Table of Contents

Overview

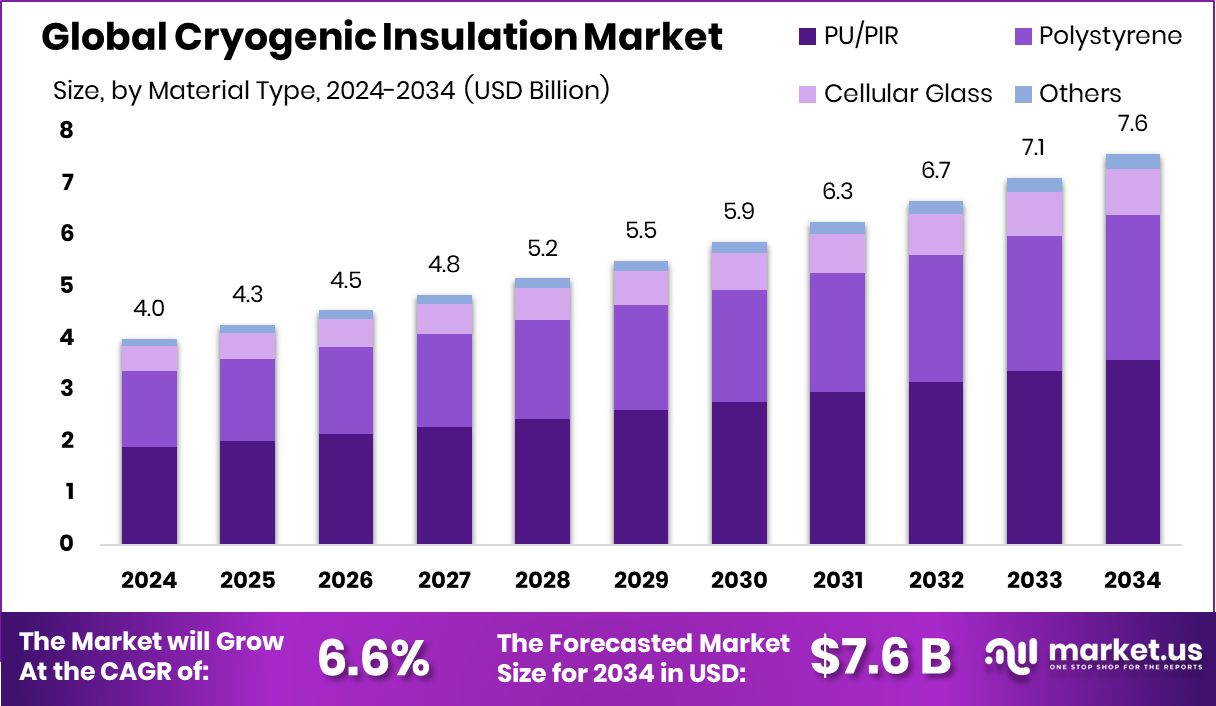

New York, NY – August 08, 2025 – The Global Cryogenic Insulation Market is projected to reach approximately USD 7.6 billion by 2034, rising from USD 4.0 billion in 2024, and is expected to expand at a compound annual growth rate (CAGR) of 6.6% from 2025 to 2034. This growth is being strongly driven by the rapid development of LNG infrastructure and hydrogen energy projects, particularly in the Asia-Pacific region, which accounted for around USD 1.8 billion in market value in 2024.

Cryogenic insulation involves the use of advanced materials designed to maintain ultra-low temperatures, typically below -150°C, for the safe storage and transport of liquefied gases such as LNG, liquid nitrogen, liquid oxygen, and hydrogen. These materials prevent heat ingress, thereby reducing evaporation losses and ensuring the stability, efficiency, and safety of cryogenic systems. Widely used materials include polyurethane foam, perlite, and multilayer insulation (MLI), which are chosen for their durability and low thermal conductivity under cryogenic conditions.

The market spans applications across various sectors, including energy, healthcare, food processing, electronics, and aerospace. The rising global adoption of LNG, along with increased use of cryogenic gases in industrial and medical applications, has significantly boosted the need for reliable insulation solutions. For instance, hospitals depend on liquid oxygen, while the semiconductor industry uses specialized cryogens, and metal processing facilities utilize gases like argon, all requiring insulated storage systems to maintain consistent low temperatures.

Government policies promoting the use of natural gas and clean hydrogen have further accelerated infrastructure investment in cryogenic transport and storage. The construction of LNG terminals, floating storage units, and regasification facilities continues to push demand for high-performance insulation systems. Additionally, sustainability initiatives are influencing material choices, with companies such as Polystyvert securing USD 16 million for polystyrene recycling technologies and an additional USD 3.5 million in public funding directed at cryogenic insulation innovation.

Similarly, TemperPack raised USD 22.5 million to develop eco-friendly insulation alternatives to Styrofoam, aiming to meet thermal needs while supporting environmental goals. Reinforcing this trend, industry-backed programs like the Foam Recycling Coalition have granted over USD 1 million. The development of advanced recycled-content insulation reflects a growing emphasis on sustainable cryogenic solutions across industries.

Key Takeaways

- The Global Cryogenic Insulation Market is expected to be worth around USD 7.6 billion by 2034, up from USD 4.0 billion in 2024, and is projected to grow at a CAGR of 6.6% from 2025 to 2034.

- PU/PIR dominates the Cryogenic Insulation Market with 47.3% due to excellent thermal performance and durability.

- Tanks lead the Cryogenic Equipment segment with 32.7%, driven by increased LNG and hydrogen storage needs.

- The energy and power sector holds a 38.3% share, reflecting rising demand for insulated liquefied gas infrastructure.

- The Asia-Pacific market reached a value of USD 1.8 billion, showing strong demand.

➤ Curious about the content? Explore a sample copy of this report – https://market.us/report/cryogenic-insulation-market/request-sample/

Report Scope

| Market Value (2024) | USD 4.0 Billion |

| Forecast Revenue (2034) | USD 7.6 Billion |

| CAGR (2025-2034) | 6.6% |

| Segments Covered | By Material Type (PU/PIR, Polystyrene, Cellular Glass, Others), By Cryogenic Equipment (Tanks, Flasks, Small Vacuum, Dewar, Pumps, Valves, Others), By End-Use (Energy and Power, Food and Beverages, Chemical, Medical, Others) |

| Competitive Landscape | Aspen Aerogels, KAEFER, BASF SE, Armacell Enterprise GmbH & Co. KG, Lydall Inc, Cabot Corporation, DUNMORE, Owens Corning, Röchling |

➤ Directly purchase a copy of the report – https://market.us/purchase-report/?report_id=153927

Key Market Segments

By Material Type

In 2024, polyurethane (PU) and polyisocyanurate (PIR) foams dominated the cryogenic insulation market, holding a 47.3% share in the material type segment. Their leadership stems from exceptional thermal insulation, low thermal conductivity, and structural stability at cryogenic temperatures (below -150°C). Widely used in LNG storage tanks, pipelines, and transport vessels, PU/PIR foams minimize boil-off losses and ensure safety.

Their closed-cell structure offers superior moisture resistance, preventing thermal degradation. The rising demand for liquefied gases in energy, medical, and industrial sectors, coupled with global LNG infrastructure growth, has solidified PU/PIR’s dominance. Their cost-effectiveness and adaptability for both prefabricated and on-site applications make them the preferred choice for large-scale cryogenic projects.

By Cryogenic Equipment

In 2024, cryogenic tanks led the equipment segment with a 32.7% share, driven by their critical role in storing and transporting liquefied gases like LNG, liquid oxygen, nitrogen, and argon. Used in LNG terminals, industrial gas facilities, and healthcare systems, tanks are vital for maintaining ultra-low temperatures, minimizing thermal losses, and ensuring safety.

The global surge in LNG consumption and gas-based infrastructure expansion has boosted tank deployments. Enhanced by multilayer insulation or materials like PU/PIR, tanks meet stringent efficiency and safety standards. Their versatility and capacity for large-volume storage reinforce their position as the leading equipment type in the market.

By End-Use

The energy and power sector dominated the end-use segment in 2024, accounting for 38.3% of the cryogenic insulation market. This is driven by the increasing reliance on LNG infrastructure, gas-fired power generation, and emerging hydrogen projects.

Cryogenic insulation ensures operational efficiency in LNG regasification plants, gas turbines, and hydrogen storage systems by minimizing thermal losses and enhancing safety. The expansion of LNG terminals, floating storage units, and hydrogen distribution networks, alongside global energy security and low-emission goals, fuels demand.

Regional Analysis

In 2024, Asia-Pacific dominated the cryogenic insulation market, capturing a 47.3% share and generating USD 1.8 billion in revenue. This leadership is fueled by significant investments in LNG infrastructure and the growing hydrogen economy.

While specific data for North America, Europe, the Middle East & Africa, and Latin America is unavailable, these regions contribute to the remaining market share, driven by industrial gas applications, healthcare, and energy infrastructure growth.

Asia-Pacific’s large-scale cryogenic deployments outpace other regions, with North America and Europe likely holding significant portions of the residual market due to established gas supply chains and clean energy initiatives.

Top Use Cases

- LNG Storage and Transportation: Cryogenic insulation is vital for storing and transporting liquefied natural gas (LNG). It maintains extremely low temperatures, preventing gas evaporation and ensuring safety. Used in tanks, pipes, and ships, it supports the growing demand for clean energy by enabling efficient LNG handling across industries like power generation and automotive.

- Aerospace and Space Exploration: In aerospace, cryogenic insulation protects rocket fuel storage systems, maintaining ultra-low temperatures for propellants like liquid hydrogen. It ensures safety and efficiency during space missions. With rising investments in space exploration, this insulation is crucial for reliable fuel storage and handling in extreme conditions.

- Medical and Healthcare Applications: Cryogenic insulation is used in medical facilities to store biological samples, vaccines, and liquid nitrogen at very low temperatures. It prevents heat ingress, ensuring sample integrity. As healthcare advances, the demand for reliable cryogenic storage systems grows, supporting research and vaccine preservation needs globally.

- Food and Beverage Industry: Cryogenic insulation aids in food processing by maintaining low temperatures for freezing and preserving perishable items. Liquid nitrogen and carbon dioxide, used in chilling, require insulated systems to minimize energy loss. This ensures food quality and safety, meeting the rising global demand for processed foods.

- Electronics and Superconducting Devices: Cryogenic insulation is essential for superconducting materials and cooling systems in electronics. It maintains low temperatures for high-performance devices like MRI machines and quantum computers. As technology advances, the need for efficient insulation in these applications grows, driving innovation and market expansion.

Recent Developments

1. Aspen Aerogels

Aspen Aerogels has been advancing its PyroThin cryogenic insulation for electric vehicle (EV) batteries and LNG applications. Their aerogel-based solutions offer superior thermal performance in extreme cold conditions. Recently, they expanded production capacity to meet growing demand in energy storage and industrial cryogenics. Aspen is also collaborating with major automakers to integrate cryogenic insulation in next-gen EVs.

2. KAEFER

KAEFER has enhanced its cryogenic insulation systems for LNG terminals and aerospace applications. Their latest innovations include modular insulation solutions for large-scale cryogenic storage, improving energy efficiency and safety. KAEFER also introduced fire-resistant cryogenic insulation materials, catering to stringent industry regulations. Their projects include partnerships with global energy firms for LNG infrastructure.

3. BASF SE

BASF has developed Slentite, a high-performance insulation material for cryogenic environments. Their research focuses on nanoporous materials that minimize heat transfer in ultra-low temperatures. BASF is also working on sustainable cryogenic insulation solutions, reducing carbon footprints in industrial applications. Recent collaborations include aerospace and hydrogen storage projects.

4. Armacell Enterprise GmbH & Co. KG

Armacell has launched ArmaFlex Cryogenic, a flexible elastomeric foam for LNG and industrial gas applications. This material provides excellent thermal insulation at cryogenic temperatures while resisting moisture and mechanical stress. Armacell is expanding its cryogenic product line to support hydrogen energy infrastructure.

5. Lydall Inc.

Lydall (now part of Unifrax) has introduced advanced cryogenic insulation mats for the aerospace and energy sectors. Their proprietary silica-based materials offer lightweight, high-performance thermal protection for liquid hydrogen and oxygen systems. Recent developments include partnerships with space exploration companies for cryogenic tank insulation.

Conclusion

Cryogenic insulation is crucial across energy, healthcare, electronics, aerospace, and food processing, driven by the rising demand for LNG, hydrogen, and industrial gases. Its ability to maintain ultra-low temperatures ensures safety, efficiency, and sustainability. With innovations in eco-friendly materials and expanding infrastructure, the market is poised for steady growth, supporting global energy transitions and industrial advancements.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)