Table of Contents

Introduction

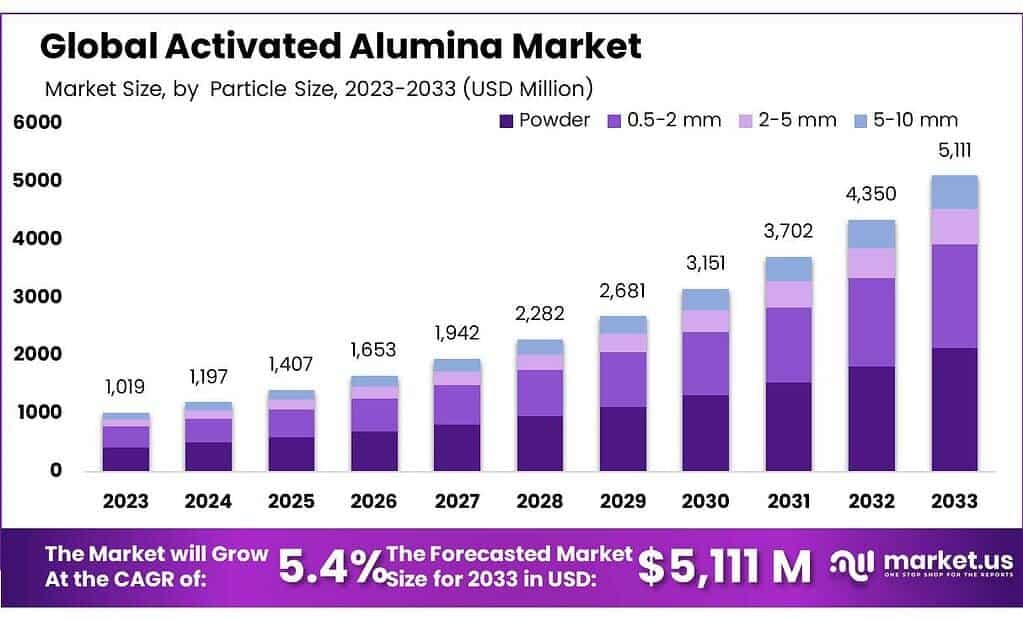

The global Activated Alumina Market is experiencing steady growth and is projected to reach a value of approximately USD 5111 Million by 2033, up from USD 1,018.9 Million in 2023. The market will expand at a compound annual growth rate (CAGR) of 5.4% from 2023 to 2033.

Activated Alumina, a versatile material used in applications such as water treatment, air purification, and the petroleum industry, is gaining significant demand due to its high absorption and desiccant properties. Key growth drivers include the increasing need for water purification systems and air treatment solutions, driven by rising environmental concerns and stricter regulations.

Moreover, the growing demand for activated alumina in the petroleum refining sector contributes to market expansion. The popularity of this material is also rising across industries such as chemicals, pharmaceuticals, and food and beverages, where it is used in various applications, including as a drying agent and catalyst support.

Additionally, there are several market opportunities arising from emerging economies, where the demand for water treatment solutions and industrial air purification is growing rapidly. The market is also seeing increased investment in research and development, which is leading to innovations in activated alumina production processes and enhancing its efficiency and cost-effectiveness.

With increasing environmental awareness and an expanding industrial base, the activated alumina market is expected to continue its growth trajectory, offering new opportunities for key players and investors in the coming years.

Key Takeaways

- Market Growth Projection: The global activated alumina market is estimated to grow from USD 1018.9 Million in 2023 to approximately USD 5111 Million by 2033, marking a CAGR of 5.4% during this period.

- Particle Size Variants: Different particle sizes cater to specific industry needs. Segments like powder, 0.5-2 mm, 2-5 mm, and 5-10 mm serve varied purposes, offering specific characteristics and suitability for different applications.

- Asia Pacific is expected to dominate the global Activated Alumina market in 2023, accounting for 36% of the total revenue.

Activated Alumina Statistics

- The specific surface area, pore diameter, and pore volume of the activated alumina were measured using the Brunauer–Emmett–Teller (BET) test and were 334.67 m2/g, 8.096 nm, and 0.0713 cm3/g, respectively.

- This reaction can result in the production of a highly porous material with a surface area of more than 200 m2/g.

- It is discovered that the alumina chemical reaction capability ranges from 3 mg/g in alkaline water to 20 mgF/g in acidic water.

- Two percent hydrochloric acid, 2 percent sodium hydroxide, or 1 percent sulfuric acid could renew the saturated medium.

- Activated alumina’s entire surface area, which ranges from 500 to 2000 m2.

- Their findings demonstrated that, with a regulated pH of 8.5 and a reaction temperature of 70°C, a stable gamma alumina could be produced in a high yield and with a high specific surface area.

- The pH affects how well-activated alumina works. Water should generally have a pH of less than 8.5.

- Chromium is present in analyses of the various grades of activated alumina, but at far lower concentrations than would be required for RMIC values based on a maximum use of 2 g/liter of water.

- The cost of making one t of alumina using the dross process is USD 130.01, which is only 49.54% of the cost of making bauxite.

- the biggest producer of aluminum in the world. Over 40 kg of aluminum dross are produced in the production of 1 t of aluminum.

- In a reactor, 99.9% pure aluminum and aqueous NaOH interacted at room temperature to form a sodium aluminate (NaAlO2) solution.

- A mineral adsorbent with high porosity and strength is Al2O3 active alumina. This substance is created by heating alumina (Al2O3).

- because liquid water causes silica gel to shatter. On the desiccant bed’s intake side, it needs to be shielded by a layer of activated alumina that is 10% to 15% (by weight) thick as a water buffer.

- Using a Bayer aluminum hydroxide with a grain diameter in the 50%> range (d50) of 30 μm to 150 μm is the method described in claim 1.

- Granular activated alumina doped with phosphorus can be obtained by following any of claims 1 through 11.

- Claim 15 describes a granular phosphorus-doped activated alumina with an average particle size in the 50% range (d50) of 0.5 to 1.0 mm.

- Use of the phosphorus-doped activated alumina as a pH buffer in plant growing media, ideally in potted plants, as stated in claims 12 or 15.

- The grain diameter of 90 weight percent of activated phosphorus-doped alumina granules is typically less than 1.25 mm.

Emerging Trends

- Rise in Water Treatment Demand: Activated alumina’s role in water purification is growing as global water scarcity issues become more pronounced. Its high adsorption capacity makes it ideal for removing fluoride, arsenic, and other contaminants, leading to increased adoption in water treatment plants worldwide.

- Growing Use in Air Purification: With rising air pollution levels, activated alumina is becoming a preferred material for air purification systems. It is used in the removal of moisture and pollutants from compressed air, and gas streams, and in the treatment of air in industrial processes.

- Advancements in Production Technology: New manufacturing techniques are improving the efficiency and cost-effectiveness of activated alumina. Innovations in production methods are reducing energy consumption and increasing the material’s performance, making it more attractive for industrial applications.

- Increased Adoption in Pharmaceuticals: Activated alumina is finding growing use in the pharmaceutical industry, where it is used for drying gases, liquids, and solvents. Its use in drug manufacturing and storage is increasing as pharmaceutical companies focus on improving product quality and shelf life.

- Sustainability Focus: With increasing environmental awareness, the demand for eco-friendly and recyclable materials is rising. Activated alumina, being non-toxic and reusable, is gaining popularity as a sustainable solution in water and air purification, as well as in industrial processes.

- Expanding Applications in the Petroleum Industry: The petroleum industry is a key consumer of activated alumina, used in refinery processes such as desulfurization and hydrogenation. As refining technologies evolve, activated alumina’s role in enhancing efficiency and product quality is becoming more significant.

- Growing Market in Developing Economies: Developing regions, particularly in Asia-Pacific and Africa, are experiencing rapid industrialization and urbanization, leading to increased demand for water treatment and air purification solutions. This is driving the market for activated alumina in these regions.

- Shift Towards High-Performance Activated Alumina: There is a growing preference for high-performance activated alumina products that offer enhanced adsorption properties and longer lifespan. This shift is driven by industries seeking more cost-effective and reliable solutions for water, air, and industrial gas treatment.

- Use in Chemical and Petrochemical Industry: Activated alumina is increasingly used in the chemical and petrochemical industries for catalysts and adsorbents. Its ability to support catalytic reactions and selectively adsorb specific compounds is boosting its application in these high-growth sectors.

Use Cases

- Water Fluoridation and Decontamination: Activated alumina is widely used in water treatment to remove fluoride, arsenic, and other toxic contaminants. Its high adsorption properties make it ideal for purifying drinking water, especially in areas with high levels of fluoride or heavy metals in the water supply.

- Gas and Air Drying: Activated alumina is an effective desiccant used in drying gases and air. It is commonly used in natural gas processing, refrigeration, and air conditioning systems to remove moisture, preventing corrosion and improving the performance of equipment.

- Catalyst Support in Petroleum Refining: In the petroleum industry, activated alumina serves as a catalyst support in refining processes such as hydrocracking and catalytic reforming. Its high surface area and thermal stability help improve the efficiency of refining operations and the quality of refined products.

- Pharmaceutical Drying Applications: Activated alumina is used in the pharmaceutical industry for drying gases and liquids, especially in processes that require the removal of moisture to maintain product integrity. It is also employed in drug storage to control moisture levels and prevent the degradation of sensitive compounds.

- Desulfurization in Gas Processing: Activated alumina is used for desulfurization in natural gas and oil processing. It adsorbs sulfur compounds, improving the quality of the gas and meeting regulatory standards for sulfur content in fuels, ensuring environmental compliance and reducing corrosive effects on machinery.

- Battery Manufacturing: Activated alumina is used in the manufacturing of batteries, particularly in the production of lithium-ion batteries. It helps improve the efficiency of the battery’s charging and discharging cycles by enhancing its overall stability and longevity.

- Drying of Solvents in Chemical Manufacturing: Activated alumina is widely used in the chemical industry to dry solvents and gases. Its high surface area and moisture-absorbing capacity make it ideal for removing water from organic compounds, ensuring the purity and stability of chemicals during production and storage.

- Separation of Liquid Hydrocarbons: In oil and gas applications, activated alumina is used to separate liquid hydrocarbons from gas streams. Removing moisture and sulfur compounds helps optimize the performance of pipelines and reduces the risk of corrosion and clogging, leading to improved operational efficiency.

- Removal of Acid Gases in Petrochemical Processes: Activated alumina is utilized in the petrochemical industry for the removal of acid gases such as hydrogen sulfide (H2S) and carbon dioxide (CO2). This process, known as gas sweetening, is crucial for ensuring the quality of natural gas and preventing pipeline corrosion.

Major Challenges

- Limited Regeneration Capacity: One of the major challenges of activated alumina is its limited regeneration ability. Over time, it loses its efficiency after repeated use, especially in high-moisture or high-contaminant environments. This necessitates frequent replacement or costly regeneration processes, increasing operational costs.

- Sensitivity to Temperature and Humidity: Activated alumina’s performance can be impacted by extreme temperatures and humidity levels. In environments with fluctuating conditions, its adsorption efficiency may degrade, reducing its effectiveness in applications like air and gas drying, and requiring more frequent monitoring and maintenance.

- High Initial Cost: The cost of activated alumina can be relatively high, particularly for high-purity grades used in specialized applications like pharmaceuticals or advanced water treatment. This initial investment can be a barrier for small and medium-sized enterprises, especially in emerging markets with limited budgets.

- Dust Formation During Handling: Activated alumina is prone to dust formation during manufacturing, handling, and transportation. This can lead to environmental concerns and pose a risk to worker safety. Dust inhalation can also impact the material’s performance, especially when it is used in sensitive applications such as in medical or food industries.

- Contamination from Impurities: In some cases, activated alumina can be contaminated with impurities during production, storage, or transportation. These contaminants can reduce its adsorption efficiency and affect the quality of the processes it is used in, particularly in water treatment and air purification applications.

- Regulatory Compliance Challenges: As environmental regulations become more stringent, manufacturers of activated alumina must continuously ensure that their products meet evolving standards. This can require significant investment in research, testing, and certification processes, creating challenges for producers trying to stay competitive while complying with local regulations.

- Limited Adsorption Capacity for Certain Contaminants: Activated alumina may not be effective for adsorbing all types of contaminants, particularly heavy metals or some complex organic compounds. Its adsorption capacity is limited to specific substances, which can restrict its use in some specialized water and air purification applications.

- Environmental Disposal Concerns: After use, activated alumina can become saturated with contaminants, raising concerns about its disposal. If not regenerated properly, the material may pose environmental risks, especially in large-scale applications. Safe and environmentally responsible disposal or recycling methods are essential but can be costly and complex.

- Competition from Alternative Materials: Activated alumina faces growing competition from alternative materials like silica gel, molecular sieves, and synthetic zeolites. These materials can sometimes offer similar or better performance in specific applications, posing a challenge for activated alumina’s market share, especially in industries seeking cost-effective solutions.

Market Growth Opportunities

- Expansion in Emerging Markets: As industrialization accelerates in emerging economies, the demand for activated alumina in water treatment, air purification, and petroleum refining is rising. Countries with growing populations and environmental concerns provide significant opportunities for market expansion, driving increased adoption of activated alumina.

- Rising Demand for Water Purification: With global water scarcity becoming a critical issue, there is growing demand for effective water purification technologies. Activated alumina’s ability to remove harmful contaminants like fluoride and arsenic positions it as a key material for addressing water quality challenges in developing regions.

- Government Regulations and Environmental Initiatives: Stricter environmental regulations and sustainability initiatives worldwide are increasing the demand for activated alumina in air and water purification applications. As industries face tighter emission and contamination standards, activated alumina can play a crucial role in meeting regulatory compliance, offering growth opportunities.

- Technological Advancements in Regeneration Processes: Ongoing innovations in regeneration technology can extend the lifespan of activated alumina, making it more cost-effective for long-term use. Improved regeneration techniques could increase market adoption in sectors such as water treatment, air filtration, and petroleum refining, opening up new growth avenues.

- Increased Usage in Healthcare and Pharmaceuticals: The pharmaceutical industry’s growing need for moisture control and air filtration provides new opportunities for activated alumina. Its use in drying gases, solvents, and controlled environments can help improve drug manufacturing processes, offering significant growth prospects in healthcare and pharmaceuticals.

- Sustainability and Eco-Friendly Applications: Activated alumina is gaining traction due to its recyclable and non-toxic nature, making it an attractive option for companies focused on sustainable practices. As industries shift towards greener alternatives, activated alumina’s eco-friendly benefits offer new growth opportunities in various sectors.

- Growth in Industrial Applications: Activated alumina is becoming increasingly essential in various industrial processes, including chemicals, petrochemicals, and gas processing. Its role in catalysis, desulfurization, and drying applications is expanding as industries look for more efficient and sustainable materials, creating significant opportunities for market growth.

- Focus on Sustainable Solutions: As industries and consumers seek more sustainable products, activated alumina’s eco-friendly properties make it an attractive option. Its reusable and non-toxic nature positions it well for growth, particularly as companies adopt greener alternatives to traditional filtration and drying materials.

- Adoption in Air Quality Control: With growing concerns about air pollution and indoor air quality, activated alumina is increasingly being used in air purification systems, particularly in HVAC systems, industrial ventilation, and personal air filtration devices. This rising trend in air quality control opens up new market opportunities.

- Growth in Oil and Gas Sector: The oil and gas industry’s continuous need for effective moisture and sulfur removal in natural gas processing, refining, and storage creates a strong market opportunity for activated alumina. As exploration and production activities increase, so will the demand for high-performance filtration solutions.

Recent Development

- BASF SE is a global leader in the production of activated alumina, providing solutions for air and water purification, petrochemical processes, and other industrial applications. The company’s advanced materials are known for their high efficiency in moisture removal, desulfurization, and catalysis, helping industries meet environmental regulations.

- Honeywell International Inc. is a prominent player in the activated alumina market, offering high-performance materials used in air purification, water treatment, and gas processing. Their activated alumina products are integral to various industrial applications, particularly in refining and petrochemical industries, supporting sustainability and efficiency goals.

- Sumitomo Chemical Co. Ltd manufactures activated alumina products primarily used for drying and purification applications in industries such as chemicals, petrochemicals, and water treatment. The company’s solutions are widely recognized for their superior moisture adsorption capacity, making them ideal for use in demanding industrial environments.

- Axens is a leader in catalytic solutions and chemical technologies, providing activated alumina for oil refining, natural gas treatment, and environmental applications. Their high-quality activated alumina products are used to remove contaminants and improve process efficiency, supporting sustainable practices across multiple industries.

- AGC CHEMICALS PVT. LTD. specializes in activated alumina production for a wide range of applications, including air and water purification, industrial drying, and as a catalyst support material. The company’s products are known for their durability and effectiveness, meeting the needs of industries such as chemicals and petrochemicals.

- Sorbead India manufactures and supplies activated alumina to various industries, including water treatment, air purification, and oil refining. Their products are designed for high moisture adsorption capacity and long-lasting performance, supporting industries in achieving efficient filtration and contamination control.

- Shandong Zhongxin New Material Technology Co. Ltd. This Chinese company produces activated alumina primarily for water treatment, industrial drying, and gas purification. Known for its cost-effective solutions, Shandong Zhongxin focuses on providing high-quality, reliable activated alumina that meets the growing demands of both domestic and international markets.

- Luoyang Xinghua Chemical Co. Ltd. specializes in the production of activated alumina for applications in water treatment, oil refining, and air purification. Their products are known for their high adsorption efficiency, offering effective solutions for removing contaminants and improving the quality of water and gases.

- Sialca Industries manufactures activated alumina primarily used in water treatment and air purification applications. Their products are designed to provide high adsorption capacity for contaminants such as fluoride and arsenic, addressing critical environmental and health concerns in both industrial and residential settings.

- Shayan Corporation produces high-quality activated alumina for use in water filtration, air purification, and chemical processes. Their products are widely used for moisture removal, pollutant adsorption, and gas drying, meeting the needs of industries such as chemicals, pharmaceuticals, and food processing.

- BeeChems focuses on producing activated alumina used in industrial gas and liquid purification, particularly for moisture removal and catalysis. Known for their high-performance materials, BeeChems supports industries such as petrochemicals, water treatment, and pharmaceuticals with cost-effective and reliable activated alumina solutions.

- Hengye Inc. manufactures activated alumina for a wide range of applications, including air and gas drying, water purification, and in the petroleum industry. Their products are known for their high absorption capacity and efficiency, helping industries meet environmental standards and improve operational performance.

- Huber Engineered Materials produces activated alumina for air and water purification, industrial drying, and catalyst support applications. Their products are used across various industries, including petrochemicals, chemicals, and food and beverage processing, providing efficient, environmentally friendly solutions for moisture and contaminant removal.

Conclusion

In conclusion, the Activated Alumina Market is poised for steady growth, driven by increasing demand across various industries, including water treatment, air purification, petroleum refining, and pharmaceuticals. The material’s superior adsorption properties, cost-effectiveness, and versatility make it a critical component in many applications. As environmental regulations become stricter and industrial needs evolve, activated alumina’s role in meeting these demands will continue to expand.

However, challenges such as limited regeneration capacity and competition from alternative materials may hinder growth in some sectors. Nonetheless, technological advancements, growing awareness of sustainability, and new applications in emerging markets present significant opportunities for further market expansion. With ongoing innovations and the rising focus on environmental sustainability, activated alumina is well-positioned to remain a key player in various industrial applications in the years to come.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)