Table of Contents

Overview

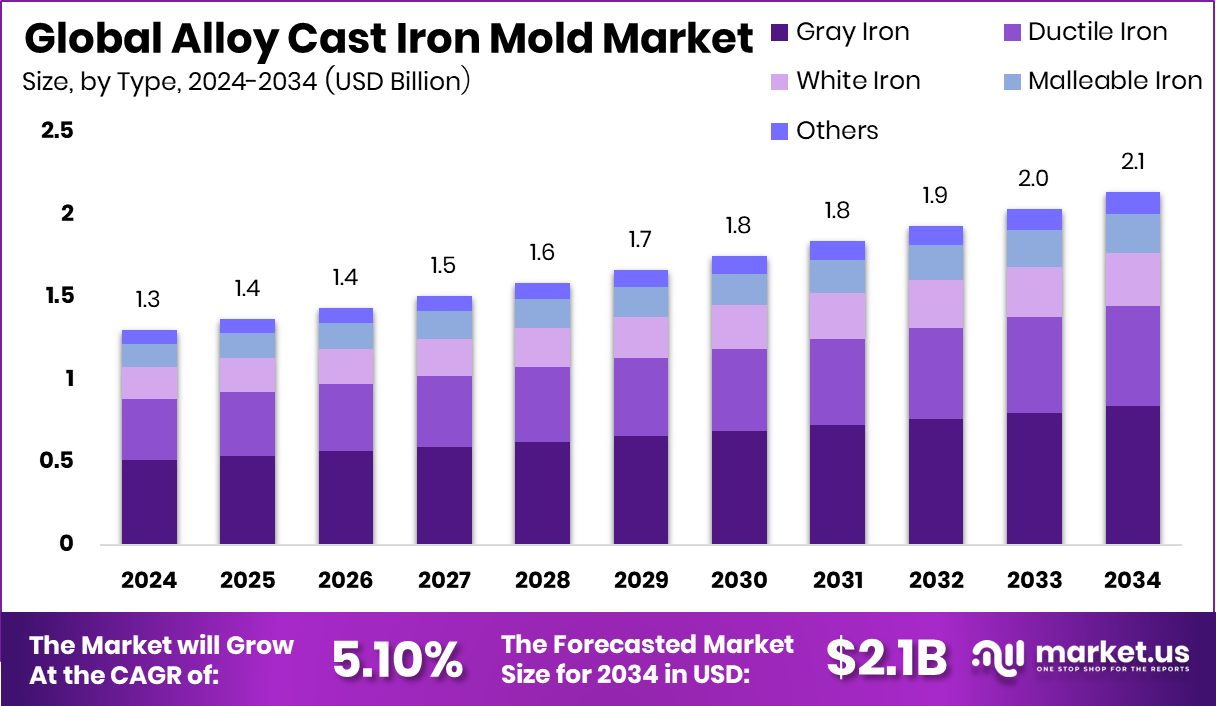

The Global Alloy Cast Iron Mold Market is projected to reach USD 2.1 billion by 2034, rising from USD 1.3 billion in 2024 at a CAGR of 5.10% from 2025 to 2034. The Asia-Pacific region remains a major contributor, holding a 41.70% share valued at USD 0.5 billion. Alloy cast iron molds—created by blending cast iron with alloying materials—offer strong heat resistance, durability, and consistent performance, making them essential for industries that rely on repeated heating, cooling, and high-pressure shaping.

Market growth is strengthened by expanding iron-processing infrastructure and cleaner production initiatives. Australia’s A$1 billion green iron fund, including A$600 million redirected toward long-term facilities, supports more sustainable mold-related ecosystems.

Similarly, BHP’s US$2 billion funding deal with GIP to enhance its iron ore power network improves supply stability and boosts mold demand indirectly. Infrastructure-driven projects such as ACIPCO’s proposed USD 185 million investment and EGLE’s USD 65.9 million clean water grants increase the need for cast iron components, reinforcing mold usage in large-scale manufacturing.

Emerging opportunities come from private investments and specialty product segments. Allana Group’s USD 10 million investment in Iron Pillar Fund II, along with rising funding for toxin-free kitchenware—including USD 1.5 million and INR 23.1 crore rounds—signals growing demand for durable, high-quality cast items produced using reliable alloy cast iron molds.

Top Key Players in the Market

- Hitachi Metals Ltd.

- Thyssenkrupp AG

- Dandong Foundry

- Waupaca Foundry, Inc.

- Metal Technologies, Inc.

- Eisenwerk Brühl GmbH

- OSCO Industries, Inc.

- Aarrowcast, Inc.

- Denison Industries

- Benton Foundry, Inc

1. Hitachi Metals Ltd.

Hitachi Metals Ltd. is a major provider of high-function materials, serving industries such as automotive, electronics, and industrial machinery. The company specializes in advanced materials, including specialty steels, magnetic materials, and cast components designed for high performance. Its long-standing manufacturing expertise helps deliver reliable solutions for global clients.

The company’s continued focus on research and material innovation supports the development of next-generation products used in electric mobility and modern industrial systems. Hitachi Metals operates multiple production and R&D facilities worldwide, ensuring high service quality and operational efficiency across its customer base.

| Attribute | Details |

|---|---|

| Company Name | Hitachi Metals Ltd. |

| Established | 1956 |

| Headquarters | Tokyo, Japan |

| Industry | Specialty Metals & Materials |

| Products | Specialty steels, magnetic materials, cast components |

| Employees | 8,288 |

| Main Markets | Automotive, industrial |

| Business Type | Global materials manufacturer |

| Global Presence | Multiple countries |

| R&D Focus | Advanced material technologies |

2. Thyssenkrupp AG

Thyssenkrupp AG is a diversified global industrial group offering solutions in automotive technologies, decarbonization systems, materials services, and engineering. The company invests heavily in innovation, producing high-value industrial products aimed at improving energy efficiency and supporting industrial transformation.

With a large global footprint, Thyssenkrupp operates across dozens of countries and collaborates with major industries worldwide. Its business model emphasizes sustainable production, research, and responsible manufacturing, supported by a large workforce and extensive patent portfolio.

| Attribute | Details |

|---|---|

| Company Name | Thyssenkrupp AG |

| Headquarters | Essen & Duisburg, Germany |

| Industry | Industrial Engineering |

| Revenue | €33 Billion (Approx.) |

| Employees | 93,000 |

| Key Segments | Automotive, steel, marine systems |

| Business Focus | Industrial tech & engineering |

| Patent Portfolio | 17,000+ |

| R&D Staff | 3,900 |

| Global Reach | 48+ countries |

3. Waupaca Foundry, Inc.

Waupaca Foundry is a major producer of ductile and gray iron castings, supplying the automotive, agriculture, and industrial equipment sectors. The company is known for high-volume production capabilities and robust quality standards supported by advanced materials engineering.

Its operations span multiple U.S. locations, ensuring a reliable supply chain for customers. Waupaca’s strong manufacturing foundation and integration with advanced technologies allow it to remain a leader in delivering engineered cast-iron products.

| Attribute | Details |

|---|---|

| Company Name | Waupaca Foundry, Inc. |

| Headquarters | Waupaca, Wisconsin, USA |

| Industry | Iron Foundry |

| Products | Gray & ductile iron castings |

| CEO | Gary Gigante |

| Employees | 3,900 |

| Key Markets | Automotive, industrial |

| Ownership | Hitachi Metals Group |

| Plant Locations | WI, TN, IN |

| Business Type | High-volume casting producer |

4. OSCO Industries, Inc.

OSCO Industries is one of the oldest gray iron foundries in the United States, serving industrial, automotive, and HVAC markets. Its operations include multiple manufacturing facilities in Ohio, each focused on producing consistent, precision-engineered cast iron components.

The company emphasizes product reliability and craftsmanship supported by over a century of foundry expertise. OSCO’s long history and multi-plant operations underscore its strong manufacturing capability and long-term industry relationships.

| Attribute | Details |

|---|---|

| Company Name | OSCO Industries, Inc. |

| Established | 1872 |

| Headquarters | Portsmouth, Ohio, USA |

| Industry | Gray Iron Foundry |

| Products | Gray iron castings |

| Facilities | Portsmouth, New Boston, Jackson |

| Plant Size | 110,000 sq ft (Portsmouth) |

| Markets Served | HVAC, automotive, industrial |

| Experience | 150+ years |

| Workforce | 200+ employees |

5. Metal Technologies, Inc.

Metal Technologies, Inc. is a family-owned casting and machining company serving automotive, agriculture, and industrial sectors. The company provides engineered ductile and gray iron components produced through advanced foundry systems.

With multiple facilities across the U.S. and Mexico, MTI supports a wide industrial customer base and focuses on sustainability with modern melting operations and energy-efficient technologies.

| Attribute | Details |

|---|---|

| Company Name | Metal Technologies, Inc. |

| Industry | Metal Casting & Machining |

| Products | Gray iron, ductile iron, machining services |

| Locations | U.S. & Mexico |

| Business Type | Family-owned |

| Services | Casting, machining, engineering |

| Market Focus | Automotive, commercial, industrial |

| Sustainability | Carbon-neutral casting initiatives |

| Manufacturing Capability | High-volume production |

| Technology | Advanced melt processes |

6. Dandong Foundry

Dandong Foundry specializes in gray iron, ductile iron, and steel castings for machinery, automotive parts, and custom industrial applications. The company offers casting, machining, and surface treatment services with a focus on tailored production according to client specifications.

With long-term expertise and a diverse product portfolio, the company supports domestic and international customers through flexible production and consistent quality standards.

| Attribute | Details |

|---|---|

| Company Name | Dandong Foundry |

| Industry | Iron & Steel Casting |

| Products | Gray iron, ductile iron, steel castings |

| Capabilities | Casting, machining, surface treatment |

| Market Focus | Industrial & automotive |

7. Eisenwerk Brühl GmbH

Eisenwerk Brühl GmbH is a German foundry specializing in high-quality cast iron components for automotive engine systems. Its expertise includes cylinder blocks and precision castings for major global manufacturers.

The company emphasizes advanced production technology and strict quality control, supporting long-term partnerships with leading automotive OEMs.

| Attribute | Details |

|---|---|

| Company Name | Eisenwerk Brühl GmbH |

| Industry | Automotive Casting |

| Products | Engine blocks, precision castings |

| Market Focus | Automotive OEMs |

| Expertise | High-precision casting |

8. Aarrowcast, Inc.

Aarrowcast, Inc. is a U.S. foundry producing ductile and gray iron castings for heavy equipment, agriculture, and industrial customers. The company provides comprehensive casting solutions with advanced molding and melting systems.

Its facilities support both medium and high-volume casting projects, ensuring production flexibility and consistent material quality.

| Attribute | Details |

|---|---|

| Company Name | Aarrowcast, Inc. |

| Industry | Iron Foundry |

| Products | Ductile & gray iron castings |

| Market Focus | Agriculture, heavy equipment |

| Capabilities | Advanced molding & melting |

9. Denison Industries

Denison Industries is a precision casting and machining company serving aerospace, defense, and industrial sectors. The company produces high-reliability components with advanced materials and processes tailored to specialized applications.

Its capabilities include high-grade casting, heat treatment, machining, and inspection services designed to meet stringent customer specifications.

| Attribute | Details |

|---|---|

| Company Name | Denison Industries |

| Industry | Precision Casting |

| Products | Aerospace & defense castings |

| Capabilities | Casting, machining, heat treatment |

| Applications | Aerospace, defense, industrial |

10. Benton Foundry, Inc.

Benton Foundry, Inc. is a high-performance casting company specializing in gray and ductile iron components. Serving a wide range of industries, the company is known for its modern foundry operations and strong engineering support.

Its facilities incorporate advanced automation and melting systems, ensuring consistent quality and high-efficiency production for commercial and industrial customers.

| Attribute | Details |

|---|---|

| Company Name | Benton Foundry, Inc. |

| Industry | Iron Casting |

| Products | Gray & ductile iron castings |

| Market Focus | Industrial & commercial |

| Capabilities | Automated molding & melting |

Conclusion

Alloy cast iron molds used in phosphite-related applications play a vital role in ensuring stable, reliable, and consistent production processes. Their enhanced strength, heat resistance, and wear durability make them well-suited for demanding chemical and industrial environments where repeated thermal cycles and pressure are common. These molds support precise shaping and uniform quality, helping manufacturers reduce defects, downtime, and maintenance needs.

As industries continue to emphasize efficiency, safety, and cleaner production practices, alloy cast iron molds remain a dependable solution. Their long service life and adaptability across industrial uses reinforce their importance in supporting sustainable manufacturing and long-term operational performance.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)