Table of Contents

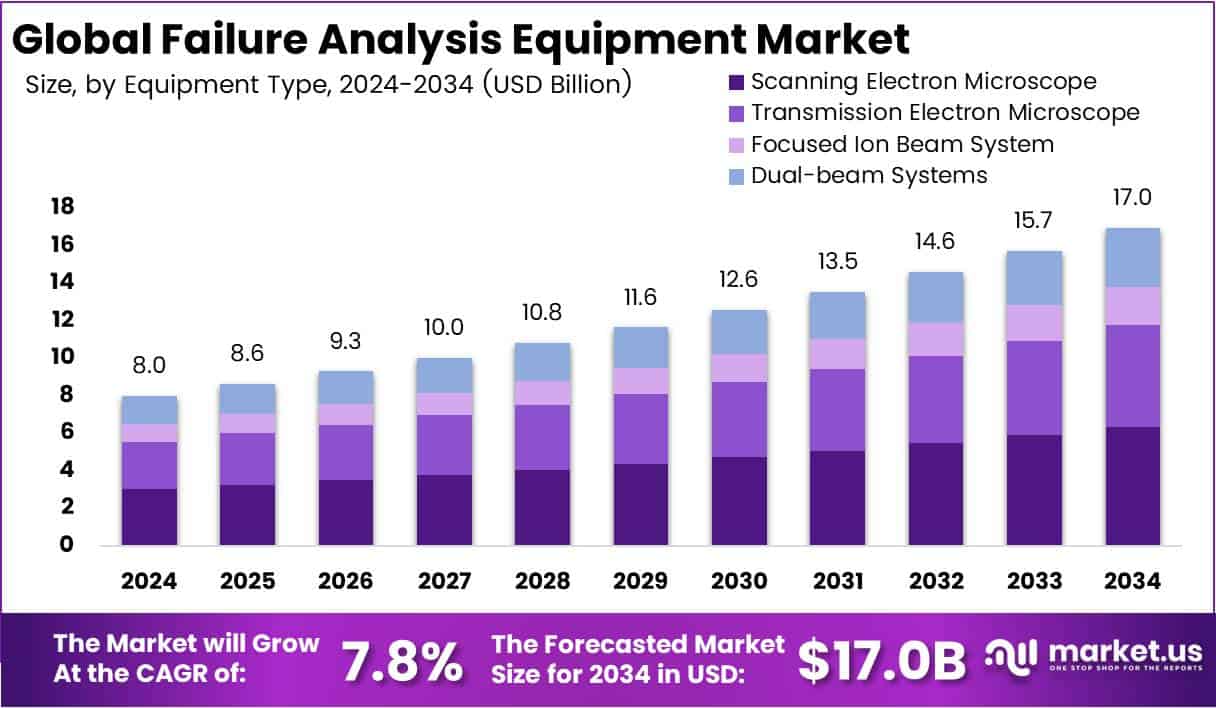

The global Failure Analysis Equipment Market is projected to experience significant growth, expanding from USD 8.0 billion in 2024 to USD 17.0 billion by 2034, at a compound annual growth rate (CAGR) of 7.8%. This growth is driven by increasing demands for product quality assurance, technological advancements, and the rising complexity of electronic devices.

Failure analysis equipment plays a crucial role in diagnosing and understanding the root causes of failures in electronic components and systems. These tools are pivotal in industries such as semiconductors, automotive, aerospace, and telecommunications, where reliability and performance are critical.

The market’s expansion reflects the growing emphasis on quality control and the need for precise diagnostic tools to ensure the integrity of complex systems.

Key Market Segments

Equipment Types

- Scanning Electron Microscope (SEM): Leading the market with a 37.5% share in 2024, SEMs are favored for their high-resolution imaging capabilities, allowing detailed examination of microstructures.

- Focused Ion Beam (FIB) Systems: These systems are crucial for sample preparation and circuit editing, offering precision in modifying and analyzing microelectronic devices.

- Atomic Force Microscopes (AFM): AFMs provide topographical data at the nanoscale, essential for understanding surface characteristics and mechanical properties.

- X-ray Inspection Systems: Utilized for non-destructive testing, these systems enable the visualization of internal structures without damaging the sample.

Technologies

- Broad Ion Milling (BIM): Dominating the technology segment with a 38.4% share in 2024, BIM is preferred for its precision in sample preparation, facilitating accurate analysis.

- Plasma FIB: Combining the capabilities of FIB with plasma etching, this technology enhances the efficiency of sample preparation and analysis.

- Laser Ablation: Employed for material removal and analysis, laser ablation offers high precision and minimal sample contamination.

- Microtomy: A technique used for slicing samples into ultra-thin sections, essential for detailed examination under electron microscopes.

End-User Industries

- Semiconductors: The largest segment, driven by the need for rigorous testing and quality assurance in chip manufacturing.

- Automotive: With the rise of electric vehicles and advanced driver-assistance systems, failure analysis ensures the reliability and safety of components.

- Aerospace & Defense: Critical applications demand the highest standards of reliability, making failure analysis indispensable.

- Telecommunications: Ensuring the performance and longevity of communication equipment through detailed failure analysis.

- Consumer Electronics: Addressing the challenges of miniaturization and complexity in modern electronic devices.

Regional Insights

Asia Pacific leads the global failure analysis equipment market, driven by major semiconductor hubs in countries like China, Japan, South Korea, and Taiwan. The region accounted for 43.8% of the global market share in 2024, valued at USD 3.5 billion. Strong investments in electronics, automotive innovation, and materials research, along with rapid industrialization and advanced research labs, are fueling steady growth.

Market Drivers

- Technological Advancements: Innovations in microscopy and imaging technologies enhance the capabilities of failure analysis equipment, enabling more precise and efficient diagnostics.

- Miniaturization of Components: As electronic components become smaller and more complex, the demand for advanced failure analysis tools increases to ensure their reliability.

- Quality Assurance Demands: Industries are placing greater emphasis on quality control to meet regulatory standards and consumer expectations, driving the need for effective failure analysis.

- Rising Complexity of Electronic Devices: The integration of multiple functionalities into single devices necessitates thorough testing and analysis to identify potential failure points.

Market Challenges

- High Equipment Costs: The sophisticated nature of failure analysis equipment results in significant capital expenditure, which can be a barrier for smaller enterprises.

- Skilled Workforce Requirement: Operating advanced failure analysis tools requires specialized knowledge and training, posing a challenge in terms of workforce development.

- Maintenance and Calibration: Ensuring the accuracy and longevity of equipment necessitates regular maintenance and calibration, adding to operational costs.

Competitive Landscape

The failure analysis equipment market is characterized by the presence of several key players offering a range of products and solutions. Companies are focusing on technological innovations, strategic partnerships, and regional expansions to strengthen their market positions. The competitive dynamics are influenced by factors such as product differentiation, pricing strategies, and customer service excellence.

Future Outlook

The failure analysis equipment market is poised for continued growth, driven by technological advancements and the increasing complexity of electronic systems. As industries strive for higher reliability and performance standards, the demand for advanced failure analysis tools is expected to rise, presenting opportunities for innovation and market expansion.

Conclusion

In conclusion, the failure analysis equipment market is integral to ensuring the reliability and performance of electronic systems across various industries. With ongoing technological advancements and a focus on quality assurance, the market is set to experience sustained growth in the coming years.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)