Table of Contents

Introduction

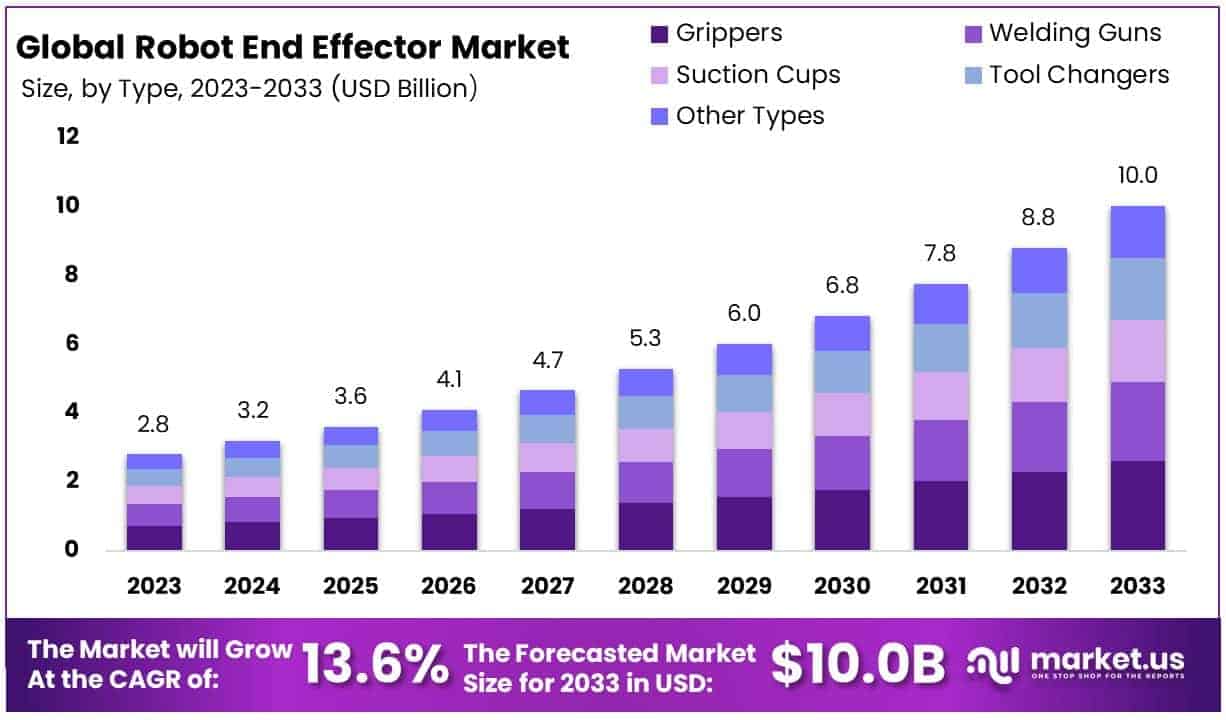

The Global Robot End Effector Market is projected to reach a valuation of approximately USD 10.0 billion by 2033, up from USD 2.8 billion in 2023. This growth reflects a robust compound annual growth rate (CAGR) of 13.60% during the forecast period from 2024 to 2033.

A robot end effector is the component at the end of a robotic arm, designed to interact with the environment. It serves as the “hand” of the robot, performing specific tasks such as gripping, welding, cutting, or painting, depending on its design and purpose. The robot end effector market encompasses the production, development, and distribution of these components across various industries, including manufacturing, healthcare, logistics, and automotive.

This market is witnessing significant growth, driven by advancements in robotics technology, increasing automation across industries, and the rising demand for customized solutions. Factors such as the growing adoption of collaborative robots (cobots) and the integration of AI and IoT in robotics are further fueling demand. Opportunities lie in sectors such as e-commerce and healthcare, where specialized end effectors are critical for handling delicate materials and precision tasks. The market’s expansion is bolstered by global industrial automation trends and emerging economies.

Key Takeaways

- The Robot End Effector Market is projected to grow from USD 2.8 Billion in 2023 to USD 10 Billion by 2033, with a robust CAGR of 13.60%.

- Grippers hold the largest market share at 26%, reflecting their versatility across multiple industries.

- Collaborative Industrial Robots dominate robot types with 56% market share, highlighting the preference for safer and more adaptable automation solutions.

- Handling is the leading application segment, commanding a 37% market share, driven by the widespread need for material handling in industrial processes.

- The Automotive sector leads with a 24% market share, fueled by the industry’s focus on automation to improve efficiency and product quality.

- APAC is the largest regional market, accounting for 32.1% of the market share, powered by manufacturing hubs like China, Japan, and South Korea. North America and Europe hold significant shares of 29% and 27%, respectively.

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2023) | USD 2.8 Billion |

| Forecast Revenue (2033) | USD 10 Billion |

| CAGR (2024-2033) | 13.60% |

| Segments Covered | By Type (Grippers, Welding Guns, Suction Cups, Tool Changers, Other Types), By Robot Type (Traditional Industrial Robots, Collaborative Industrial Robots), By Application (Handling, Welding, Assembly, Processing, Other Applications), By Industry Vertical (Electrical and Electronics, Food & Beverages, Machinery, Automotive, Other Industry Verticals) |

| Competitive Landscape | IBM, Zimmer Group, Festo, Cisco Systems Inc., Huawei Technologies Co., Ltd., Juniper Networks, Inc., Nokia Corporation, Arista Networks, Inc., Palo Alto Networks, Inc., Fortinet, Inc., Other Key Players |

Emerging Trends

- Soft Robotics Integration: There’s a growing shift towards soft robotic end effectors that can handle delicate items without causing damage. This trend is particularly evident in industries like food processing and electronics assembly, where gentle handling is crucial.

- Modular and Reconfigurable Designs: Developments in modular end effectors allow robots to adapt to various tasks by changing their gripping mechanisms. This flexibility enhances efficiency in dynamic manufacturing settings.

- Enhanced Sensing Capabilities: Incorporating advanced sensors into end effectors enables robots to better perceive their environment, improving precision in tasks like assembly and quality control. This advancement is crucial for applications requiring high accuracy.

- Biohybrid Robotics: The fusion of biological components with robotic systems is an emerging field. For instance, using living organisms as end effectors can offer unique adaptability and efficiency in specific applications.

- AI and Machine Learning Integration: End effectors are increasingly being equipped with AI and machine learning capabilities, allowing them to learn from interactions and improve performance over time. This development is enhancing the adaptability and efficiency of robotic systems.

Top Use Cases

- Material Handling in Warehouses: Robotic end effectors are extensively used for picking and placing items in warehouses. They can handle a wide range of products, improving efficiency and reducing human labor. For example, Amazon employs robots equipped with end effectors to handle millions of items daily.

- Precision Assembly in Electronics Manufacturing: In the electronics industry, end effectors are used for assembling small components with high precision. This application enhances production speed and product consistency. Companies like Foxconn utilize robotic end effectors in assembling smartphones and other electronics.

- Automated Welding in Automotive Production: End effectors equipped with welding tools are employed in automotive manufacturing to perform precise and consistent welds. This automation improves production rates and weld quality. Major automotive manufacturers use robotic welding extensively in their assembly lines.

- Food Processing and Packaging: In the food industry, end effectors handle tasks such as sorting, packaging, and cutting. For instance, robotic arms with specialized end effectors can process up to 150 items per minute, enhancing efficiency and hygiene.

COURIER MAIL - Medical Rehabilitation Assistance: Robotic end effectors are used in rehabilitation to assist patients with exercises. These devices can provide precise movements, aiding in patient recovery. Studies have shown that patients using robotic assistance can achieve up to 30% faster recovery times.

Major Challenges

- Limited Dexterity and Adaptability: Achieving human-like dexterity in end effectors remains a significant challenge. Current designs often struggle with tasks requiring fine manipulation, limiting their application scope.

- Integration with Existing Systems: Incorporating advanced end effectors into existing robotic systems can be complex and costly. Compatibility issues may arise, necessitating additional investments in system upgrades.

- High Development and Maintenance Costs: Developing sophisticated end effectors with advanced sensing and adaptability features can be expensive. Additionally, maintenance costs may be high due to the complexity of these devices.

- Durability and Reliability Concerns: Ensuring that end effectors can withstand harsh industrial environments without frequent failures is challenging. Durability issues can lead to increased downtime and maintenance expenses.

- Safety and Compliance Standards: Meeting stringent safety regulations, especially in collaborative environments where robots work alongside humans, is essential. Ensuring end effectors comply with these standards adds to the design complexity.

Top Opportunities

- Advancements in Soft Robotics: Developing soft robotic end effectors can open new applications in handling delicate and irregularly shaped objects, particularly in the food and agriculture industries.

- Expansion in E-commerce Fulfillment: The growth of e-commerce presents opportunities for end effectors in automated warehouses, enhancing order fulfillment speed and accuracy.

- Adoption in Healthcare and Rehabilitation: End effectors designed for medical applications can assist in surgeries and patient rehabilitation, improving healthcare outcomes.

- Integration with AI for Enhanced Capabilities: Combining end effectors with artificial intelligence can lead to smarter robots capable of learning and adapting to complex tasks, broadening their application scope.

- Development of Modular End Effectors: Creating modular end effectors that can be easily reconfigured for different tasks offers flexibility and cost savings in various industrial applications.

Key Player Analysis

- ABB Ltd. is a leading player in the robot end-effector market, offering a comprehensive range of robotic solutions, including grippers and welding guns. The company’s strong presence in the automation sector and continuous innovation have solidified its position as a key contributor to market growth.

- Schunk GmbH & Co. KG specializes in clamping technology and gripping systems, providing high-quality end effectors that enhance robotic precision and efficiency. Their commitment to research and development has enabled them to introduce advanced products catering to diverse industrial applications.

- Festo AG & Co. KG is renowned for its pneumatic and electrical automation technology, including a variety of end effectors like grippers and suction cups. Festo’s solutions are widely adopted in industries such as automotive and electronics, contributing significantly to the market’s expansion.

- KUKA AG offers a broad spectrum of robotic end effectors designed for tasks ranging from handling to welding. Their integration of cutting-edge technology and focus on customer-specific solutions have reinforced their status as a prominent market player.

- Zimmer Group provides a diverse portfolio of end-of-arm tooling, including grippers and tool changers, known for their durability and precision. Their emphasis on innovation and quality has enabled them to maintain a strong foothold in the competitive landscape of the robot end-effector market.

Regional Analysis

Asia-Pacific: Lead Region in Robot End Effector Market with Largest Market Share of 32.1%

The Asia-Pacific region emerges as the leading market for robot end effectors, holding the largest market share of 32.1% in 2023 and contributing significantly to the global industry with an estimated market size of USD 0.8 billion. This dominance is primarily driven by the region’s rapid industrialization, the extensive adoption of robotics in manufacturing, and favorable government initiatives supporting automation across key economies such as China, Japan, and South Korea. The presence of a robust electronics and automotive manufacturing sector further accelerates demand for advanced robotic solutions, solidifying Asia-Pacific’s position as the top-performing region in the robot end effector market.

Recent Developments

- In 2024, Soft Robotics Inc. transitioned its gripper business assets to the Schmalz Group in a confidential transaction. The company rebranded as Oxipital AI, aiming to bring advanced AI innovations to essential industries.

- In August 2024, Symbotic Inc. (Nasdaq: SYM), a pioneer in AI-based robotics for supply chain automation, acquired key assets of Veo Robotics, including its FreeMove® 3D vision system for industrial applications. This integration is expected to improve collaborative efficiency between humans and machines in warehouses.

- In 2023, PULS expanded its portfolio by acquiring the wireless charging division of Wiferion, previously owned by Tesla. PULS intends to continue delivering Wiferion’s products globally while advancing its technology.

- In 2024, One Equity Partners secured a majority stake in Comau S.p.A., with Stellantis maintaining a minority role. Comau’s focus on industrial automation and robotics is set to benefit from this strategic partnership.

- In June 2024, igus® increased its capabilities by acquiring a majority share in Atronia Tailored Sensing, a company specializing in sensors for smart plastics. This move aligns with igus’ vision to scale Industry 4.0 technologies and make them accessible to a broader market.

Conclusion

The robot end effector market is poised for substantial growth, driven by increasing automation across various industries and technological advancements enhancing robotic capabilities. The integration of AI and machine learning is enabling more adaptable and intelligent end effectors, while the development of soft robotics is expanding applications in sectors requiring delicate handling. Despite challenges such as high initial investments and the need for skilled personnel, the market offers significant opportunities, particularly in emerging economies and industries like e-commerce and healthcare. As industries continue to seek efficiency and precision, the demand for advanced robot end effectors is expected to rise, contributing to the market’s dynamic expansion.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)