Table of Contents

Introduction

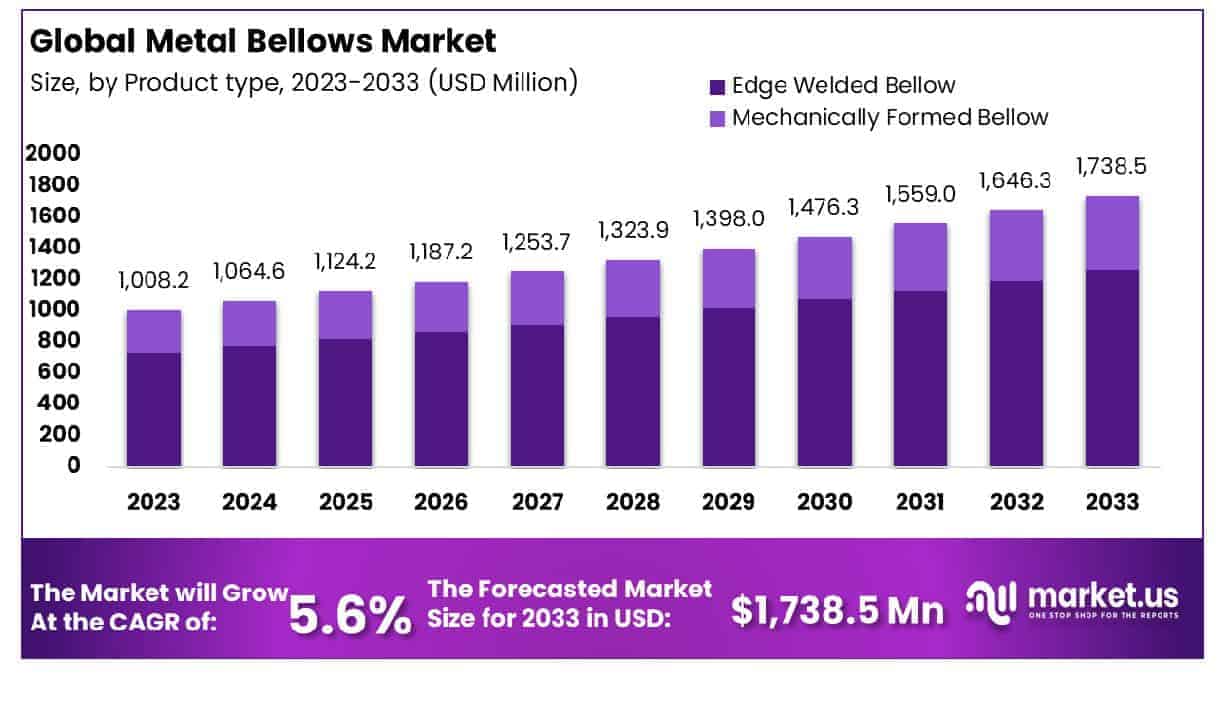

The Global Metal Bellows Market is projected to reach USD 1,738.5 million by 2033, up from USD 1,008.2 million in 2023, with a compound annual growth rate (CAGR) of 5.60% during the forecast period from 2024 to 2033.

The metal bellows market refers to the sector involved in the manufacturing and distribution of flexible, metallic components designed to absorb movement, accommodate thermal expansion, and provide sealing in a variety of mechanical systems. These bellows are primarily used in industries such as aerospace, automotive, oil and gas, and chemical processing, where precision and reliability are crucial. The market has seen consistent growth driven by increasing demand for high-performance seals and flexible couplings, particularly in harsh environments.

Factors fueling this growth include the ongoing advancements in industries like aerospace and automotive, where there is a growing need for components that can withstand extreme conditions, high pressures, and corrosive environments. Additionally, the rising trend of industrial automation, coupled with demand for high-quality, durable, and cost-effective solutions, presents a significant opportunity for market expansion. As industries continue to innovate, the metal bellows market is poised to experience substantial growth, driven by technological advancements and rising industrial applications.

Key Takeaways

- The Metal Bellows Market is expected to reach USD 1,738.5 million by 2033, growing from USD 1,008.2 million in 2023, at a CAGR of 5.60% during the forecast period from 2024 to 2033.

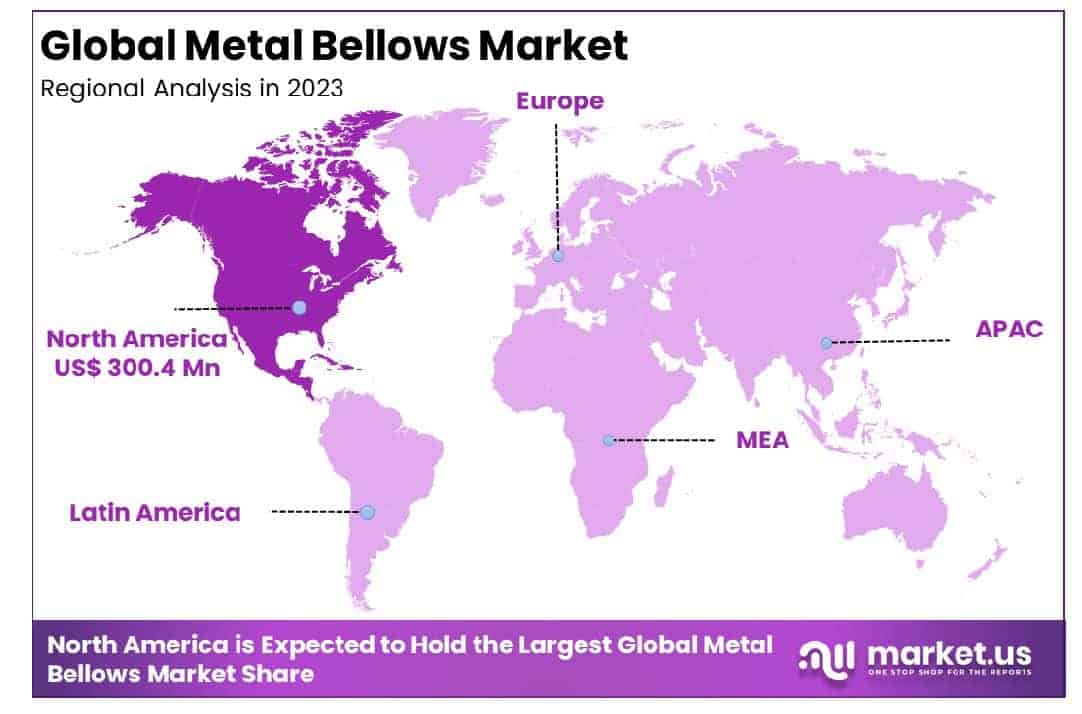

- North America leads the global market, holding a significant 29.8% market share.

- Edge-welded bellows are the market leaders, accounting for 72.7% of the total market share.

- Titanium alloys dominate the material market, comprising 61.3% of the share.

- The aerospace industry is a major consumer of metal bellows, holding 25.8% of the market share.

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2023) | USD 1,008.2 Million |

| Forecast Revenue (2033) | USD 1,738.5 Million |

| CAGR (2024-2033) | 5.60% |

| Segments Covered | By Product Type(Edge-Welded, Mechanically formed), By Material Type(Titanium alloys, Stainless steel, Beryllium Copper, Nickel Alloys), By End User(Automotive, Aerospace, Oil & gas, Electronics, Power generation, Medical) |

| Competitive Landscape | Servometer, EnPro Industries Inc, EagleBurgmann KE, Meggitt Plc, USA Bellows, Inc, KSM Corporation, Technoflex Corporation, BOA Holding GmbH, Freudenberg Group, MW Industries, Smith Group, Pebiflex |

Emerging Trends

- Miniaturization: There’s a growing trend for smaller, more compact bellows used in highly sensitive environments such as microelectronics and precision equipment.

- Customization: Increasing demand for custom-made metal bellows to meet the specific needs of clients, particularly in sectors like aerospace and medical devices.

- Advanced Materials: The use of advanced alloys such as Inconel and Hastelloy is rising due to their superior strength and resistance to high temperatures and corrosion.

- 3D Printing: Adoption of 3D printing for creating complex bellow structures, allowing for faster production cycles and cost reduction in prototyping.

- Integration with IoT: Increasing integration of IoT technologies for predictive maintenance and monitoring of systems using metal bellows, ensuring longer life and better performance.

Top Use Cases

- Aerospace & Defense: Metal bellows are used in aircraft fuel lines and hydraulic systems to absorb shocks and vibrations, ensuring system stability.

- Automotive: Employed in exhaust systems and suspension components to manage vibrations and thermal expansion.

- Industrial Applications: Common in heavy machinery and manufacturing plants, where they are used in expansion joints, pressure seals, and as flexible connectors.

- Oil & Gas: Metal bellows are crucial in offshore drilling operations, where they prevent leakage and allow for safe fluid transfer under high pressure.

- Medical Devices: Used in life-support equipment like ventilators and drug delivery systems, where precise sealing is critical for operation.

Major Challenges

- Cost of Raw Materials: Fluctuating prices of metals such as stainless steel and titanium can make the production of metal bellows more expensive.

- Manufacturing Complexity: The manufacturing process of metal bellows requires high precision and specialized equipment, which can be challenging for some manufacturers.

- Corrosion Resistance: Despite their durability, metal bellows may suffer from wear and corrosion over time, particularly in highly aggressive environments.

- Strict Regulatory Standards: Industries like aerospace, medical, and automotive have stringent safety regulations that manufacturers must adhere to, complicating the design and production processes.

- Market Competition: The increasing number of manufacturers in the market can drive price wars, reducing profit margins for some players.

Top Opportunities

- Automated Manufacturing: Advances in robotics and automation could streamline the production of metal bellows, reducing labor costs and increasing efficiency.

- Emerging Markets: Expanding industrialization in developing countries provides new opportunities for metal bellows in sectors such as automotive, oil and gas, and manufacturing.

- High-Performance Alloys: The ongoing development of new materials with superior properties can open up new avenues for metal bellows in demanding industries like aerospace and energy.

- Sustainability Trends: Growing awareness of environmental issues has created opportunities for companies to develop recyclable metal bellows, catering to eco-conscious markets.

- Customized Solutions: As industries move towards more specialized and niche applications, the demand for custom metal bellows that meet specific requirements is expected to rise.

Key Player Analysis

The Global Metal Bellows Market in 2024+ features several key players driving innovation and growth. Servometer leads with precision-engineered products, while EnPro Industries Inc. capitalizes on opportunities in automotive and energy. EagleBurgmann KE specializes in high-quality sealing solutions, and Meggitt Plc focuses on aerospace applications with advanced materials. USA Bellows, Inc. excels in custom solutions, and KSM Corporation and Technoflex Corporation offer durable and cost-effective bellows. BOA Holding GmbH and Freudenberg Group are known for corrosion-resistant, high-temperature solutions, while MW Industries and Smith Group provide high-performance systems. Pebiflex remains a niche player with tailored bellow systems. These companies continue to innovate and expand to meet growing market demand.

Market Key Players

- Servometer

- EnPro Industries Inc

- EagleBurgmann KE

- Meggitt Plc

- USA Bellows, Inc

- KSM Corporation

- Technoflex Corporation

- BOA Holding GmbH

- Freudenberg Group

- MW Industries

- Smith Group

- Pebiflex

Regional Analysis

North America dominates the global metal bellows market, accounting for 29.8% of the market share in 2023, with a market value of USD 300.4 Million. This region’s dominance is driven by a robust demand across key industries such as aerospace, automotive, oil & gas, and HVAC, where metal bellows are crucial for their flexibility, durability, and resistance to high temperatures and pressure variations.

The United States remains the leading contributor, supported by its advanced manufacturing capabilities, extensive industrial infrastructure, and increasing adoption of precision engineering solutions. Furthermore, the growing trend toward automation and the expansion of the energy sector continue to propel the demand for metal bellows in North America. As a result, the region is expected to maintain its leadership position throughout the forecast period.

Conclusion

The metal bellows market is set for sustained growth, driven by increasing demand across various high-performance industries, including aerospace, automotive, oil and gas, and medical devices. As industries continue to evolve with advancements in technology, particularly in automation and materials science, the need for flexible, durable, and customizable solutions will only intensify. While challenges such as raw material costs, manufacturing complexity, and corrosion resistance remain, the market offers substantial opportunities, particularly in emerging economies and with innovations in high-performance alloys and eco-friendly solutions. Companies that can adapt to these trends, focusing on quality, customization, and efficiency, will be well-positioned to capitalize on the expanding market potential.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)