Table of Contents

Overview

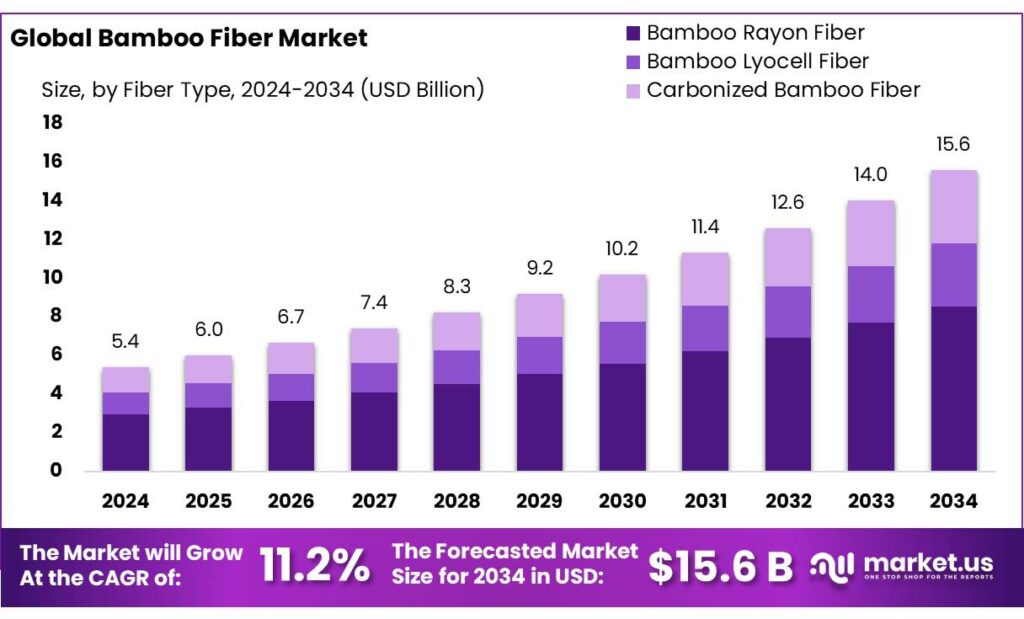

New York, NY – October 08, 2025 – The Global Bamboo Fiber Market is projected to reach around USD 15.6 billion by 2034, up from USD 5.4 billion in 2024, growing at a CAGR of 11.2% between 2025 and 2034. In 2024, Asia-Pacific dominated the market, accounting for a 48.2% share with USD 2.6 billion in revenue, highlighting its strong presence in bamboo cultivation and processing.

Bamboo fiber, extracted from the pulp of bamboo plants, is gaining prominence as a sustainable alternative to synthetic textiles. Its inherent qualities, softness, breathability, and biodegradability make it highly desirable in the textile industry. India, endowed with vast bamboo reserves, holds significant potential for bamboo fiber production, aligning with global movements favoring eco-friendly and renewable materials.

India ranks as the second-largest bamboo producer globally, generating about 14.6 million tonnes annually. However, the bamboo processing industry remains largely underdeveloped, with less than 30% of processing units mechanized, according to the Ministry of Agriculture. This gap indicates an immense opportunity for modernization and scaling up production capacities across the country.

The National Bamboo Mission (NBM), restructured in 2018, has been instrumental in strengthening bamboo cultivation and value-chain development across 24 states and union territories. As of December 2024, it has set up 408 bamboo nurseries (including 14 accredited ones) and covered 60,000 hectares of non-forest areas under bamboo plantations. Additionally, 104 bamboo treatment and preservation units have been established to promote the bamboo industry’s expansion.

In Ajara, Maharashtra, a bamboo cultivation initiative aims to enhance farmer incomes through scientific productivity improvements. Over 300 farmers participated in a workshop organized by the Institute for Social and Economic Change (ISEC) and the Indian Council of Social Science Research (ICSSR). India’s growing bamboo exports further reflect this momentum—between November 2023 and October 2024, the country exported 502 bamboo product shipments to 40 nations, with the United States accounting for 53% of total exports, showcasing the global recognition of India’s bamboo-based textiles, furniture, and handicrafts.

Key Takeaways

- Bamboo Fiber Market size is expected to be worth around USD 15.6 billion by 2034, from USD 5.4 billion in 2024, growing at a CAGR of 11.2%.

- Bamboo Rayon Fiber held a dominant market position, capturing more than a 54.8% share of the global bamboo fiber market.

- Bamboo Fiber Yarn held a dominant position in the global bamboo fiber market, capturing more than a 47.2% share.

- Textiles held a dominant market position, capturing more than a 34.6% share of the global bamboo fiber market.

- The Asia-Pacific (APAC) region held a commanding 48.2% share of the global bamboo fiber market, translating to an estimated market value of approximately USD 2.6 billion.

➤ Curious about the content? Explore a sample copy of this report – https://market.us/report/global-bamboo-fiber-market/request-sample/

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2024) | USD 5.4 Billion |

| Forecast Revenue (2034) | USD 15.6 Billion |

| CAGR (2025-2034) | 11.2% |

| Segments Covered | By Fiber Type (Bamboo Rayon Fiber, Bamboo Lyocell Fiber, Carbonized Bamboo Fiber), By Product Type (Yarn, Fabric, Nonwoven Fabric), By Application (Textiles, Apparel, Home Furnishings, Medical, Others) |

| Competitive Landscape | Aditya Birla, Red Sun Group, Sateri Group, Shanghai Aotian Bio Technology, Lenzing Group, Kelheim Fibres |

➤ Directly purchase a copy of the report – https://market.us/purchase-report/?report_id=157838

Key Market Segments

Fiber Type Analysis

Bamboo Rayon Fiber Leads with 54.8% Market Share in 2024

In 2024, Bamboo Rayon Fiber commanded the global bamboo fiber market, securing a 54.8% share. Its widespread adoption in textiles, particularly for apparel and home furnishings, drives this dominance. The production process involves chemically converting bamboo pulp into a viscous solution, which is then spun into fibers. While this method yields soft, breathable, and antibacterial fibers, it raises environmental concerns due to chemicals like carbon disulfide. Nevertheless, bamboo rayon’s desirable qualities maintain its strong market demand.

Product Type Analysis

Bamboo Fiber Yarn Holds 47.2% Market Share in 2024

Bamboo Fiber Yarn led the global bamboo fiber market in 2024, accounting for a 47.2% share. The surge in demand for sustainable, eco-friendly textiles fuels this growth, with bamboo fiber yarn’s versatility making it a preferred choice across various applications. In India, the bamboo fiber sector is expanding, supported by initiatives like the National Bamboo Mission, which promotes bamboo cultivation and its use in textiles, aligning with global sustainability trends.

Application Analysis

Textiles Capture 34.6% of the Bamboo Fiber Market in 2024

In 2024, the textile segment dominated the global bamboo fiber market with a 34.6% share, driven by rising demand for eco-friendly and sustainable fabrics. Bamboo fiber’s softness, breathability, and biodegradability make it ideal for clothing, home textiles, and industrial fabrics. Growing conscious consumerism and advancements in manufacturing processes are boosting the adoption of bamboo-based textiles. The market is poised for steady growth as brands prioritize sustainability and innovation.

Regional Analysis

Asia-Pacific Leads with 48.2% Share of Bamboo Fiber Market in 2024

The Asia-Pacific (APAC) region held a 48.2% share of the global bamboo fiber market in 2024, valued at approximately USD 2.6 billion. This leadership stems from extensive bamboo cultivation, advanced manufacturing, and strong consumer demand for sustainable products. China dominates as a global hub for bamboo fiber production, leveraging vast resources and infrastructure. India is emerging as a key player, with initiatives like the National Bamboo Mission fostering bamboo cultivation and its application in textiles and other sectors.

Top Use Cases

- Apparel Manufacturing: Bamboo fiber is widely used to create soft, breathable clothing like shirts, pants, and socks for adults and kids. Its natural antibacterial properties help fight odors and keep skin healthy, making it ideal for everyday wear. As a market research analyst, I see this use driving demand sustainably, appealing to eco-conscious buyers who want comfortable, green alternatives to synthetic fabrics.

- Home Furnishings: In bedding and towels, bamboo fiber offers moisture-wicking and hypoallergenic qualities for better sleep and hygiene. It’s perfect for sheets, pillow covers, and bath items that feel luxurious yet gentle on skin. From a market perspective, this segment grows with rising interest in home wellness products that blend comfort and environmental benefits.

- Medical Textiles: Bamboo fiber shines in non-woven fabrics for hygiene items like bandages and masks due to its inherent antimicrobial nature. It provides breathability and reduces infection risks in healthcare settings. As an analyst, I note its potential in expanding medical applications, supporting the shift toward natural, safe materials in the health and personal care industries.

- Composite Materials: For construction and furniture, bamboo fiber reinforces polymers to make durable, lightweight items like flooring and panels. Its strength rivals glass fibers while being eco-friendly. Market trends show increasing adoption in building sectors seeking sustainable reinforcements that lower costs and environmental impact without sacrificing performance.

- Automotive Interiors: Bamboo fiber composites replace plastics in car parts, offering toughness and biodegradability for dashboards and seats. This reduces vehicle weight and emissions. In my analysis, this use case highlights bamboo’s role in green transportation, aligning with industry pushes for lighter, recyclable materials to meet regulatory and consumer sustainability demands.

Recent Developments

1. Aditya Birla (Grasim Industries)

Aditya Birla, through its pulp subsidiary Grasim Industries, is focusing on expanding its sustainable viscose staple fiber (VSF) capacity, which includes fibers derived from bamboo. Their recent developments highlight the adoption of “Liva Reviva,” a premium viscose made from recycled cotton waste and sustainable wood/bamboo pulp, signaling a strong push towards a circular economy and traceable, eco-friendly textiles.

2. Red Sun Group

Red Sun Group has been actively expanding its production capacity for bamboo-based viscose staple fiber to meet growing global demand for sustainable textiles. The company focuses on integrating its manufacturing processes, from pulp to fiber, ensuring quality and environmental control. Recent reports indicate investments in cleaner, closed-loop production technologies to minimize the environmental footprint of their bamboo-derived fibers, aligning with stricter global sustainability standards.

3. Sateri Group

Sateri has made significant strides in advancing its “EcoCosy” branded fibers, which include premium viscose made from sustainably sourced bamboo and wood. A key recent development is their focus on achieving international sustainability certifications and promoting closed-loop manufacturing that recycles water and process chemicals. They are actively collaborating with fashion brands to create traceable and environmentally responsible supply chains for bamboo viscose.

4. Shanghai Aotian Bio Technology

Shanghai Aotian Bio Technology specializes in bamboo pulp and fiber production. Their recent focus has been on technological innovation to improve the quality and purity of their bamboo-based textile fibers. The company is enhancing its production efficiency and exploring new applications for bamboo fiber beyond textiles, potentially in non-woven and technical sectors, to diversify its market presence and capitalize on the material’s natural properties.

5. Lenzing Group

Lenzing is a leader in sustainable specialty fibers. Their major recent development is the launch of “TENCEL Lyocell with Refibra technology,” which now also incorporates pulp from bamboo. This innovation creates a circular fiber by upcycling cotton scraps and bamboo, offering full traceability. They are scaling production and partnering with major brands to replace conventional materials with this next-generation, sustainably produced bamboo-based lyocell.

Conclusion

Bamboo fiber stands out as a versatile, renewable material powering the shift toward eco-friendly products across textiles, construction, and beyond. Its natural softness, strength, and biodegradability meet growing consumer calls for sustainable options, fostering innovation in green manufacturing. As a market research analyst, I view its future as bright, with expanding applications that balance performance, affordability, and planetary health in a resource-conscious world.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)