Table of Contents

Overview

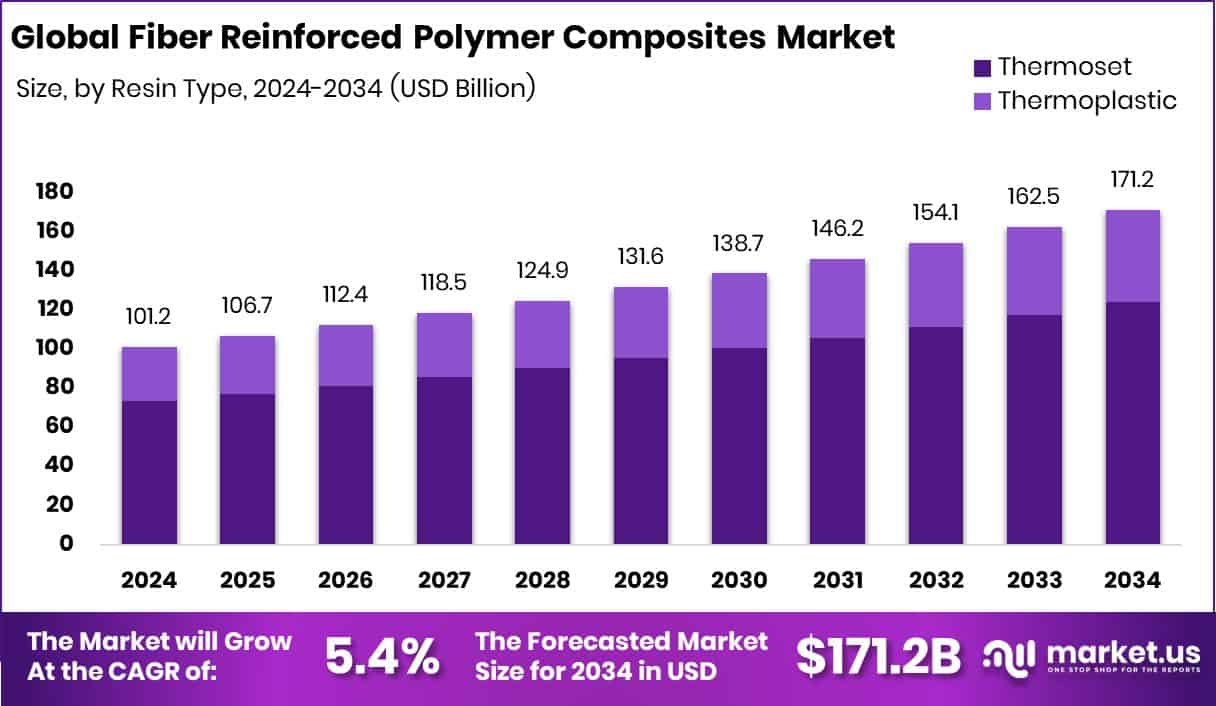

New York, NY – Nov 28, 2025 – The Global Fiber Reinforced Polymer (FRP) Composites Market is on a steady growth path, projected to rise from USD 101.2 billion in 2024 to around USD 171.2 billion by 2034, registering a 5.4% CAGR between 2025 and 2034. Asia-Pacific remains the central growth engine, accounting for 43.8% of activity and representing a future focus value of USD 44.3 billion, driven by infrastructure expansion, manufacturing scale, and transportation upgrades.

FRP composites combine high-strength fibers such as glass, carbon, aramid, or natural fibers with polymer matrices including epoxy, polyester, or vinyl ester. This combination delivers materials that are lightweight, corrosion-resistant, fatigue-tolerant, and adaptable to complex designs. As a result, FRP solutions are increasingly preferred in aerospace, automotive manufacturing, construction, marine systems, renewable energy, and performance equipment, where durability and reduced weight directly improve efficiency and lifecycle value.

Market momentum reflects broader shifts toward energy efficiency, modular construction, and circular material use. Sustainability is increasingly central, illustrated by Lignin Industries’ €3.9 million funding round to scale bio-based thermoplastics and Made of Air’s USD 5.8 million raise to advance carbon-negative materials. Infrastructure and innovation funding further support demand, with Spokane’s aerospace technology hub receiving USD 48 million, and Tacoma Fire securing USD 2.5 million to enhance durable equipment procurement.

Looking ahead, opportunities lie in combining FRP performance with bio-based chemistry, recycled inputs, automation, and low-carbon manufacturing. These advancements are expected to unlock broader adoption across public infrastructure and industrial applications while reshaping long-term cost and sustainability outcomes.

➤ Click the sample report link for complete industry insights: https://market.us/report/global-fiber-reinforced-polymer-composites-market/request-sample/

Key Takeaways

- The Global Fiber Reinforced Polymer Composites Market is expected to be worth around USD 171.2 billion by 2034, up from USD 101.2 billion in 2024, and is projected to grow at a CAGR of 5.4% from 2025 to 2034.

- In the Fiber Reinforced Polymer Composites Market, GFRP leads with 57.9% due to dominance and strength.

- Thermoset holds a 72.4% share, driving superior durability, heat resistance, and long-term performance across critical industries.

- Rovings command a 26.5% share, enabling continuous reinforcement for high-load structural composite parts with manufacturing efficiency.

- Automotive applications capture a 37.7% share, driven by lightweighting, fuel efficiency, safety focus, and global adoption.

- Asia-Pacific fiber composites reached USD 44.3 Bn, reflecting material adoption growth across industries.

➤ Directly purchase a copy of the report – https://market.us/purchase-report/?report_id=166171

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2024) | USD 101.2 Billion |

| Forecast Revenue (2034) | USD 171.2 Billion |

| CAGR (2025-2034) | 5.4% |

| Segments Covered | By Product Material (Glass Fiber Reinforced Polymer (GFRP) Composites, Carbon Fiber Reinforced Polymer (CFRP) Composites, Basalt Fiber Reinforced Polymer (BFRP) Composites, Aramid Fiber Reinforced Polymer (AFRP) Composites), By Resin Type (Thermoset, Thermoplastic), By Reinforcement Form (Rovings, Woven Fabrics and Mats, Chopped Strands, Prepreg, SMC and BMC), By Application (Automotive, Construction, Electronic, Defense, Others) |

| Competitive Landscape | Avient Corporation, Hexcel Corporation, Mitsubishi Chemical Group Corporation, Röchling SE & Co. KG, SABIC, SGL Carbon, Solvay, TORAY INDUSTRIES, INC., TPI Composites Inc. |

Key Market Segments

By Product Material Analysis

In 2024, Glass Fiber Reinforced Polymer (GFRP) composites led the By-Product Material segment of the Fiber Reinforced Polymer Composites Market, with a dominant 57.9% share, underscoring their widespread industrial acceptance. This strong position reflects continued reliance on GFRP across structural, industrial, and transportation applications where balanced strength, reliability, and cost efficiency remain critical selection factors.

The 57.9% share highlights GFRP’s versatility and compatibility with multiple polymer matrices, making it suitable for a broad range of composite designs. Its lightweight properties support engineering goals focused on durability, long service life, and reduced maintenance while maintaining consistent mechanical performance under operational stress. Additionally, GFRP’s stable reinforcement behavior allows manufacturers to produce molded, layered, and customized components with predictable quality and processing efficiency.

By Resin Type Analysis

In 2024, thermoset resins dominated the By Resin Type segment of the Fiber Reinforced Polymer Composites Market, securing a strong 72.4% share. This leadership highlights their continued preference for applications where dimensional stability, heat tolerance, and high structural bonding strength are essential for long-term performance.

The 72.4% share reflects consistent adoption of thermoset resins in molded composite products that depend on permanent cross-linked structures after curing. Such properties enable composites to maintain shape, strength, and reliability across varying thermal and mechanical conditions. This makes thermosets particularly suitable for demanding environments where performance consistency is critical.

Thermoset dominance also aligns with manufacturing processes that require controlled curing and predictable mechanical outcomes. Producers and engineering teams favor these resins for their proven processing stability and durable material behavior.

By Reinforcement Form Analysis

In 2024, rovings emerged as the leading reinforcement form in the By Reinforcement Form segment of the Fiber Reinforced Polymer Composites Market, capturing a 26.5% share. This position reflects their strong preference in composite manufacturing where continuous, uniform, and high-strength fiber reinforcement is required.

The 26.5% share highlights the importance of rovings in achieving consistent fiber distribution and reliable mechanical performance. Their continuous strand structure supports stable tensile strength and load-bearing capability, making them suitable for applications that demand structural uniformity. Rovings also integrate efficiently into composite processing methods where long fibers enhance material consistency and reduce variability.

By Application Analysis

In 2024, the automotive segment led the By Application category of the Fiber Reinforced Polymer Composites Market with a notable 37.7% share, confirming its position as the largest application area. This dominance reflects strong demand for composite materials in vehicle parts, body panels, and structural components, where reducing weight while maintaining durability is essential.

The 37.7% share highlights the automotive industry’s continued preference for advanced composite solutions that support lighter assemblies without sacrificing mechanical strength or design flexibility. FRP composites enable improved structural efficiency, helping manufacturers enhance handling performance and overall vehicle stability. Their consistent behavior under operational stress also supports long-term reliability across various vehicle systems.

Regional Analysis

In the regional landscape of the Fiber Reinforced Polymer Composites Market, Asia-Pacific stood as the leading region in 2024, capturing a dominant 43.8% share and reaching a value of USD 44.3 billion. This strong position reflects ongoing industrial expansion and growing reliance on lightweight, durable composite materials across manufacturing, construction, and engineered applications. The region’s leadership highlights how material efficiency and long-term structural performance align well with its rapidly scaling production capabilities.

The 43.8% share confirms consistent composite usage in applications that benefit from strength, durability, and reduced weight, supporting Asia-Pacific’s role as a key global manufacturing hub. Other regions, including North America, Europe, the Middle East & Africa, and Latin America, continue to contribute to overall market activity, driven by infrastructure upgrades and material innovation. However, based on the provided data, Asia-Pacific clearly remains the highest-performing region, leading both in percentage contribution and total market value within the global framework.

Top Use Cases

- Aerospace & Aviation Components: FRP composites are widely used in airplanes, drones, and other aircraft parts because they deliver high strength while being much lighter than traditional metal alloys. This weight reduction leads to better fuel efficiency, improved payload capacity, and easier handling — all critical in aviation.

- Automotive & Transport Structures: In the automotive sector, FRP composites replace metals in body panels, structural parts, and system components, enabling lighter vehicles that still maintain durability and safety.

- Marine & Shipbuilding — Boats, Hulls, Offshore Components: FRP composites are well-suited for boats, hulls, ship structures, and offshore installations because they resist seawater corrosion, reduce overall weight, and tolerate harsh environmental conditions better than many metals.

- Infrastructure & Bridge / Building Strengthening: In civil engineering, FRP materials are used to reinforce or repair existing structures — like concrete beams, columns or bridge decks — to improve load-bearing capacity, flexural strength, shear resistance, or ductility.

- Renewable Energy & Power Infrastructure — Wind Turbine Blades, Utility Components: FRP composites are increasingly used in wind turbine blades and energy-sector components because they offer a high strength-to-weight ratio and resistance to fatigue over long service life.

- Consumer Goods, Protective Equipment & Specialty Applications: FRP composites are also used in manufacturing consumer goods, sports and recreational equipment, protective gear, and specialized items — wherever a combination of lightweight design, strength, and durability is desired.

Recent Developments

- In March 2024, Mitsubishi Chemical unveiled the BiOpreg #400 Series — a carbon-fiber (and glass-fiber) prepreg using a plant-derived resin. The new prepreg includes up to ~25% biomass-based content while retaining the same molding performance, heat resistance, and toughness as conventional prepregs. The company aims to expand its use from sports and leisure into mobility (auto interiors/exteriors) and industrial applications

- In June 2024, Röchling Industrial — the division focused on technical plastics and composites — made a major push in composites despite a challenging market. The company invested over €74 million in property, plant, and equipment, including building a new Engineering Center in Lahnstein (Germany) and expanding facilities in Nancy (France). This investment supports the expansion of their composite product line.

Conclusion

The Fiber Reinforced Polymer Composites market represents a strong shift toward advanced, high-performance materials that meet modern industrial demands. Its growing adoption reflects the need for lightweight, durable, and corrosion-resistant solutions across transportation, construction, energy, and industrial applications.

Manufacturers value these composites for their design flexibility, long service life, and ability to replace traditional materials without compromising strength. Ongoing progress in sustainable resins, recycled fibers, and efficient manufacturing methods is further improving their appeal.

As industries continue to focus on performance, efficiency, and material innovation, fiber-reinforced polymer composites are expected to play an increasingly important role in shaping durable and future-ready engineering solutions.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)