Table of Contents

Overview

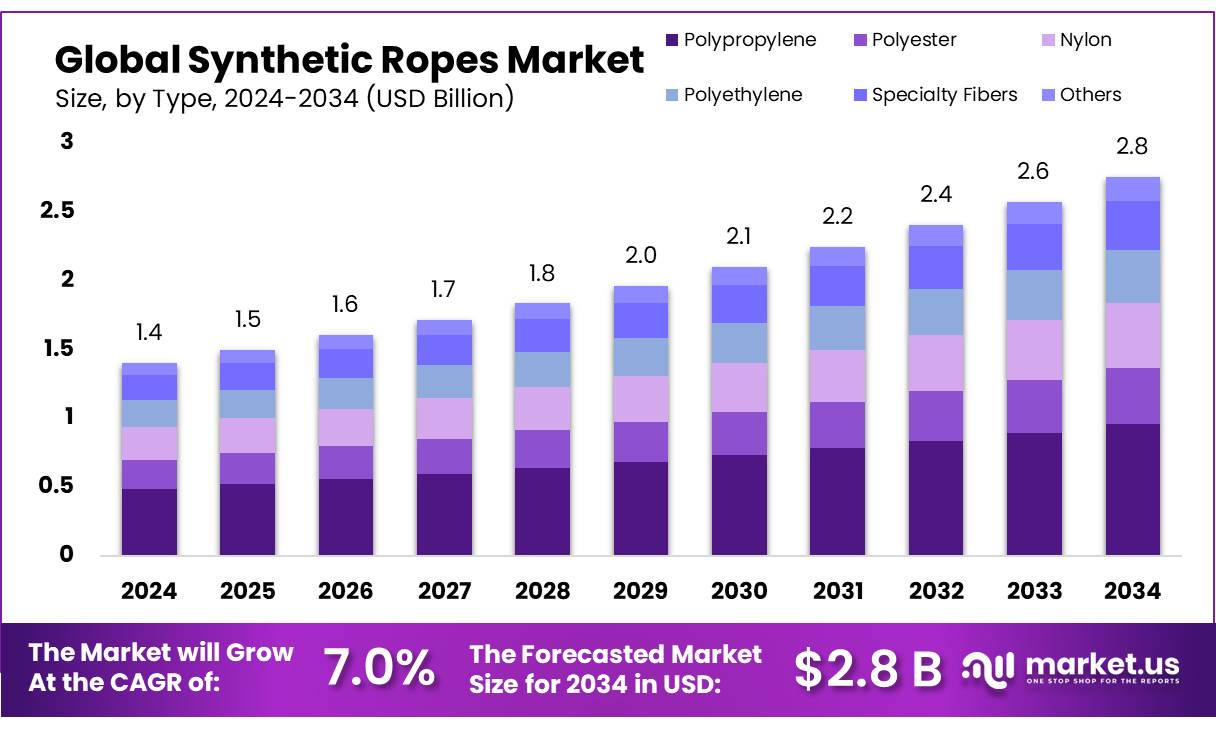

New York, NY – August 05, 2025 – The Global Synthetic Ropes Market is projected to grow from USD 1.4 billion in 2024 to approximately USD 2.8 billion by 2034, achieving a CAGR of 7.0% during the forecast period (2025–2034). In 2024, the Asia-Pacific (APAC) region led the market, commanding a 52.7% share with revenues of USD 0.7 billion.

The synthetic rope concentrate industry focuses on producing high-performance polymer-based fibers, including polypropylene, polyester, nylon, polyethylene, and specialty fibers. These concentrates are critical feedstocks, imparting essential properties like high tensile strength, UV resistance, chemical durability, and abrasion resistance, which enhance the quality and reliability of synthetic ropes.

Synthetic ropes, leveraging these advanced concentrates, are increasingly replacing traditional natural fiber and steel ropes across various sectors. Their lightweight design, combined with superior flexibility and strength, makes them ideal for applications in marine operations, construction, oil and gas, and industrial lifting. The growing emphasis on safety, efficiency, and durability is driving consistent demand for synthetic ropes and their concentrates.

The Indian government is actively supporting the synthetic rope industry through initiatives like the PM MITRA scheme, launched in 2021. This program aims to establish seven integrated textile parks with a total investment of ₹4,445 crore, fostering sustainable development and boosting the global competitiveness of India’s textile sector, including synthetic rope production.

The demand for synthetic ropes is fueled by their exceptional strength-to-weight ratio, durability, and resistance to environmental factors like UV radiation and chemicals. These qualities make them highly suitable for marine and fishing, oil and gas, construction, and sports and leisure applications. Notably, India’s inland waterway and smart port projects drove an 18% year-over-year increase in synthetic rope demand.

Key Takeaways

- The Global Synthetic Ropes Market is projected to reach USD 2.8 billion by 2034, rising from USD 1.4 billion in 2024, with a compound annual growth rate (CAGR) of 7.0% during the forecast period.

- Polypropylene emerged as the leading material type, accounting for over 34.7% of the total synthetic ropes market share globally.

- The Marine & Fishing sector dominated the application segment, representing more than 38.1% of the global market demand for synthetic ropes.

- The Asia-Pacific (APAC) region led the global market with a 52.7% share, amounting to approximately USD 0.7 billion in market value in 2024.

➤ Curious about the content? Explore a sample copy of this report – https://market.us/report/synthetic-ropes-market/request-sample/

Report Scope

| Market Value (2024) | USD 1.4 Billion |

| Forecast Revenue (2034) | USD 2.8 Billion |

| CAGR (2025-2034) | 7.0% |

| Segments Covered | By Type (Polypropylene, Polyester, Nylon, Polyethylene, Specialty Fibers, Others), By End Use (Marine and Fishing, Mining, Oil and Gas, Sports, Building and Construction, Others) |

| Competitive Landscape | Atlantic Braids, Axiom Cordages Limited, Bridon-Bekaert, Cancord Ropes Inc., Cortland International, DSR Corp., English Braids Ltd., Katradis Marine Ropes Ind. S.A., Kennedy Wire Rope & Sling, Koronakis SA, LANEX a.s., MAGENTO, INC., Marlow Ropes, Novatec Braids, Ltd., Parker Hannifin Corporation |

➤ Directly purchase a copy of the report – https://market.us/purchase-report/?report_id=153267

Key Market Segments

Type Analysis

In 2024, polypropylene captured a leading 34.7% share of the global synthetic ropes market, driven by its optimal combination of strength, low weight, and affordability. These attributes make polypropylene ropes highly suitable for marine, fishing, and industrial applications. Their resistance to water, mildew, and most chemicals enhances their appeal for use in harsh outdoor environments, while their buoyancy makes them a top choice for aquaculture and boating.

End-Use Analysis

In 2024, the marine and fishing sector dominated the global synthetic ropes market with a 38.1% share, driven by the expansion of the global fishing industry and robust maritime economies in countries with extensive coastlines. Synthetic ropes, such as those made from polypropylene and polyester, are widely utilized in fishing nets, mooring lines, and towing due to their lightweight nature, resistance to saltwater corrosion, and superior durability compared to traditional materials.

Regional Analysis

In 2024, the Asia-Pacific (APAC) region dominated the global synthetic ropes market, holding a 52.7% share and generating approximately USD 0.7 billion in revenue. This dominance is driven by the region’s thriving maritime economy, rapid industrialization, and strong growth in construction, shipping, and aquaculture.

Key contributors include China, India, Japan, South Korea, and Indonesia, where demand is fueled by expanding port activities, fisheries, and infrastructure projects. China, as the world’s largest fishing nation and a major shipbuilding hub, significantly boosts the consumption of polypropylene and polyester ropes. In India, initiatives like Sagarmala have increased the use of durable synthetic ropes for mooring and towing in coastal shipping and inland waterway projects.

Top Use Cases

- Marine and Fishing Applications: Synthetic ropes, like polypropylene and polyester, are widely used in fishing nets, mooring lines, and towing due to their lightweight nature, resistance to saltwater corrosion, and durability. Their buoyancy and strength make them ideal for aquaculture and boating, reducing downtime and maintenance costs in harsh marine environments.

- Oil and Gas Industry: Synthetic ropes, such as those made from Dyneema and Kevlar, are essential for offshore oil and gas operations. Used in mooring systems, lifting, and towing, they offer high strength-to-weight ratios and resist harsh conditions, making them a reliable choice for deep-sea exploration and heavy-duty applications.

- Construction Sector: In construction, synthetic ropes are used for rigging, lifting, and scaffolding. Their lightweight design and high tensile strength make them easier to handle than steel ropes, improving safety and efficiency. They withstand environmental factors like UV rays and chemicals, ideal for demanding construction sites.

- Sports and Leisure Activities: Synthetic ropes are popular in sports like climbing, sailing, and camping due to their lightweight and durable properties. Nylon and polyester ropes resist abrasion and UV damage, ensuring safety and reliability in outdoor recreational activities where weight and performance are critical.

- Industrial Lifting and Cranes: Synthetic ropes are increasingly used in cranes and industrial lifting for their strength and flexibility. Made from high-performance fibers like UHMWPE, they offer superior load-bearing capacity while being easier to handle, reducing operational risks and enhancing efficiency in heavy-duty lifting tasks.

- Aquaculture and Deep-Sea Fishing: Synthetic ropes, particularly polypropylene, are vital in aquaculture for securing nets and cages. Their water resistance and buoyancy make them perfect for deep-sea fishing, supporting sustainable practices by reducing maintenance needs and ensuring durability in challenging underwater environments.

Recent Developments

1. Atlantic Braids

Atlantic Braids has expanded its high-performance synthetic rope offerings, focusing on marine and industrial applications. Their latest Ultra-High Molecular Weight Polyethylene (UHMWPE) ropes provide superior strength and abrasion resistance. The company has also introduced eco-friendly ropes made from recycled materials, catering to sustainability demands. Atlantic Braids continues to innovate with custom solutions for the offshore and fishing industries.

2. Axiom Cordages Limited

Axiom Cordages has launched Axiom Ultra, a new range of high-modulus synthetic ropes for heavy lifting and mooring. Their recent R&D focuses on hybrid ropes combining Dyneema and polyester for enhanced durability. The company is also expanding into renewable energy, supplying ropes for offshore wind farms. Axiom’s anti-UV and chemical-resistant ropes are gaining traction in the oil & gas sector.

3. Bridon-Bekaert

Bridon-Bekaert has introduced Bridon Dyneema Max, a next-generation synthetic rope for mining and crane operations. Their latest innovation includes smart ropes with embedded sensors for real-time load monitoring. The company is also investing in sustainable production methods, reducing its carbon footprint. Bridon-Bekaert’s ropes are now widely used in deep-sea applications due to their high strength-to-weight ratio.

4. Cancord Ropes Inc.

Cancord Ropes has developed Cancord X-Treme, a lightweight synthetic rope for aerospace and military applications. Their recent collaboration with defense agencies has led to heat-resistant aramid ropes for extreme conditions. The company is also enhancing its marine ropes with improved fatigue resistance, targeting the yacht and shipping industries.

5. Cortland International

Cortland has unveiled Cortland Plasma, a cutting-edge synthetic rope for deepwater oil exploration. Their composite tethers are being used in subsea robotics and renewable energy installations. Cortland is also pioneering AI-driven rope lifecycle prediction to optimize maintenance schedules. The company’s focus on R&D has strengthened its position in high-tech marine and industrial markets.

Conclusion

The Synthetic Ropes Market is experiencing robust growth due to their versatility, lightweight design, and superior strength across diverse applications. From marine and fishing to construction, oil and gas, and renewable energy, these ropes meet industry demands for safety, efficiency, and durability. Ongoing innovations in high-performance fibers and increasing focus on sustainability will continue to drive market expansion, positioning synthetic ropes as a preferred alternative to traditional materials.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)