Table of Contents

Overview

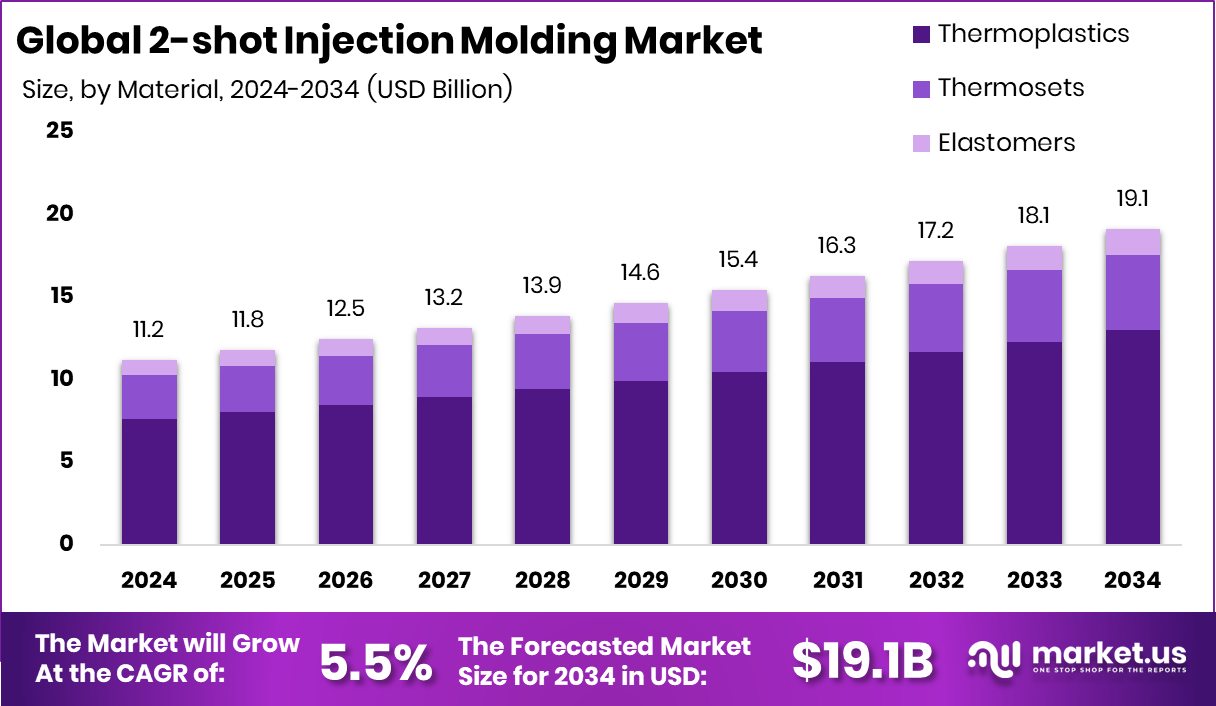

New York, NY – December 26, 2025 – The global 2-shot injection molding market is on a steady growth path, supported by rising demand for advanced, multi-material manufacturing solutions. The market is projected to expand from USD 11.2 billion in 2024 to around USD 19.1 billion by 2034, registering a CAGR of 5.5% between 2025 and 2034. North America leads global adoption, holding a 44.80% share, equivalent to approximately USD 5.0 billion, driven by strong industrial automation, automotive innovation, and high-value product design.

2-shot injection molding enables two different materials or colors to be formed into a single component within one production cycle. This approach enhances material bonding, reduces secondary assembly steps, and improves both product durability and visual quality. As manufacturers prioritize lightweight structures, compact designs, and production efficiency, this process is becoming a preferred choice across automotive, electronics, medical, and consumer goods sectors.

Market expansion is closely tied to investments in next-generation materials. Lignin Industries raised €3.9 million to commercialize bio-based thermoplastics, supporting sustainable material integration into advanced molding. In parallel, the Spokane Aerospace Materials Manufacturing Center Tech Hub received $48 million in federal support, strengthening high-performance materials infrastructure.

Demand is further reinforced by circular and waste-derived materials. UBQ Materials secured $70 million for waste-based thermoplastics, while Strohm raised €15 million and an additional $30.86 million to scale thermoplastic composite pipe production. These funding flows highlight long-term opportunities for 2-shot injection molding in sustainable, multi-material product development.

➤ Click the sample report link for complete industry insights: https://market.us/report/global-2-shot-injection-molding-market/request-sample/

Key Takeaways

- The Global 2-shot Injection Molding Market is expected to be worth around USD 19.1 billion by 2034, up from USD 11.2 billion in 2024, and is projected to grow at a CAGR of 5.5% from 2025 to 2034.

- Thermoplastics lead the 2-shot injection molding market with a 67.9% share due to their flexibility and recyclability.

- Horizontal machines dominate the 2-shot injection molding market, holding a 55.3% share for production efficiency.

- Automotive leads the 2-shot injection molding market with a 38.5% application share worldwide.

- In North America, the 2-shot Injection Molding Market reached USD 5.0 Bn, holding 44.80%.

➤ Directly purchase a copy of the report – https://market.us/purchase-report/?report_id=169509

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2024) | USD 11.2 Billion |

| Forecast Revenue (2034) | USD 19.1 Billion |

| CAGR (2025-2034) | 5.5% |

| Segments Covered | By Material (Thermoplastics, Thermosets, Elastomers), By Machine Type (Horizontal, Vertical, Rotary), By Application (Automotive, Healthcare, Consumer Electronics, Packaging, Others) |

| Competitive Landscape | Arburg GmbH + Co KG, Bemis Manufacturing Company, Biomedical Polymers Inc, CM International Industries Corporation, ENGEL Holding GmbH, Girard Rubber Corporation, Haitian International Holdings Limited, Husky Injection Molding Systems Ltd., KraussMaffei Group GmbH, Milacron LLC |

Key Market Segments

By Material Analysis

In 2024, Thermoplastics held a dominant market position in the By Material segment of the 2-shot Injection Molding Market, with a 67.9% share. This leadership reflects the strong processing flexibility and repeatability that thermoplastics offer in two-shot molding operations.

Manufacturers prefer thermoplastics due to their ability to bond efficiently in multi-material cycles while maintaining dimensional stability and surface quality. The material supports complex geometries and dual-function parts without secondary assembly, improving production efficiency. Its compatibility with automated molding systems further strengthens adoption across high-volume manufacturing environments.

Thermoplastics also allow easier recycling and reprocessing during molding, reducing material loss. In 2-shot injection molding, consistent melt flow and predictable cooling behavior enable stable cycle times, making thermoplastics a reliable choice. As product designs increasingly require soft-touch surfaces, rigid structures, or layered performance, thermoplastics continue to anchor material selection within this segment.

By Machine Type Analysis

In 2024, Horizontal held a dominant market position in the By Machine Type segment of the 2-shot Injection Molding Market, with a 55.3% share. This dominance is linked to the machine’s stable clamping structure and flexibility in handling complex two-material molds.

Horizontal machines support precise alignment between shots, which is essential for consistency and strong material bonding. Their layout allows easier mold changes and smoother automation integration, supporting continuous production cycles. Manufacturers rely on horizontal configurations for better control over injection pressure and cooling balance during multi-shot operations.

The design also enables efficient material flow and accurate shot transfer without compromising part quality. As demand grows for multi-material components with tight tolerances, horizontal machines remain the preferred choice within this segment due to their operational reliability and proven performance.

By Application Analysis

In 2024, Automotive held a dominant market position in By Machine Type segment of the 2-shot Injection Molding Market, with a 38.5% share. This leadership is driven by the automotive sector’s need for multi-material parts that combine strength, flexibility, and visual appeal in a single component.

Two-shot molding supports the production of interior and exterior parts that require tight tolerances and durable bonding between materials. Automotive production environments favor this process for its ability to reduce assembly steps while improving part consistency. The process also supports lightweight component design, which aligns with efficiency and performance goals.

High repeatability and design precision make two-shot molding well-suited for automotive applications, allowing manufacturers to meet strict quality standards while maintaining production speed and design flexibility.

Regional Analysis

North America leads the 2-shot Injection Molding Market with a 44.80% share, valued at USD 5.0 billion, supported by early adoption of advanced manufacturing technologies and strong demand for precision, multi-material components. High automation levels and consistent quality requirements reinforce large-scale implementation across key industries.

Europe represents a mature and stable market, where structured manufacturing systems and strict compliance standards favor two-shot injection molding. The region focuses on durability, process efficiency, and high-performance components, making this technology well aligned with industrial production needs.

Asia Pacific is gaining strong momentum as manufacturing capacity expands and technology adoption accelerates. Rising industrial output and demand for value-added plastic components are driving wider use of multi-material molding across regional production hubs.

The Middle East & Africa market is developing steadily, supported by growing industrial infrastructure and increasing interest in advanced plastics processing to improve product durability.

Latin America shows gradual adoption, driven by the modernization of manufacturing facilities and growing awareness of efficiency-focused molding techniques.

Top Use Cases

- Automotive Interior Parts: 2-shot injection molding is commonly used to make car interior pieces like dashboard buttons, steering wheel controls, and armrest trims. These parts often need hard plastic for structure and softer material for grip or comfort — all in one piece without extra assembly.

- Consumer Electronics Components: This process is ideal for producing electronic parts such as smartphone cases, remote control buttons, and power switches. Manufacturers combine rigid plastic for strength with softer or colored sections for a better feel and appearance.

- Soft-Grip Handles and Tools: Everyday handles, like those on toothbrushes or hand tools, benefit from two different materials. A hard plastic core gives shape while a soft outer layer gives comfort and prevents slipping.

- Household Appliance Parts: Many home appliances — like kitchen or laundry devices — use multi-material parts. For example, knobs and switches that need a solid structure plus a comfortable touch are made with two-shot molding.

- Toys and Recreational Products: Toys often combine bright colors and different textures in one piece. 2-shot injection molding lets makers insert flexible or colored parts directly into toys without sticking pieces together later.

Recent Developments

- In March 2024, Arburg introduced a new electric injection molding machine called the ALLROUNDER 720E Golden Electric at NPE2024 in Orlando, USA. This machine offers high precision molding, a compact design, and flexibility for automation, making it ideal for producing technical parts.

- In May 2024, ENGEL announced that it was reorienting its global business and adding production capacity in Mexico, expanding its manufacturing footprint outside Europe. This enables us to better support customers in the Americas with faster delivery and local machine production.

Conclusion

The 2-shot injection molding market continues to gain importance as manufacturers seek efficient ways to produce complex, multi-material components in a single process. This technology supports better product durability, improved design flexibility, and reduced assembly requirements, making it attractive across automotive, medical, electronics, and consumer goods industries.

Growing interest in lightweight parts, ergonomic designs, and high-quality surface finishes further strengthens its relevance. Advances in materials, automation, and precision molding systems are also improving process reliability and scalability. As sustainability and manufacturing efficiency remain key priorities, two-shot injection molding is expected to play a larger role in modern production environments, supporting innovation while helping manufacturers optimize cost, quality, and performance across diverse applications.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)