Table of Contents

Overview

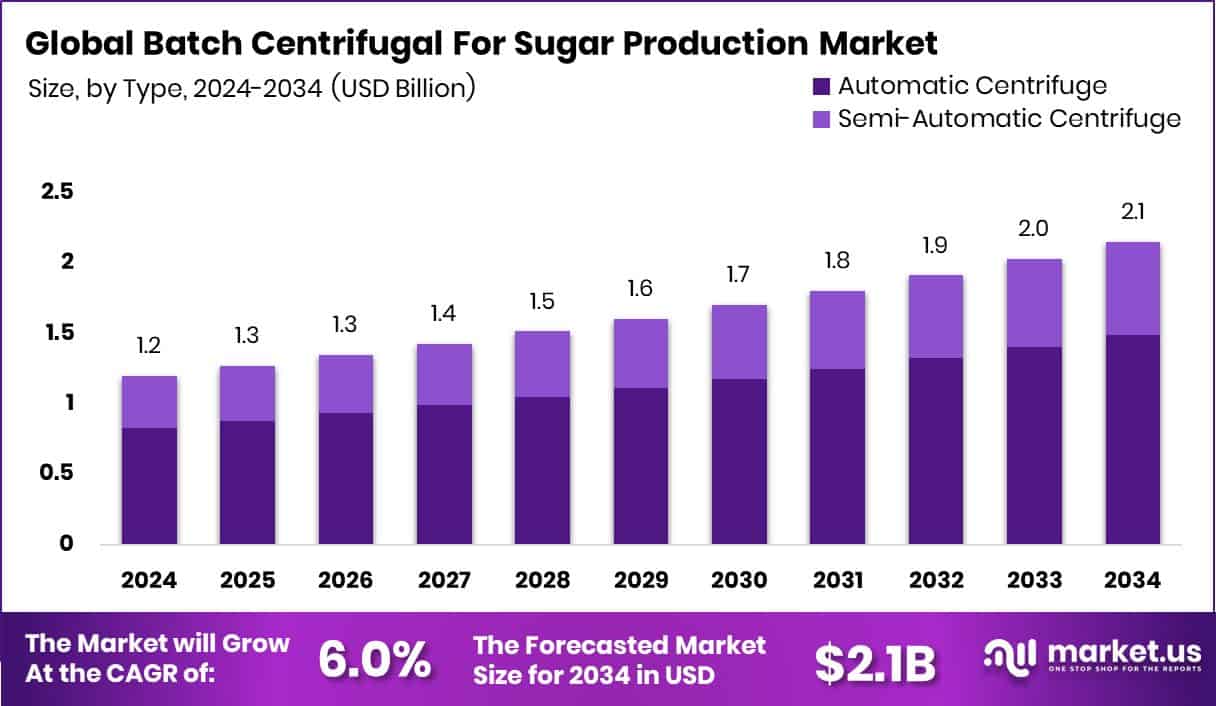

New York, NY – Nov 27, 2025 – The global batch centrifugal for sugar production market is on a steady growth path, projected to reach USD 2.1 billion by 2034, up from USD 1.2 billion in 2024, at a 6.0% CAGR between 2025 and 2034. The Asia Pacific region leads with a 41.7% share, valued at USD 0.5 billion, supported by consistent sugar manufacturing activity and upgrades in regional mills.

Batch centrifugals are essential machines in modern sugar production. They separate liquid molasses from solid sugar crystals by spinning the crystallized slurry at high speeds in controlled batches. This system allows sugar mills to achieve better crystal uniformity, lower impurity levels, and accurate moisture control. Compared with older drainage methods, batch centrifugals deliver reliable quality and higher processing efficiency, making them widely used in raw, refined, and specialty sugar operations.

Market growth is closely tied to sugar mill modernization and the rising demand for high-purity sugar in food, beverage, dairy, and bakery industries. Automation and energy-efficient processing are key priorities, encouraging mills to replace aging equipment with advanced centrifuge systems. Agricultural improvements also support demand, as solar-powered irrigation and soil recovery initiatives are expected to boost sugar output by 180,000 metric tons.

Financial backing further accelerates adoption. The Rs 750 crore AgriSure agriculture startup fund, $3 million investment in sugar substitutes, $5 million for advanced sugar processing technologies, and new refining capacity of 1.5 million metric tons per year in the UAE all enhance long-term equipment demand. Additional food-tech funding, including $25 million for dairy-free cheese innovation, strengthens diversification opportunities for sugar processing infrastructure.

➤ Click the sample report link for complete industry insights: https://market.us/report/global-batch-centrifugal-for-sugar-production-market/request-sample/

Key Takeaways

- The Global Batch Centrifugal For Sugar Production Market is expected to be worth around USD 2.1 billion by 2034, up from USD 1.2 billion in 2024, and is projected to grow at a CAGR of 6.0% from 2025 to 2034.

- In the Batch Centrifugal For Sugar Production Market, automatic centrifuges hold 68.2% share.

- Raw sugar applications account for 49.4% of the Batch Centrifugal for Sugar Production Market.

- Asia Pacific maintained 41.7% dominance, touching USD 0.5 Bn scale during the year period.

➤ Directly purchase a copy of the report – https://market.us/purchase-report/?report_id=165988

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2024) | USD 1.2 Billion |

| Forecast Revenue (2034) | USD 2.1 Billion |

| CAGR (2025-2034) | 6.0% |

| Segments Covered | By Type (Automatic Centrifuge, Semi-Automatic Centrifuge), By Application (Raw Sugar, Refined Sugar, Beet Sugar, Others) |

| Competitive Landscape | ASR Group, ANDRITZ Group, BMA Braunschweigische Maschinenbauanstalt GmbH, Buckau-Wolf GmbH, Fives Group, Guangxi Su Group Co., JBT Corporation, Tsukishima Holdings, Thomas Broadbent & Sons Ltd., Western States |

Key Market Segments

By Type Analysis

In 2024, automatic centrifuges dominated the By Type segment of the Batch Centrifugal for Sugar Production Market, capturing a 68.2% market share. Their strong adoption is mainly driven by the ability to deliver uniform sugar crystal quality while significantly reducing the need for manual intervention. These systems improve workplace safety inside sugar mills by minimizing operator exposure to high-speed and high-temperature processing conditions.

Automatic centrifuges align well with ongoing sugar mill modernization efforts, where producers focus on lower downtime, precise batch control, and effective molasses separation to meet premium sugar quality standards. Compared with manual equipment, automatic units offer consistent moisture control, quicker discharge cycles, and better hygiene management, which is critical for food-grade sugar production.

As refining requirements increase and mills aim for stable, high-volume output, automatic centrifuges continue to be favored for their reliable performance, efficient batch processing, and improved sugar recovery efficiency, reinforcing their leading position across modern sugar processing lines.

By Application Analysis

In 2024, raw sugar led the By Application segment of the Batch Centrifugal for Sugar Production Market, accounting for a 49.4% market share. This dominance is largely driven by its widespread use in large-scale sugar mills where efficient, high-volume crystallization and effective molasses separation are critical to daily operations.

Raw sugar processing depends on controlled batch cycles to achieve uniform crystal formation while preserving purity levels required for downstream refining. Both domestic consumption and export-focused mills continue to increase raw sugar output, emphasizing steady throughput and minimal processing losses.

Batch centrifugal systems play a key role by regulating moisture content, improving sugar recovery from massecuite, and supporting uninterrupted mill performance. Their ability to deliver consistent separation efficiency makes them particularly suitable for raw sugar applications, reinforcing raw sugar’s leading position in the market while meeting the operational needs of high-capacity sugar production facilities.

Regional Analysis

Asia Pacific remained the leading regional market in the Batch Centrifugal for Sugar Production Market, holding a 41.7% share valued at USD 0.5 Bn. This leadership reflects the region’s strong sugar manufacturing base, extensive plantation coverage, and ongoing modernization of sugar mills across major producing countries.

High-volume cane processing and steady demand from food and beverage industries continue to drive adoption of batch centrifugal units to improve sugar purity, crystal uniformity, and batch-level control. Factory upgrades aimed at reducing processing losses and maintaining consistent quality further strengthen regional dominance.

North America’s market activity is centered on technology-driven processing and controlled sugar quality, with automated batch centrifuges supporting industrial and packaged food applications. Europe emphasizes sustainable, high-efficiency sugar processing, investing gradually in systems that meet strict hygiene and consistency standards.

The Middle East & Africa region is gaining traction due to expanding refining capacity and rising domestic production needs. Latin America remains influential through its large plantation base and milling infrastructure, where steady adoption of batch centrifugal equipment enhances processing efficiency and crystal quality.

Top Use Cases

- Separating sugar crystals from molasses after crystallization: After sugar syrup is boiled and crystallized (forming a mixture called “massecuite”), a batch centrifugal spins that massecuite at high speed. This causes heavier molasses (liquid + impurities) to move outward through the basket walls while lighter solid sugar crystals stay inside.

- Protecting crystal integrity — minimizing breakage and improving sugar quality: Batch centrifugals are especially favored for high-grade (“A-sugar”) production because they apply gentle, controlled spinning and washing, leading to less breakage of sugar crystals.

- Efficient washing of crystals to remove residual syrup and impurities: After the main spin-out of molasses, batch centrifuges often spray the sugar crystals with water (or steam-assisted washing) to remove syrup coating and residual impurities.

- Maximizing sugar recovery and minimizing wastage/losses: Because batch centrifuges carefully separate crystals and mother liquor, they help recover a higher fraction of sugar from the massecuite.

- Flexible operation across different sugar grades (raw, refined, specialty): The batch process can be adjusted (spin speed, wash cycles, cycle duration) to match the requirements for different sugar grades — whether raw sugar for export, refined sugar for retail, or specialty sugar with specific purity/crystal size.

- Stable, repeatable batch cycles — enabling consistent mill throughput and operational control: Because each batch is processed under controlled, repeatable conditions (same spin speed, time, washing protocol), mills get consistent output quality and predictable processing times — important for planning throughput, maintenance, and overall mill scheduling.

Recent Developments

- In June 2025, ASR announced a broad optimisation of its U.S. operational network, involving acquisitions, new facility construction, expansions, and modernization of existing assets to improve efficiency, supply-chain resilience, and sustainability. As part of this, the company is combining large-scale refineries with more flexible regional production sites.

- In February 2025, ANDRITZ acquired LDX Solutions — a specialist in industrial emission-reduction technologies (wet electrostatic precipitators, thermal oxidizers, etc.).

Conclusion

The batch centrifugal for sugar production market continues to play a vital role in modern sugar manufacturing by supporting consistent quality, efficient separation, and controlled processing. These machines help sugar mills achieve better crystal purity, stable moisture levels, and reliable batch handling, which are essential for both raw and refined sugar production.

Ongoing mill modernization, rising automation, and stricter quality standards are encouraging producers to adopt advanced batch centrifuges over older mechanical systems. As sugar applications expand across food and beverage industries, the need for dependable and hygienic processing equipment remains strong.

Overall, batch centrifugal systems will remain a core component of sugar plants, supporting operational efficiency, improved product standards, and long-term sustainability in sugar processing operations.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)