energy assets.

Investor interest remains strong. A USD 1 billion new investment, tied to an FPSO company planning an initial public offering, highlights the growing financial appetite. Similarly, SBM Offshore’s USD 400 million FPSO contract and Yinson Production’s USD 1 billion financing round underline expanding opportunities for growth, refinancing, and global deployment of floating production assets.

Top Key Players in the Market

- Bumi Armada Berhad

- Hyundai Heavy Industries Co. Ltd

- Keppel Offshore & Marine Ltd

- Malaysia Marine and Heavy Engineering Berhad

- Mitsubishi Heavy Industries Ltd

- SBM Offshore

- TechnipFMC Plc

- Others

1. Bumi Armada Berhad

Bumi Armada Berhad is a Malaysia-headquartered offshore energy facilities and services provider with a strong footprint in floating production. The company supports offshore oil and gas developments through FPSO ownership/operations, offshore support vessels, and related marine services, helping operators bring fields online without fixed platforms. Its portfolio typically spans engineering support, deployment, and long-term operations across multiple basins.

The group’s strength is its integrated approach—combining floating production assets with marine and offshore services to support field life-cycle needs. This positioning is relevant where operators need flexible capacity, reduced upfront infrastructure, and reliable offshore execution across deepwater and mature assets.

| Item | Details |

|---|---|

| Company | Bumi Armada Berhad |

| CEO | Gary Neal Christenson |

| Headquarters | Kuala Lumpur, Malaysia |

| Core Offering | FPSO; offshore marine services |

| Key Solutions | Floating production operations; vessel support |

| Business Model | Asset operations + marine services |

| Primary Customers | Offshore oil & gas operators |

| Geographic Reach | Multi-region offshore markets |

| Website | bumiarmada.com |

| Public Listing | Bursa Malaysia (group listed) |

| Industry | Offshore energy services |

| Notable Capability | FPSO operations and lifecycle support |

2. HD Hyundai Heavy Industries Co. Ltd

HD Hyundai Heavy Industries is a major shipbuilding and offshore engineering company headquartered in Ulsan, South Korea. It builds commercial vessels and delivers offshore engineering capabilities that support energy infrastructure at sea, including offshore structures and complex marine equipment. Its scale and manufacturing depth make it a key supplier for global maritime and offshore project requirements.

Alongside shipbuilding, the company’s industrial base supports broader marine technology needs through engines, machinery, and engineering services. This combination helps customers source integrated solutions for ship construction and offshore development, backed by extensive production facilities and engineering know-how.

| Item | Details |

|---|---|

| Company | HD Hyundai Heavy Industries Co. Ltd |

| Headquarters | Ulsan, South Korea |

| Core Businesses | Shipbuilding; offshore engineering; engines & machinery |

| Products | Ships; offshore structures; marine equipment |

| Customer Base | Global shipowners; offshore energy developers |

| Operational Strength | Large-scale manufacturing + engineering |

| Industry | Marine & offshore industrials |

| Primary Value | End-to-end build capability |

| Technology Focus | Advanced ship and offshore engineering |

| Global Footprint | International project delivery |

| Brand Group | HD Hyundai |

| Website | hhi.co.kr |

3. Keppel Offshore & Marine (Keppel)

Keppel’s offshore and marine capabilities are recognized for engineering and project execution supporting offshore energy development. Historically, Keppel’s O&M platform has contributed to offshore construction, conversions, and marine solutions that enable operators to develop and maintain offshore assets efficiently. Its broader group strategy increasingly emphasizes sustainable infrastructure and energy transition-aligned solutions.

Keppel’s value proposition has been built around complex offshore engineering delivery, lifecycle support, and partnerships that enable large offshore programs. Where applicable, its offshore experience supports floating production-related engineering, conversions, and specialist marine work that reduces time-to-deployment for offshore projects.

| Item | Details |

|---|---|

| Company | Keppel (Offshore & Marine platform) |

| Group | Keppel Ltd |

| Headquarters | Singapore |

| Group CEO | Loh Chin Hua |

| Core O&M Capabilities | Offshore engineering; marine solutions |

| Typical Services | Engineering; project execution; lifecycle support |

| Market Relevance | Offshore energy infrastructure |

| Positioning | Infrastructure + energy transition orientation |

| Customer Base | Offshore operators & contractors |

| Geographic Reach | Global operations |

| Website | keppel.com |

| Strength | Complex offshore execution heritage |

4. Malaysia Marine and Heavy Engineering Berhad (MHB)

Malaysia Marine and Heavy Engineering Berhad (MHB) provides marine repair, shipbuilding and heavy engineering solutions that support offshore and energy projects. Its capabilities span fabrication and offshore construction support, helping deliver critical structures and services for regional and international customers. MHB’s operating base in Malaysia supports multi-disciplinary delivery across marine and energy project requirements.

In offshore contexts, MHB’s engineering and yard capabilities are typically applied to construction, maintenance, and project execution work that supports asset owners and EPC contractors. This role is important for schedules and reliability in offshore developments, where timely fabrication and marine services reduce operational downtime and improve project delivery confidence.

| Item | Details |

|---|---|

| Company | Malaysia Marine and Heavy Engineering Berhad (MHB) |

| Headquarters | Malaysia |

| Industry | Marine & heavy engineering |

| Core Services | Marine repair; shipbuilding; heavy engineering |

| Offshore Relevance | Fabrication and construction support |

| Customer Base | Marine operators; offshore energy players |

| Capabilities | Yard-based engineering + execution |

| Value | Schedule support and reliability |

| Operating Base | Malaysia yards |

| Regional Strength | Asia-focused delivery |

| Website | mhb.com.my |

| Public Listing | Bursa Malaysia (company listed) |

5. Mitsubishi Heavy Industries, Ltd. (MHI)

Mitsubishi Heavy Industries (MHI) is a diversified engineering and manufacturing group with capabilities spanning energy, industry, logistics, aerospace and defense. Its engineering depth and large-project execution experience can support offshore and marine-adjacent requirements through industrial systems, machinery, and energy solutions, depending on project scope and geography.

For offshore value chains, MHI’s strengths typically sit in heavy engineering disciplines—advanced manufacturing, high-integrity equipment, and complex systems integration. This foundation helps customers seeking proven industrial partners capable of delivering reliable equipment and engineering solutions aligned with stringent safety and performance requirements in energy and marine environments.

| Item | Details |

|---|---|

| Company | Mitsubishi Heavy Industries, Ltd. |

| Headquarters | Japan |

| Industry | Heavy engineering & manufacturing |

| Core Segments | Energy; Industry; Logistics; Aerospace & Defense |

| Capabilities | Complex systems integration |

| Products | Industrial machinery & energy systems |

| Project Strength | Large-scale engineering delivery |

| Offshore Relevance | Heavy equipment and engineering support |

| Customer Base | Industrial and energy operators |

| Global Footprint | International operations |

| Website | mhi.com |

| Positioning | Technology-driven engineering group |

6. SBM Offshore

SBM Offshore is an offshore energy company known for floating production solutions and related lifecycle services. It supports offshore field development by delivering floating systems that process, store, and offload production, and it also provides long-term operations and maintenance support. This model helps operators reduce fixed infrastructure needs while enabling production from deepwater and remote areas.

SBM Offshore’s competitive strength is its end-to-end capability—covering design and execution through operations—along with experience delivering complex offshore projects. Its broader direction also includes innovation and efficiency improvements across floating energy infrastructure, relevant for customers balancing performance, cost discipline, and reliable offshore uptime.

| Item | Details |

|---|---|

| Company | SBM Offshore |

| CEO | Øivind Tangen |

| Headquarters | Netherlands |

| Industry | Offshore energy systems |

| Core Products | Floating production solutions (e.g., FPSO) |

| Core Services | Design; build; install; operate |

| Customer Base | Offshore oil & gas operators |

| Business Model | Project delivery + lifecycle operations |

| Offshore Focus | Deepwater and remote developments |

| Strength | End-to-end floating project execution |

| Website | sbmoffshore.com |

| Strategic Theme | Efficiency + innovation in floating infrastructure |

7. TechnipFMC plc

TechnipFMC is a global energy technology provider serving offshore and onshore projects with integrated capabilities across subsea and surface domains. It supports offshore production through subsea systems, installation, and lifecycle services, helping operators improve project execution and long-term asset performance. Its solutions are used across major offshore basins, supporting both traditional oil and gas developments and select energy transition pathways.

The company’s value lies in integrated project delivery—bringing engineering expertise, technology, and execution together to reduce interfaces and manage risk. With broad international operations and a strong technology base, TechnipFMC is positioned to support complex offshore developments where reliability, schedule performance, and lifecycle efficiency are key priorities.

| Item | Details |

|---|---|

| Company | TechnipFMC plc |

| CEO | Douglas J. Pferdehirt |

| Headquarters (Operational) | Houston, Texas, USA |

| Industry | Energy technology |

| Core Segments | Subsea; Surface Technologies |

| Products/Services | Subsea systems; installation; lifecycle services |

| Primary Customers | Energy operators and contractors |

| Global Presence | Multi-country operations |

| Value Proposition | Integrated delivery to reduce interfaces |

| Strength | Technology + execution at scale |

| Stock Listing | NYSE (company listed) |

| Website | technipfmc.com |

Conclusion

Floating production plays a vital role in modern offshore energy development by enabling oil and gas processing directly at sea. These systems offer flexibility, faster deployment, and adaptability across varying water depths and field conditions. By reducing dependence on fixed platforms and extensive onshore infrastructure, floating production supports efficient field development and extends the economic life of offshore assets.

It is especially valuable in deepwater and remote locations where traditional solutions are complex or impractical. As offshore operators continue to prioritize operational efficiency, risk management, and project flexibility, floating production remains a preferred solution. Its ability to integrate production, storage, and offloading positions it as a dependable backbone for long-term offshore energy operations.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)