Table of Contents

Overview

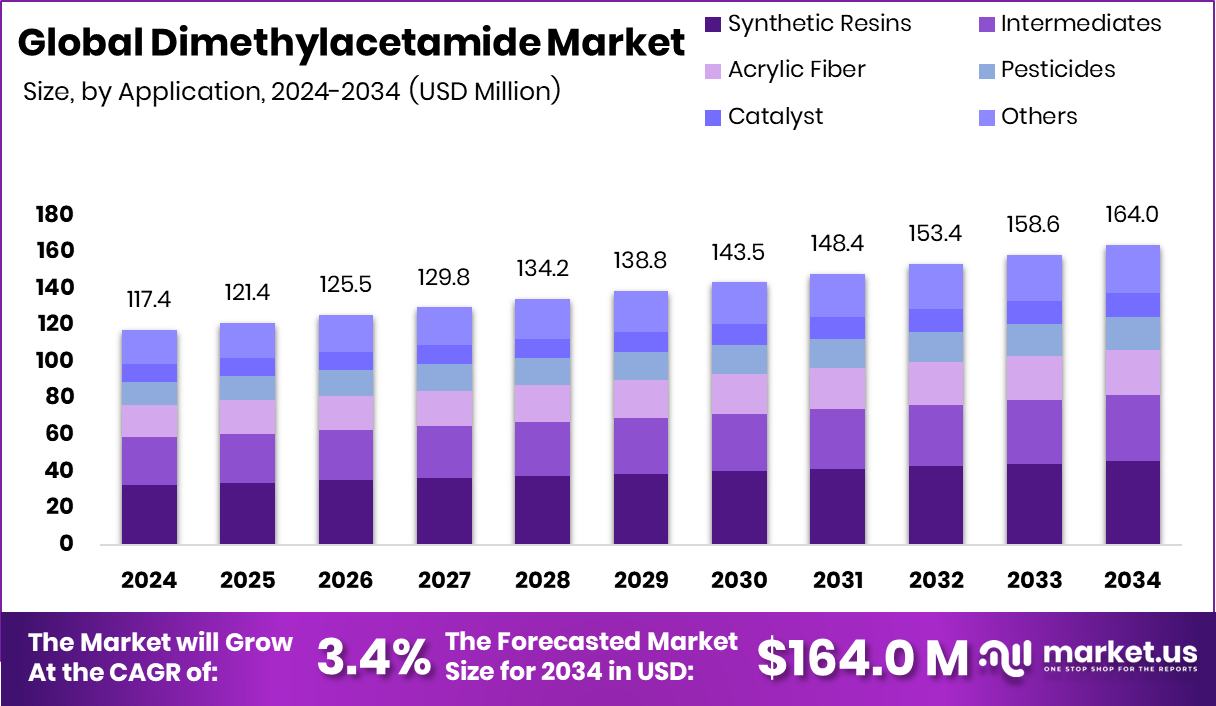

New York, NY – Nov 05, 2025 – The global Dimethylacetamide (DMAc) market is projected to reach USD 164.0 million by 2034, up from USD 117.4 million in 2024, growing at a CAGR of 3.4%. Asia-Pacific dominates with a 43.9% share, valued at USD 51.5 million, driven by rising polymer and pharmaceutical output.

DMAc’s strong solvency and thermal stability make it vital in polymer spinning, coatings, agrochemicals, and pharmaceuticals. Market growth is fueled by expanding synthetic fiber and agrochemical sectors, aided by government incentives and industrial R&D.

India’s pesticide subsidy scheme—offering Rs 4,300 products at Rs 2,150—has boosted solvent demand, while Kotak’s Rs 375 crore agrochemical investment and BiocSol’s €5.2 million microbial pesticide funding highlight strong downstream expansion. Agrim’s $17.3 million crop-input initiative and Brazil’s $2.2 billion pesticide tax relief further amplify DMAc usage in pesticide formulation.

Regulatory shifts such as the U.S. $15 million PFAS research withdrawal are promoting greener solvent innovation. With growing focus on sustainable agriculture, bio-based chemicals, and polymer efficiency, DMAc remains a critical industrial solvent supporting cleaner production and agricultural modernization globally.

➤ Click the sample report link for complete industry insights: https://market.us/report/global-dimethylacetamide-market/request-sample/

Key Takeaways

- The Global Dimethylacetamide Market is expected to be worth around USD 164.0 million by 2034, up from USD 117.4 million in 2024, and is projected to grow at a CAGR of 3.4% from 2025 to 2034.

- In 2024, the Dimethylacetamide Market saw synthetic resins application holding 27.8% due to polymer versatility.

- The pharmaceutical sector dominated the Dimethylacetamide Market with a 38.6% share, driven by solvent-grade drug formulation.

- The Asia-Pacific region achieved a market value of USD 51.5 million during 2024’s industrial expansion.

➤ Directly purchase a copy of the report – https://market.us/purchase-report/?report_id=163207

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2024) | USD 117.4 Million |

| Forecast Revenue (2034) | USD 164.0 Million |

| CAGR (2025-2034) | 3.4% |

| Segments Covered | By Application (Synthetic Resins, Intermediates, Acrylic Fiber, Pesticides, Catalyst, Others), By End- Use (Pharmaceutical, Agrochemical, Personal Care, Textile, Others) |

| Competitive Landscape | AK-Kim Kimya, BASF SE, Dupont, Eastman Chemical Company, Holy Stone Enterprise Co., Ltd, Mitsubishi Gas Chemical Company, Samsung Fine Chemicals Co., Ltd, Others |

Key Market Segments

By Application Analysis

In 2024, Synthetic Resins dominated the By Application segment of the Dimethylacetamide Market, capturing a 27.8% share. This leadership stems from Dimethylacetamide’s essential role as a solvent in resin synthesis, where its excellent solubility and thermal stability enable consistent polymerization and superior film formation.

It is widely used in producing high-performance coatings, adhesives, and polymer systems, ensuring durability and precision across applications. The segment benefits from rising demand for advanced synthetic resins in industries such as automotive, construction, and industrial coatings.

Ongoing innovations in resin formulations and the expanding use of specialty materials further strengthen this segment’s position, sustaining its substantial market contribution and driving continuous growth across major manufacturing regions globally.

By End-Use Analysis

In 2024, the Pharmaceutical segment led the By End-Use category of the Dimethylacetamide Market, accounting for a 38.6% share. This leadership reflects Dimethylacetamide’s crucial role as a reaction and crystallization solvent in producing active pharmaceutical ingredients (APIs). Its high solvency power, purity, and stability enable efficient drug formulation and controlled synthesis, supporting consistent product quality.

The rising demand for advanced, high-purity solvents in modern drug manufacturing and research further strengthens its market standing. Additionally, strict regulatory focus on solvent quality, production efficiency, and safety reinforces Dimethylacetamide’s indispensable position in pharmaceutical applications, ensuring the segment’s continued dominance and contribution to global market growth.

Regional Analysis

In 2024, Asia-Pacific dominated the Dimethylacetamide Market with a 43.9% share, valued at USD 51.5 million. This dominance is driven by strong industrial growth in pharmaceuticals, polymers, and coatings, supported by expanding manufacturing in China, India, and Japan.

Government incentives promoting sustainable materials and increasing chemical production capacity have further strengthened DMAc demand in the region. North America ranked next, supported by advancements in high-purity solvents for pharmaceuticals and resin production, while Europe maintained stable growth through stringent quality standards and specialty chemical focus.

The Middle East & Africa witnessed moderate expansion with rising investments in coatings, and Latin America, led by Brazil and Mexico, experienced gradual growth due to increasing agrochemical manufacturing. Overall, Asia-Pacific remains the leading region, reflecting its robust industrial base, innovation-driven manufacturing, and expanding chemical infrastructure.

Top Use Cases

- Membrane and film production: DMAc is used to produce polymer-based membranes (e.g., for dialysers) and films owing to its capability to dissolve polymers used for membranes, and its high stability in processing.

- Electronics/manufacturing cleaning and stripping: In electronics manufacturing, DMAc is used as a solvent for photoresist strippers and other cleaning processes because of its strong solvency and ability to remove hardened polymers from surfaces.

- Pharmaceutical manufacturing solvent: DMAc serves as a reaction and crystallization medium in active pharmaceutical ingredient (API) production. Its strong solvency, purity, and miscibility with water support efficient drug-making processes.

- Synthetic resin and coatings production: Because DMAc dissolves many resins (like polyurethane, polyimide) and has a high boiling point, it is used in formulating coatings and adhesives—helping deliver uniform film formation and curing.

- Fiber & polymer spinning: DMAc is widely used as a solvent in spinning synthetic fibers such as polyacrylonitrile and polyurethane. Its ability to dissolve high-molecular-weight polymers and maintain stability during wet or dry spinning makes it ideal for producing uniform fibers.

Recent Developments

- In December 2024, Akkim published its Sustainability Report. The company reiterated its commitment to chemical industry development and sustainability, but this document did not reference any launch or acquisition specifically for DMAc.

- In June 2024, DuPont announced an agreement to acquire Donatelle Plastics Incorporated, a medical-device contract manufacturer.

Conclusion

The Dimethylacetamide market continues to grow steadily, driven by its essential role across diverse industrial applications. Its strong solvency, stability, and compatibility with various chemicals make it vital in pharmaceuticals, polymers, coatings, and agrochemical formulations. Expanding use in high-performance materials and sustainable production processes enhances its industrial importance.

Growing emphasis on cleaner solvent systems and green chemistry practices further strengthens future opportunities. Continuous technological advancements, regulatory support, and innovation in specialty solvents are expected to sustain market momentum. With its versatility and reliability, Dimethylacetamide remains a key component supporting advancements in modern manufacturing and chemical synthesis worldwide.