Table of Contents

Overview

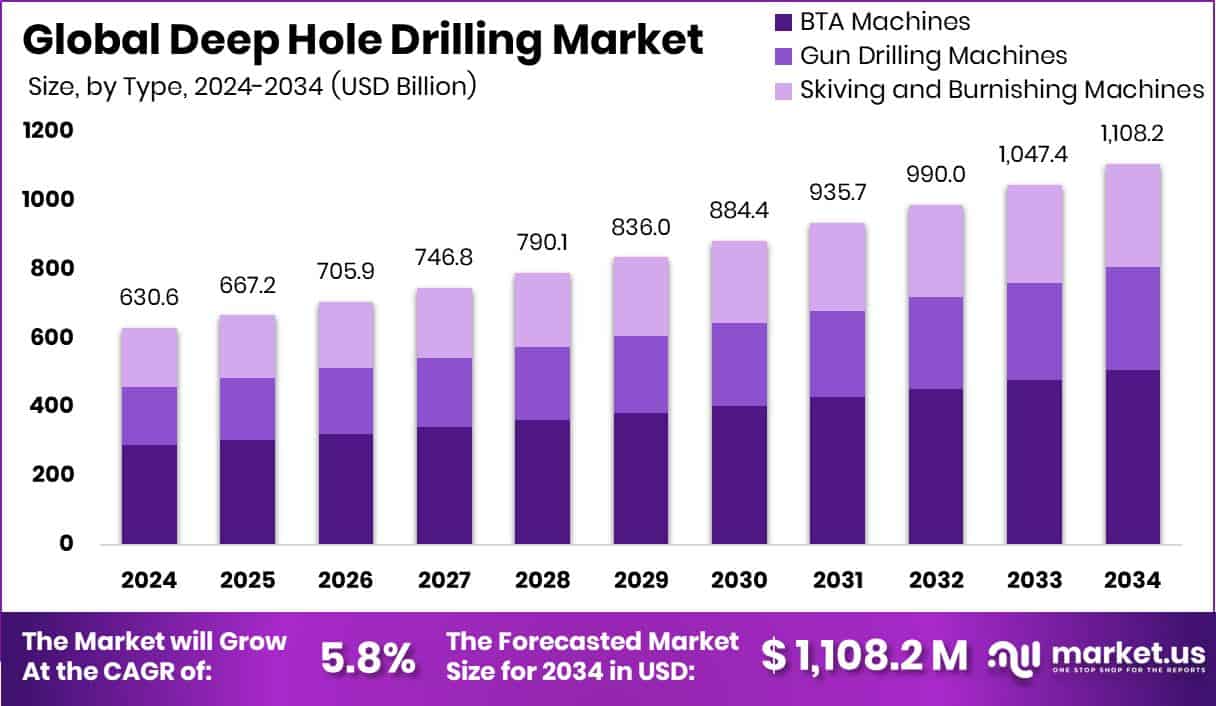

New York, NY – August 11, 2025 –The Global Deep Hole Drilling Market is forecast to climb from USD 630.6 million in 2024 to USD 1,108.2 million by 2034, expanding at a CAGR of 5.8% between 2025 and 2034. Asia-Pacific retained dominance in 2024 with a 42.80% share, driven by robust manufacturing activity. Deep hole drilling, defined as producing holes exceeding ten times their diameter, is vital for precision parts such as crankshafts, hydraulic cylinders, molds, and fuel injectors.

It plays a critical role in aerospace, automotive, oil & gas, medical, and energy sectors where standard drilling falls short. Growth is propelled by rising demand for high-accuracy components in defense, heavy machinery, and energy infrastructure, alongside increasing adoption of automated, high-speed drilling solutions to minimize downtime. Complex parts in aerospace, automotive, and oilfield applications—like engine blocks, transmission systems, and fuel systems—further drive demand, while miniaturization trends require advanced machining for intricate internal features.

Industry developments include Borobotics raising CHF 1.3 million for geothermal drilling automation, Western Mines receiving a $440 government grant to expand its Oldfields drilling program, and Quaise securing $40 million to advance ultra-deep geothermal drilling technology.

Key Takeaways

- The Global Deep Hole Drilling Market is expected to be worth around USD 1,108.2 million by 2034, up from USD 630.6 million in 2024, and is projected to grow at a CAGR of 5.8% from 2025 to 2034.

- In the Deep Hole Drilling Market, BTA machines account for a dominant 45.8% type-wise share.

- CNC operations lead the market with a 78.4% share, enabling precision and automation in deep drilling.

- The automotive sector dominates end-user demand, contributing a significant 45.2% share in 2024.

- OEM distribution channels hold a major 71.2% market share, reflecting direct demand from equipment manufacturers.

- The Asia-Pacific market reached a total value of USD 269.8 million in 2024.

➤ Curious about the content? Explore a sample copy of this report – https://market.us/report/global-deep-hole-drilling-market/request-sample/

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2024) | USD 630.6 Million |

| Forecast Revenue (2034) | USD 1,108.2 Million |

| CAGR (2025-2034) | 5.8% |

| Segments Covered | By Type (BTA Machines, Gun Drilling Machines, Skiving and Burnishing Machines), By Operation (CNC, Non-CNC), By End-user (Automotive, Oil and Gas, Medical, Construction and Mining, Energy, Aerospace, Military and Defense, Others), By Distribution Channel (Original Equipment Manufacturer (OEM), Aftermarket) |

| Competitive Landscape | Entrust Manufacturing Technologies, Inc, HONG JI Precision Machinery Ltd., Dsgundrill, Mollart Engineering Limited, TBT Tiefbohrtechnik GmbH + Co., TIBO Tiefbohrtechnik GmbH, Cheto Corporation S.A., Galbiati Costruzioni Meccaniche S.r.l., Loch Präzisions Bohrtechnik GmbH |

➤ Directly purchase a copy of the report— https://market.us/purchase-report/?report_id=154627

Key Market Segments

By Type Analysis

In 2024, BTA Machines led the By Type segment of the Deep Hole Drilling Market with a 45.8% share, driven by their efficiency in creating deep bores with larger diameters for heavy-duty applications. Known for excellent chip evacuation, stability, and minimal deviation at greater depths, BTA machines deliver consistent accuracy in large-scale manufacturing.

Their strong presence is fueled by demand from the oil & gas, heavy machinery, and energy equipment sectors, where precision drilling is vital. Offering high productivity, superior surface finish, and reduced secondary processing, they integrate well with CNC systems and accommodate large workpieces.

This combination of versatility, efficiency, and reliability has sustained their market leadership and encouraged adoption in expanding production facilities worldwide.

By Operation Analysis

In 2024, CNC dominated the By Operation segment of the Deep Hole Drilling Market with a 78.4% share, reflecting the rising reliance on computer numerical control for precision drilling. CNC deep hole drilling machines deliver superior accuracy, repeatability, and consistency, which are crucial for achieving tight tolerances and complex geometries.

Their leadership stems from growing automation needs and demand for higher throughput, as they minimize manual intervention, cut cycle times, and boost efficiency. With capabilities like multi-axis control, real-time monitoring, and seamless integration into digital manufacturing, CNC systems offer flexibility across diverse materials and part sizes, making them the standard in high-precision, high-volume production.

By End-user Analysis

In 2024, the Automotive sector led the End-User segment of the Deep Hole Drilling Market with a 45.2% share, driven by the need for precise components such as crankshafts, fuel injection systems, and transmission parts. High-volume automotive production demands deep hole drilling solutions that ensure speed, accuracy, and repeatability, with growing adoption of automation to reduce waste and downtime.

As vehicle designs move toward compact, performance-oriented platforms with intricate internal geometries, reliance on advanced deep drilling technologies has strengthened, cementing the sector’s position as a key driver of market growth.

By Distribution Channel Analysis

In 2024, Original Equipment Manufacturer (OEM) channels dominated the By Distribution Channel segment of the Deep Hole Drilling Market with a 71.2% share, driven by the direct integration of customized drilling systems into production lines. This approach ensures equipment meets specific operational needs, offering consistent performance, durability, and strong after-sales support.

OEM procurement enables tailored configurations, upgrades, and seamless integration with automation and digital controls, enhancing quality and efficiency. The 71.2% share highlights the industry’s preference for reliability, customization, and technological compatibility in high-precision manufacturing.

Regional Analysis

In 2024, Asia-Pacific led the Deep Hole Drilling Market with a 42.80% share, valued at USD 269.8 million, driven by strong manufacturing bases and rapid industrial growth in China, India, South Korea, and Japan. Expanding automotive, aerospace, and heavy machinery production has fueled demand for precision machining, while cost-effective labor, supportive policies, and infrastructure upgrades boost advanced drilling adoption.

North America and Europe show steady uptake supported by mature industries, while the Middle East & Africa grows in energy applications and Latin America sees gradual progress through industrial modernization. Asia-Pacific remains the clear leader in revenue and technology adoption.

Top Use Cases

Aircraft Components (Landing Gear & Actuators): Deep hole drilling is critical for aerospace parts like landing gear struts, actuator cylinders, and piston rods, which require extremely straight, long bores in high-strength alloys. This ensures precise fitment, strength under heavy loads, and smooth hydraulic operation. Aerospace standards demand micron-level accuracy, making advanced deep hole drilling systems indispensable.

Heat Exchanger Tube Sheets: Power plants and petrochemical facilities use tube sheets with hundreds or thousands of holes to hold heat exchanger tubes. Deep hole drilling machines create these parallel holes with perfect alignment, ensuring efficient heat transfer and leak prevention. CNC-controlled BTA drilling handles the job quickly, maintaining both hole accuracy and productivity.

Fuel Injector Bodies: Automotive and industrial engines rely on fuel injectors with very small, highly precise holes for accurate fuel spray patterns. Deep hole drilling—often via multi-spindle gundrilling—produces these holes with perfect roundness and surface finish, ensuring optimal combustion efficiency and lower emissions. Even minor deviations can impact engine performance significantly.

Hydraulic Cylinder Bores: Hydraulic cylinders in construction, mining, and industrial machinery need smooth, straight bores for proper sealing and piston movement. Deep hole drilling is followed by skiving and burnishing to achieve mirror-like finishes, reducing wear, improving efficiency, and extending service life. The process supports large diameters and long cylinder lengths.

Automotive Engine & Transmission Parts: Engine blocks, crankshafts, and transmission shafts often require long, precise oil and cooling channels. Deep hole drilling enables lighter, more compact parts by allowing thinner walls without sacrificing strength. This boosts fuel efficiency and supports modern vehicle design goals. Automation ensures these components meet strict quality and production volume targets.

Oilfield Exploration Equipment: Drill collars, downhole motors, and other oilfield components must withstand extreme pressure while maintaining structural integrity. Deep hole drilling allows precise bore placement and wall thickness control, critical for safety and performance. Specialized BTA and trepanning methods handle very large diameters and lengths used in offshore and onshore drilling rigs.

Recent Developments

- In April 2024, Century Tool, a division of Tooling Tech Group, acquired the Cheto IXN 3000—a 7-axis CNC system that integrates deep hole drilling with milling. Capable of 6,000 rpm, handling loads up to 60,000 pounds, and drilling to depths of 98 inches, it enables extended unattended operation with tool wear monitoring, enhancing mold-making productivity.

- In March 2024, TBT introduced upgraded single-lip and double-lip drills with optimized cutting-edge geometry to deliver improved bore quality and greater process stability. Designed for demanding deep-hole work, these tools achieve feed rates up to five times faster than standard carbide drills while ensuring concentricity and fine surface finishes.

Conclusion

The Deep Hole Drilling Market continues to evolve with advancements in precision, automation, and tooling technology, enabling industries to meet increasingly complex manufacturing demands. From aerospace and automotive to oilfield and energy equipment, the process delivers unmatched accuracy for critical components.

Innovations in CNC systems, multi-axis machines, and high-performance drill designs are enhancing speed, consistency, and surface quality. As sectors push for lighter, stronger, and more intricate parts, deep hole drilling remains an essential capability driving efficiency and quality in modern production.