Table of Contents

Overview

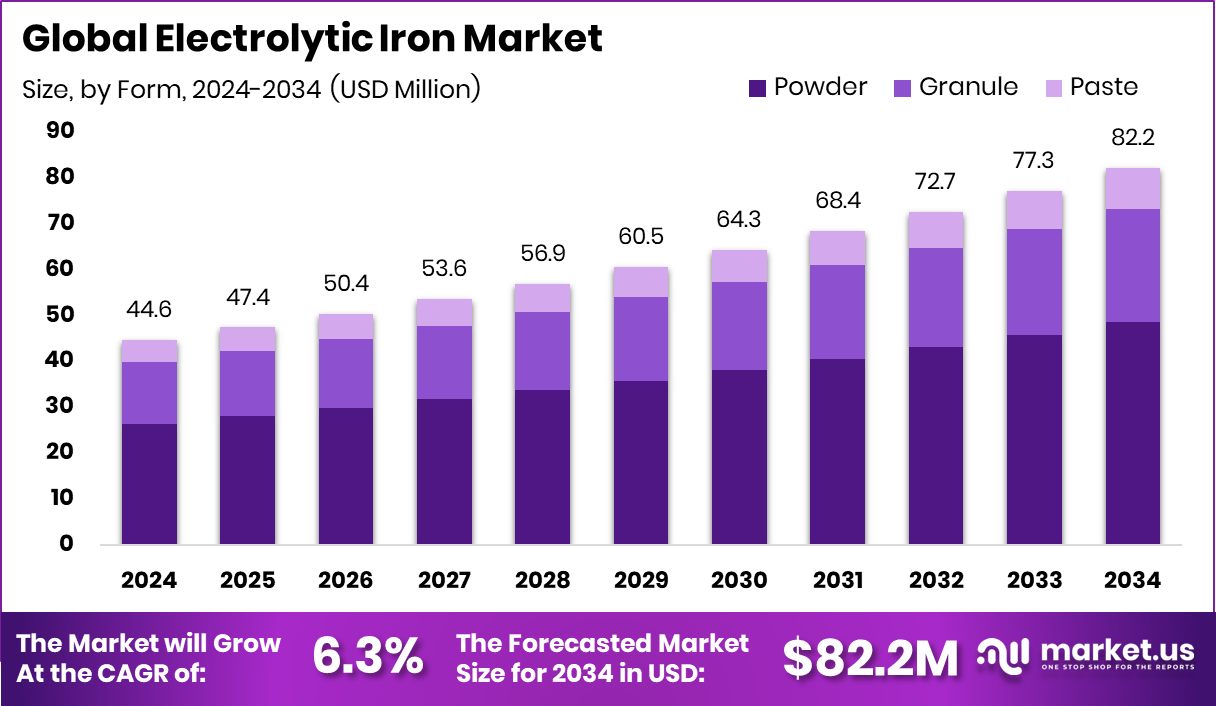

The global electrolytic iron market is set for steady expansion, with market value projected to rise from USD 44.6 million in 2024 to around USD 82.2 million by 2034, reflecting a 6.3% CAGR over the forecast period. Asia-Pacific remains the leading regional contributor, accounting for 43.70% of global demand, equivalent to USD 19.4 million, supported by strong manufacturing activity and materials innovation across the region.

Electrolytic iron is a high-purity iron produced through an electrochemical deposition process that ensures minimal impurities and uniform structure. These characteristics make it essential for applications requiring predictable performance, such as advanced manufacturing, specialty alloys, magnetic materials, and emerging energy systems. Unlike conventional iron products, electrolytic iron is selected for quality consistency rather than volume, aligning well with technology-driven industries.

Market growth is closely tied to rising investments in energy storage and magnetic technologies. Iron-air battery developer Form Energy raised $405 million, partnered with GE Vernova, expanded its West Virginia operations, and announced a 1.5 MW/150 MWh commercial pilot, reinforcing future demand for high-quality iron inputs. Research funding also plays a key role, with over $2.5 million directed toward advanced ferrimagnetic materials and a $1.3 million grant awarded to UTA to support U.S. magnet manufacturing.

On the industrial side, Niron Magnetics secured $10 million to develop a 190,000-square-foot facility, while Noveon Magnetics raised $75 million in Series B funding. Additional momentum comes from multiple $65 million funding rounds by U.S.-based magnet startups, strengthening domestic supply chains and creating long-term opportunities for electrolytic iron adoption.

Top Key Players in the Market

- Blyth Metals Ltd.

- Dr. Fritsch

- Hoganas High Alloys LLC

- Industrial Metal Powders Pvt. Ltd.

- JFE Steel Corporation

- NetShape Nutrition Pvt. Ltd.

- Shanghai Zhiye Industry Co., Ltd.

- Toho Zinc Co., Ltd.

1. Blyth Metals Ltd.

Blyth Metals Ltd. specializes in supplying high-grade metal powders and alloy materials used across industrial, engineering, and technical applications. The company focuses on reliable sourcing and tailored solutions for manufacturers requiring consistent metal performance. Their operations emphasize quality assurance and material traceability, helping them serve customers in precision manufacturing, metallurgy, and specialized product formulation.

The company maintains a strong commitment to customer-centric service, offering flexible supply formats and product customization. Their material portfolio includes electrolytic iron powders, alloy blends, and specialty forms meeting strict purity and consistency standards. EBlyth Metals operates with a focus on long-term partnerships and technical product support.

| Attribute | Details |

|---|---|

| Headquarters | United Kingdom |

| Key Offering | Metal powders & specialty alloys |

| Industry | Metals & Materials |

| Quality Focus | High-purity industrial metals |

| Market Focus | Manufacturing & metallurgy |

| Website | https://www.eblyth.com |

2. Dr. Fritsch

Dr. Fritsch is a leading manufacturer of machinery, components, and materials for diamond tool production. The company supports industries such as construction, stone processing, and precision cutting technologies. Their catalog includes presses, mixers, industrial furnaces, and specialized materials that support efficient tool manufacturing with high accuracy and controlled performance.

The company emphasizes technology leadership, automation, and engineering innovation. Their equipment is widely adopted for sintering, hot pressing, and diamond tool formulation. Dr. Fritsch’s integrated systems help customers enhance productivity, reduce waste, and achieve consistent tool quality across large-scale operations.

| Attribute | Details |

|---|---|

| Headquarters | Germany |

| Established | 1953 |

| Key Products | Diamond tool machinery & materials |

| Industry | Manufacturing Equipment |

| Technology Focus | Pressing, sintering, automation |

| Website | https://www.drfritsch.de |

3. Höganäs High Alloys LLC

Höganäs High Alloys LLC operates under Höganäs Group, a global leader in metal powder technology. The company delivers high-performance alloy powders used in automotive parts, surface coating, additive manufacturing, and industrial components. Their focus is on innovation-driven powder solutions engineered to support improved performance and sustainability.

With a strong research and development foundation, Höganäs supports advanced material applications, enabling lightweight components, better durability, and reduced lifecycle costs. Their alloy portfolio delivers consistent purity and tailored compositions suited for demanding industrial environments.

| Attribute | Details |

|---|---|

| Parent Company | Höganäs AB |

| Headquarters | Sweden (Global) |

| Industry | Metal Powder Manufacturing |

| Key Products | Alloy metal powders |

| Technical Strength | R&D-driven materials |

| Website | https://www.hoganas.com |

4. Industrial Metal Powders Pvt. Ltd. (IMP)

Industrial Metal Powders (India) Pvt. Ltd. is a global producer of high-purity electrolytic iron powder. Their products serve pharmaceuticals, food fortification, manufacturing, welding, and chemical applications. The company is known for consistent quality, high purity levels, and sustainable production practices.

IMP operates technologically advanced facilities in India and exports to more than 33 countries. Their approach focuses on innovation, product reliability, and environmentally conscious manufacturing aligned with global quality certifications.

| Attribute | Details |

|---|---|

| Headquarters | Pune, India |

| Established | 1974 |

| Key Product | Electrolytic iron powder |

| Export Reach | 33+ countries |

| Certifications | ISO-compliant systems |

| Website | https://imp-india.com |

5. JFE Steel Corporation

JFE Steel Corporation is one of Japan’s leading steel manufacturers, producing a wide range of high-grade steel products for automotive, construction, energy, and industrial applications. Their operations emphasize high-efficiency steelmaking, advanced research, and environmentally aligned processes.

JFE Steel maintains an extensive global supply chain, providing steel plates, coils, tubes, and specialty materials. Its continuous innovation supports major industrial sectors requiring reliable and high-strength steel solutions.

| Attribute | Details |

|---|---|

| Headquarters | Tokyo, Japan |

| Parent Group | JFE Holdings, Inc. |

| Industry | Steel Manufacturing |

| Key Products | Steel sheets, plates, pipes |

| Technology Focus | Eco-friendly steelmaking |

| Website | https://www.jfe-steel.co.jp |

6. NetShape Nutrition Pvt. Ltd.

NetShape Nutrition Pvt. Ltd. offers specialized nutritional and health-oriented products, focusing on customized formulations for wellness, sports nutrition, and dietary applications. Their manufacturing solutions emphasize efficiency, controlled quality, and specialized ingredient processing.

The company provides product development and contract manufacturing support for nutrition brands, combining formulation expertise with flexible production capabilities. Their offerings cater to diverse health-focused industries.

| Attribute | Details |

|---|---|

| Headquarters | India |

| Key Offering | Nutritional product manufacturing |

| Services | Contract manufacturing & formulation |

| Industry | Nutrition & wellness |

| Website | https://www.shreenutrition.com |

7. Shanghai Zhiye Industry Co., Ltd.

Shanghai Zhiye Industry Co., Ltd. supplies metal powders, alloy powders, and industrial materials used in electronics, machinery, metallurgy, and manufacturing sectors. The company focuses on high-purity metal-based solutions tailored to technical applications requiring precision.

Its product lines include electrolytic iron powders, steel powders, alloy blends, and customized formulations. Shanghai Zhiye supports industrial clients with flexible supply options and quality-assured materials.

| Attribute | Details |

|---|---|

| Headquarters | Shanghai, China |

| Key Products | Metal & alloy powders |

| Industry | Material Manufacturing |

| Market Areas | Electronics, metallurgy, machinery |

| Website | http://www.metal-powder.com |

8. Toho Zinc Co., Ltd.

Toho Zinc Co., Ltd. is a Japanese producer of zinc, zinc alloys, electronic materials, and related industrial products. The company serves industries such as automotive, electronics, construction, and energy storage through advanced refining technologies and sustainable production systems.

Toho Zinc operates across mining, smelting, recycling, and material development, ensuring a stable supply of high-quality zinc-based materials. Their integrated value chain supports long-term industrial demand.

| Attribute | Details |

|---|---|

| Headquarters | Tokyo, Japan |

| Established | 1937 |

| Key Products | Zinc, zinc alloys, electronic materials |

| Industry | Non-ferrous metals |

| Technology Focus | Refining & recycling |

| Website | https://www.toho-zinc.co.jp |

Conclusion

The electrolytic iron market continues to benefit from rising demand for high-purity materials used in advanced manufacturing, energy storage, and magnetic applications. Its purity and consistent performance make it a preferred choice in sectors where reliability matters more than volume. Growing interest in next-generation batteries, strengthened magnet production, and expanding research activity further reinforce its long-term relevance.

As industries shift toward cleaner processes, precision components, and innovation-driven technologies, electrolytic iron remains an essential input supporting this transition. With increasing investments, broader application potential, and improving production capabilities, the material stands well-positioned for steady and sustained adoption across global markets.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)