Table of Contents

Overview

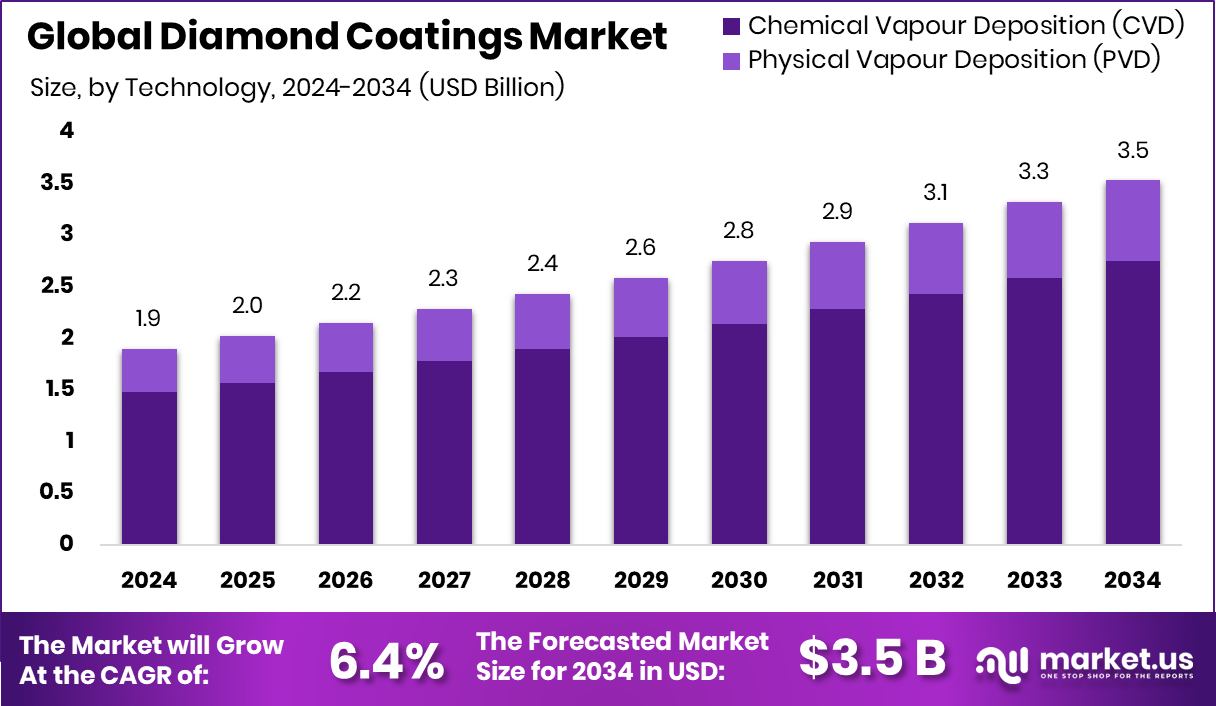

New York, NY – August 08, 2025 – The Global Diamond Coatings Market is projected to grow from USD 1.9 billion in 2024 to USD 3.5 billion by 2034, achieving a CAGR of 6.4% from 2025 to 2034. North America’s USD 0.8 billion market is propelled by strong demand in electronics and aerospace.

Diamond coatings are thin diamond films applied to surfaces like metals, ceramics, or glass to enhance durability. Produced primarily via chemical vapor deposition (CVD), these coatings offer exceptional hardness, thermal conductivity, wear resistance, and chemical stability. They are widely used in cutting tools, optical lenses, electronics, and biomedical implants for superior performance.

The diamond coatings market includes the global production, distribution, and application of synthetic diamond films across industries like electronics, automotive, and aerospace. It involves manufacturers, equipment suppliers, end-users, and innovators improving coating technologies.

Key drivers include the need for durable, high-performance coatings that extend equipment life and reduce wear. Electronics and aerospace sectors leverage diamond coatings for heat dissipation and structural strength, while precision manufacturing in the medical and automotive industries boosts adoption. Rising demand for high-speed machining, miniaturized electronics, and corrosion-resistant surfaces further fuels growth. Additionally, the expansion of renewable energy, particularly solar panels, increases the use of diamond-coated components.

Key Takeaways

- The Global Diamond Coatings Market is expected to be worth around USD 3.5 billion by 2034, up from USD 1.9 billion in 2024, and is projected to grow at a CAGR of 6.4% from 2025 to 2034.

- In the Diamond Coatings Market, Chemical Vapour Deposition (CVD) dominates with a 77.8% technology share.

Metal substrates lead the Diamond Coatings Market by substrate, accounting for 48.2% of total usage. - The Electrical and Electronics end-use sector holds the largest share in the Diamond Coatings Market at 38.6%.

- The North American market reached a value of USD 0.8 billion in 2024.

➤ Curious about the content? Explore a sample copy of this report – https://market.us/report/global-diamond-coatings-market/request-sample/

Report Scope

| Market Value (2024) | USD 1.9 Billion |

| Forecast Revenue (2034) | USD 3.5 Billion |

| CAGR (2025-2034) | 6.4% |

| Segments Covered | By Technology (Chemical Vapour Deposition (CVD), Physical Vapour Deposition (PVD)), By Substrate (Metal, Ceramic, Composite, Others), By End Use (Electrical and Electronics, Medical, Industrial, Automotive, Others) |

| Competitive Landscape | Anglo American plc, Blue Wave Semiconductors Inc., Calico Coatings, CemeCon AG, Creating Nano Technologies Inc., Crystallume Corp., Diamond Materials GmbH and Co. KG, Element Six UK Ltd., Endura Coatings LLC, IBC Coatings Technologies Inc., JCS Technologies Pte Ltd, NeoCoat SA, OC Oerlikon Corp. AG, RobbJack Corporation, Sandvik AB |

➤ Directly purchase a copy of the report – https://market.us/purchase-report/?report_id=153887

Key Market Segments

By Technology Analysis

Chemical Vapor Deposition (CVD) leads the diamond coatings market, holding a 77.8% share in 2024.

CVD dominates the By Technology segment due to its ability to produce high-purity, uniform diamond films with strong adhesion across diverse substrates. Its precision in coating complex shapes makes it ideal for industries like electronics, optics, and cutting tools, where it enhances hardness, thermal conductivity, and wear resistance without compromising substrate integrity.

Advancements in CVD technology have improved efficiency and reduced costs, reinforcing its widespread use in research and industrial applications. As demand grows for high-performance coatings in advanced manufacturing and thermal management, CVD’s reliability and scalability ensure its continued dominance in the global market.

By Substrate Analysis

Metal substrates dominate the diamond coatings market, with a 48.2% share in 2024.

Metal substrates lead the By Substrate segment due to their compatibility with diamond coatings, which enhance wear resistance, thermal stability, and surface hardness. Commonly coated metals like steel, titanium, and tungsten are used in cutting tools, medical instruments, and mechanical components under extreme conditions.

The strong adhesion of diamond films on metals supports durability in high-speed machining and precision manufacturing, while their thermal conductivity suits heat-intensive applications in aerospace, automotive, and heavy engineering. The widespread use of metal components and the focus on reducing maintenance costs solidify this segment’s leading position.

By End Use Analysis

The Electrical and Electronics sector leads the diamond coatings market, with a 38.6% share in 2024.

The Electrical and Electronics segment dominates the By End Use category, driven by the need for materials with superior thermal conductivity, electrical insulation, and durability in electronic devices. Diamond coatings are applied to semiconductors, heat sinks, circuit boards, and optical windows to boost efficiency and longevity.

As device miniaturization increases the demand for effective heat management, diamond coatings are critical for compact, high-performance electronics. Their durability enhances reliability in sensitive assemblies, while global growth in electronics production, especially in innovative and automated regions, cements this segment’s leading role.

Regional Analysis

North America leads the diamond coatings market, capturing a 45.7% share in 2024, valued at USD 0.8 billion.

North America dominates the global market, driven by its strong aerospace, electronics, and automotive sectors, which demand advanced coatings for durability and precision. Europe follows, supported by its advanced industrial base and growing use of diamond coatings in precision engineering and medical tools.

Asia Pacific shows steady growth, fueled by semiconductor manufacturing and industrial tooling investments in countries like China, Japan, and South Korea. The Middle East & Africa and Latin America are emerging markets, with increasing applications in oilfield drilling and industrial wear protection. North America’s technological advancements and high-value applications maintain its position as the market’s core hub.

Top Use Cases

- Electronics – Heat Management: Diamond coatings are used on semiconductors and heat sinks to manage heat in compact devices. Their high thermal conductivity ensures efficient cooling, improving device performance and lifespan. This is critical for smartphones, laptops, and high-frequency communication systems, where overheating can reduce efficiency and reliability.

- Aerospace – Component Durability: In aerospace, diamond coatings enhance the durability of turbine blades and cutting tools. Their extreme hardness and wear resistance protect parts under high-stress conditions, extending service life. This reduces maintenance costs and improves safety in aircraft engines and structural components.

- Automotive – Engine Efficiency: Diamond coatings reduce friction in engine parts like pistons and gears. This improves fuel efficiency, lowers emissions, and extends component life. Used in high-performance vehicles, these coatings support smoother operation and reduced wear, contributing to cost savings and eco-friendly automotive solutions.

- Medical – Biocompatible Implants: Diamond coatings are applied to medical implants and surgical tools for their biocompatibility and durability. They reduce rejection risks and enhance integration with body tissues. Used in dental implants and joint replacements, these coatings ensure long-lasting performance and patient safety.

- Renewable Energy – Solar Panel Efficiency: In solar panels, diamond coatings improve durability and efficiency. Their wear resistance protects components from environmental damage, while high thermal conductivity aids heat dissipation. This extends panel lifespan and enhances energy output, supporting the growth of sustainable energy solutions.

Recent Developments

1. Anglo American plc

Anglo American, through its subsidiary Element Six, is advancing diamond coatings for industrial and technological applications. Recently, they developed ultra-hard chemical vapor deposition (CVD) diamond coatings for cutting tools, enhancing durability in aerospace and automotive machining. They also partnered with quantum computing firms to produce high-purity diamond coatings for quantum sensors. Their innovations focus on sustainability, reducing wear and energy consumption in heavy industries.

2. Blue Wave Semiconductors Inc.

Blue Wave Semiconductors specializes in diamond-like carbon (DLC) coatings for semiconductors. Their latest breakthrough involves low-temperature diamond coatings for flexible electronics, enabling next-gen wearable devices. They also introduced a plasma-enhanced CVD process to improve adhesion on silicon substrates, benefiting microelectronics and optoelectronics. Their coatings enhance thermal management in high-power LED and RF devices.

3. Calico Coatings

Calico Coatings has expanded its nanocrystalline diamond (NCD) coatings for medical implants, improving biocompatibility and wear resistance. Their recent innovation includes antibacterial diamond coatings for surgical tools, reducing infection risks. They also developed tribological diamond coatings for automotive components, extending engine part lifespan. Their focus is on eco-friendly deposition techniques to minimize chemical waste.

4. CemeCon AG

CemeCon AG launched CCDia Boost, a new diamond coating for cutting tools, offering longer tool life in high-speed machining of composites and non-ferrous metals. They also introduced a multi-layer diamond coating technology combining CVD and PVD for extreme conditions. Their coatings are widely adopted in the aerospace and mold-making industries.

5. Creating Nano Technologies Inc.

Creating Nano Technologies has innovated hybrid diamond-graphene coatings for energy storage, improving battery electrode performance. Their nano-diamond coatings are also used in MEMS and NEMS devices for enhanced durability. Recently, they partnered with a solar panel manufacturer to apply anti-reflective diamond coatings, boosting photovoltaic efficiency.

Conclusion

Diamond coatings are transforming industries with their unmatched hardness, thermal conductivity, and durability. From enhancing electronics and aerospace components to improving medical implants and renewable energy systems, their versatile applications drive efficiency and innovation. As demand for high-performance, sustainable solutions grows, the diamond coatings market is poised for significant expansion, offering substantial opportunities for manufacturers and end-users alike.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)