Table of Contents

Overview

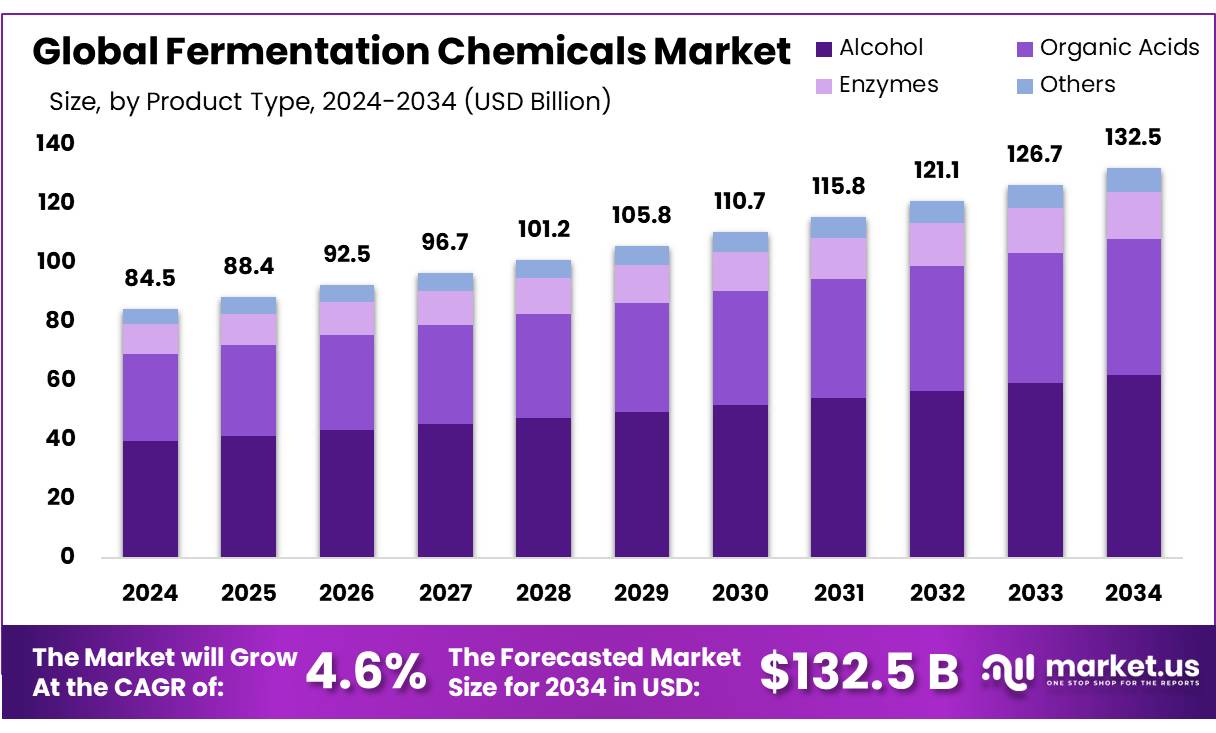

New York, NY – August 21, 2025 – The Global Fermentation Chemicals Market is projected to grow from USD 84.5 billion in 2024 to approximately USD 132.5 billion by 2034, achieving a CAGR of 4.6% during the forecast period from 2025 to 2034. In 2024, North America led the market, accounting for a 36.2% share with a revenue of USD 30.5 billion.

Fermentation chemicals are organic compounds generated through the metabolic process of fermentation, where microorganisms like yeast and bacteria convert carbohydrates into energy without oxygen. Key fermentation chemicals include ethanol, lactic acid, acetic acid, and carbon dioxide. These chemicals play a vital role in industries such as food & beverage and energy & fuel.

Ethanol is a critical ingredient in alcoholic beverages like beer and wine and is extensively used in the energy sector. In 2022, global ethanol production reached 28 billion gallons annually, with the United States and Brazil accounting for 80% of the output. Lactic acid, produced by bacteria, is essential for manufacturing fermented foods such as yogurt and sauerkraut. Additionally, enzymes derived from fermentation are widely used in pharmaceutical applications, including digestion and drug delivery processes.

Key Takeaways

- The Global Fermentation Chemicals Market was valued at USD 84.5 billion in 2024, at a CAGR of 4.6% and is estimated to reach USD 132.5 billion by 2034.

- In the product segment, alcohol dominates the market with around 46.8% of the total market share.

- Based on end-use industry, the market was led by the food & beverage industry with a substantial market share of 41.8% in 2024.

- In 2024, North America dominated the global fermentation chemicals market with a significant market share of 36.2%.

➤ Curious about the content? Explore a sample copy of this report – https://market.us/report/global-fermentation-chemicals-market/request-sample/

Report Scope

| Market Value (2024) | USD 84.5 Billion |

| Forecast Revenue (2034) | USD 132.5 Billion |

| CAGR (2025-2034) | 4.6% |

| Segments Covered | By Product Type (Alcohol, Organic Acids, Enzymes, Others), By End-Use Industry (Pharmaceuticals, Food and Beverages, Agriculture, Plastics & Fibres, Energy & Fuel, Other Industries) |

| Competitive Landscape | BASF SE, Amyris, Inc., DuPont Nutrition & Biosciences, Valero, ADM, Hubei Artec Biotechnology Co., Foodchem International Corporation, Fengchen Group, Ajinomoto Co., Cargill, Evonik Industries AG, Futerro, DMC Biotechnologies, Other Key Players. |

➤ Directly purchase a copy of the report – https://market.us/purchase-report/?report_id=154994

Key Market Segments

Product Type Analysis

Alcohols lead the fermentation chemicals market, capturing a 46.8% share due to their extensive applications in food, energy, and healthcare industries. The market is segmented into alcohols, organic acids, enzymes, and other chemicals.

Ethanol, a key alcohol, is integral to the food and beverage sector, serving as a primary component in beer, wine, and spirits, while also functioning as a solvent, preservative, and processing agent in various food applications. In the energy sector, ethanol and methanol are utilized as renewable fuels and fuel additives.

End-Use Industry Analysis

The food and beverage industry dominates the fermentation chemicals market, holding a 41.8% share in 2024. The market is divided into pharmaceuticals, food and beverages, agriculture, plastics & fibers, energy & fuel, and other industries.

The food and beverage sector’s prominence stems from its use of fermentation chemicals to preserve, enhance flavor, and improve the nutritional quality of perishable foods. The growing demand for natural and minimally processed products further drives this segment, as fermentation chemicals produce inhibitory compounds that prevent the growth of harmful microorganisms.

Regional Analysis

In 2024, North America led the global fermentation chemicals market, accounting for a 36.2% share and a value of approximately USD 30.5 billion. This dominance is driven by the region’s expanding healthcare and pharmaceutical industries, coupled with significant investments in research and development for advanced fermentation technologies.

Biotech firm Liberation Labs secured USD 50.5 million to construct a large-scale precision fermentation facility in Richmond, Indiana, with a 600,000-liter fermentation capacity and a dedicated downstream process.

The presence of major players in the food, pharmaceutical, and cosmetics industries further fuels market growth. Europe is another key region, driven by sustainable manufacturing practices and advancements in the energy sector, supported by the European Union’s regulations that promote bio-based chemicals and enzymes.

Top Use Cases

- Food and Beverage Production: Fermentation chemicals like enzymes and organic acids enhance food quality, flavor, and shelf life. They’re used in dairy (yogurt, cheese), beverages (beer, wine), and baked goods (bread). These chemicals ensure consistent taste and preservation, meeting the rising demand for natural, tasty, and long-lasting food products.

- Pharmaceutical Manufacturing: Fermentation chemicals, such as antibiotics, enzymes, and amino acids, are vital for producing vaccines, insulin, and other drugs. They support biopharmaceutical processes, ensuring high-quality, effective medicines. The growing need for biologics and biosimilars drives their use, especially in treating chronic diseases like diabetes and cancer.

- Biofuel Production: Fermentation chemicals, like ethanol and organic acids, are key in producing biofuels such as ethanol and biodiesel. They help convert renewable feedstocks like corn and sugarcane into eco-friendly fuels, reducing reliance on fossil fuels. This supports global sustainability goals and meets the rising demand for cleaner energy alternatives.

- Industrial Applications: Fermentation chemicals, including alcohols and enzymes, speed up chemical reactions in industries like textiles, plastics, and biochemicals. They enable efficient production of bio-based materials, reducing environmental impact. Their versatility supports innovation in sustainable manufacturing, catering to industries seeking greener, cost-effective solutions.

- Animal Feed Additives: Amino acids and enzymes from fermentation improve animal feed quality, enhancing meat production and animal health. They boost nutrient absorption and muscle growth in livestock, meeting the growing global demand for high-quality meat. This supports sustainable farming practices and efficient use of feedstocks.

Recent Developments

1. BASF SE

BASF is leveraging fermentation to expand its biopolymer portfolio, particularly with bio-based succinic acid under the brand name Juveneo. Sourced from renewable raw materials, it is a key building block for biodegradable plastics like PBS. Recent developments focus on optimizing production strains and processes to enhance yield and sustainability for large-scale industrial production.

2. Amyris, Inc.

Amyris continues to pioneer the use of synthetic biology and fermentation to produce high-value ingredients. A key recent development is the expansion of its squalane and hemisqualane production, used in cosmetics and clean beauty products.

3. DuPont Nutrition & Biosciences

Following its merger with IFF, the division continues to be a leader in microbial fermentation for food, health, and biosciences. A major recent focus is on bio-protection cultures, using fermentation-produced antimicrobials to reduce food waste and extend shelf life naturally.

4. Valero

As a leading ethanol producer, Valero’s primary fermentation chemical is renewable fuel. Recent developments are centered on carbon capture and sequestration (CCS) to drastically reduce the carbon intensity (CI) of their ethanol. A flagship project is at their Dakota Ethanol plant, where capturing and storing CO₂ emissions from fermentation is a key step toward producing net-zero transportation fuel.

5. ADM

ADM is aggressively expanding its fermentation capacity for alternative proteins and sustainable solutions. A landmark recent development is a joint venture with LG Chem to produce lactic acid and polylactic acid (PLA) bioplastics from corn sugar. This capitalizes on the demand for compostable plastics.

Conclusion

The Fermentation Chemicals Market is growing steadily due to their eco-friendly nature and wide applications in food, pharmaceuticals, biofuels, industrial processes, and animal feed. Rising consumer demand for sustainable products, advancements in biotechnology, and supportive regulations drive market expansion. Despite challenges like high production costs, innovations in fermentation technology offer significant growth opportunities, especially in emerging economies, ensuring a promising future for the industry.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)