Table of Contents

Introduction

The Global Circular Saw Blade Market is projected to reach approximately USD 17.4 billion by 2033, up from USD 11.2 billion in 2023, growing at a compound annual growth rate (CAGR) of 4.50% from 2024 to 2033.

The circular saw blade market encompasses the manufacturing, distribution, and consumption of circular saw blades, which are essential tools used in cutting various materials such as wood, metal, plastic, and stone. These blades, characterized by their round shape and toothed edges, are widely used in industries ranging from construction to woodworking, metalworking, and manufacturing. The market is experiencing growth driven by several factors, including the rise in construction and infrastructure development, particularly in emerging economies.

The increasing demand for power tools, particularly in DIY and professional sectors, further accelerates the market’s expansion. Additionally, technological advancements in blade design and materials have led to blades that offer greater efficiency, durability, and precision, enhancing their appeal across various applications. The market also presents significant opportunities due to the rising trend of automation in industrial settings, the growing focus on sustainable materials, and the increasing adoption of advanced cutting tools in niche markets such as aerospace and automotive manufacturing.

Key Takeaways

- The global circular saw blade market is expected to reach USD 17.4 billion by 2033, up from USD 11.2 billion in 2023, reflecting a steady CAGR of 4.50% from 2024 to 2033. This growth is driven by expanding industrial applications and technological advancements in cutting tools.

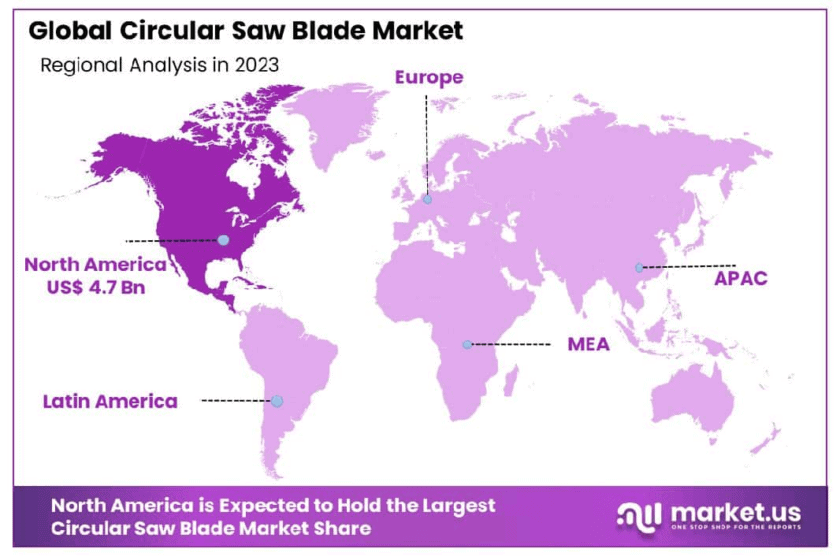

- North America holds the largest share of the market, accounting for 41.7%. This dominance is attributed to the region’s advanced manufacturing sectors, increased construction activities, and high demand for precision cutting tools.

- Carbide saw blades continue to lead the market, representing 55.2% of the total market share. Their popularity is due to their durability, efficiency, and ability to handle tough materials, making them the preferred choice for heavy-duty cutting applications.

- Stone cutting is the leading application segment, capturing 41.2% of the market share. This reflects sustained demand from construction, mining, and stone processing industries, where high-performance cutting tools are essential for precision and productivity.

Report Scope

| Report Features | Description |

|---|---|

| Market Value (2023) | USD 11.2 Billion |

| Forecast Revenue (2033) | USD 17.4 Billion |

| CAGR (2024-2033) | 4.50% |

| Segments Covered | By Type(Carbide Saw Blades, Diamond Saw Blades, Others), By Application(Stone Cutting, Metal Materials Cutting, Wood Cutting) |

| Competitive Landscape | Freud SpA, Robert Bosch GmbH, Stanley Black and Decker, Tenryu Saw Mfg. Co. Ltd., Hilti Corporation, DEWALT, STARK SpA, Tangshan Metallurgical Saw Blade, General Saw, Lenox, HUANGHE WHIRLWIND, BOSUN |

Circular Saw Blade Statistics

- Around 16.5% of injuries caused by circular saws result in 57% of amputations.

- In 2023, the circular saw market consists of 2,838 buyers and 2,357 suppliers across 209 and 18 countries, respectively.

- Volza’s 2023 Global Reports show 179.7K shipments involving 2,457 buyers and 2,020 suppliers in the circular saw market.

- In 2023, the top five players—Bosch, Makita, Dewalt, Ryobi, and Milwaukee—control around 64% of the market share.

- China dominates the corded circular saw market with a 64% share.

- Carbide saw blades make up 55.2% of the market share by type in 2023.

- Stone cutting applications represent 41.2% of the circular saw market share by application.

- The U.S. Woodworking Machinery Manufacturing industry employed approximately 3,063 people in 2023.

- In 2023, 62% of U.S. woodworking manufacturers invested in robotics and automation.

- Additionally, 60% of manufacturers in the U.S. woodworking industry invested in data analytics, and 39% in the Internet of Things (IoT) in 2023.

Advantages of Circular Saw Machines

- Provides high accuracy and superior surface quality, ideal for cutting high-quality materials.

- Offers a long service life with minimal maintenance costs.

- Available in various specifications to meet different cutting needs at Zeal Tech Automation.

- Built to withstand extreme working conditions, making them suitable for both indoor and outdoor use.

- Some models are designed with low operational noise for a quieter working environment.

Top Use Cases

- Woodworking and Carpentry: Circular saw blades are essential for cutting various types of wood, including plywood, MDF, and hardwoods. Their ability to produce straight, precise cuts makes them a staple in both professional carpentry and DIY woodworking projects. With their versatility, they are used for tasks such as cross-cutting, ripping, and trimming, offering fast and accurate performance.

- Metal Cutting: Circular saw blades with special carbide-tipped teeth or high-performance coatings are often used in metal cutting applications. These blades are ideal for cutting materials like steel, aluminum, and other non-ferrous metals. The ability to handle high temperatures and maintain sharpness even after extended use is crucial in industries such as automotive, construction, and manufacturing, where precision and durability are needed.

- Masonry and Concrete Cutting: For tough materials such as concrete, brick, and stone, circular saw blades equipped with diamond segments are used. These blades are engineered to withstand the abrasiveness of these materials and provide a clean, efficient cut. They are commonly used in construction, renovation, and demolition projects where reliable, high-performance cutting tools are required to handle demanding surfaces.

- Plastic and PVC Cutting: Circular saw blades with fine teeth or special coatings can be used to cut plastics and PVC pipes, which are prevalent in industries such as plumbing, electrical work, and manufacturing. These specialized blades offer smooth, clean cuts without melting or damaging the material. As the demand for plastic products continues to grow, so does the need for reliable cutting solutions like circular saw blades for plastics.

- DIY and Home Renovation: Circular saw blades are widely used in DIY home improvement projects, including flooring, panel cutting, and general repairs. These blades are appreciated for their affordability, ease of use, and ability to deliver consistent results. Home renovation trends continue to increase, with circular saw blades being one of the most accessible tools for homeowners looking to undertake their own improvement tasks.

Major Challenges

- Blade Wear and Dulling: One of the most common challenges with circular saw blades is wear and dulling. As blades are used over time, their cutting edges become less sharp, leading to reduced cutting efficiency and increased friction. This issue is especially prominent when cutting harder materials like metal or concrete, necessitating more frequent blade maintenance or replacement.

- Overheating and Blade Distortion: During prolonged or heavy cutting operations, circular saw blades can overheat, particularly when cutting dense materials. Overheating can cause the blade to warp, distort, or even crack, compromising its effectiveness and safety. Proper cooling techniques or intermittent cutting intervals are required to prevent excessive heat buildup and preserve the blade’s integrity.

- Vibration and Operator Comfort: Vibration from the circular saw can cause discomfort or fatigue for the operator, particularly during extended use. Prolonged exposure to vibration can also lead to long-term physical issues, such as hand-arm vibration syndrome (HAVS), which affects the nerves and blood vessels in the hands and arms. This is a major concern in industries with high tool usage, such as construction and woodworking.

- Material Compatibility: Circular saw blades are not always compatible with every material. A blade designed for cutting wood, for instance, may not perform well when used on metal or masonry. Misusing the blade can lead to poor cutting results, unnecessary wear, and even safety risks. To achieve optimal performance, the appropriate blade must be chosen for each material type, adding to operational complexity.

- Safety Risks and Accidents: Circular saw blades are dangerous tools that, if not handled correctly, can cause serious accidents such as cuts, kickbacks, and even fatal injuries. Safety risks increase if the blade is used improperly or if the operator lacks the proper training. Safety measures, such as blade guards, gloves, and eye protection, are necessary to mitigate the risk of injury.

Regional Analysis

North America Circular Saw Blade Market with Largest Market Share of 41.7%

The North American circular saw blade market is the dominant region, holding a substantial share of 41.7% in 2023, valued at USD 4.7 billion. This market leadership can be attributed to the strong demand for high-quality cutting tools across diverse industries such as construction, automotive, and woodworking. The region benefits from the presence of well-established manufacturers, advanced technological innovations, and robust infrastructure that supports the growth of the market.

Additionally, the increasing adoption of automated machinery in industrial applications and the expansion of the construction sector further bolster the demand for circular saw blades. The U.S. stands out as the largest contributor, driven by a significant number of end-users in manufacturing and heavy industries, making North America the leading market globally. This regional dominance is expected to continue with steady growth due to ongoing investments in industrial expansion and technological advancements in cutting tool designs.

Recent Developments

- In February 2024, Stanley Black & Decker (NYSE: SWK) reported its financial results for the fourth quarter and full year of 2023. Full-year revenues reached $15.8 billion, with fourth-quarter revenues at $3.7 billion, a decline primarily driven by reduced Outdoor and DIY volumes and infrastructure customer destocking. The company posted a fourth-quarter gross margin of 29.6%, reflecting a 10.7-point improvement compared to the previous year. While the GAAP EPS for the quarter was ($1.84), the adjusted EPS was $0.92. Stanley Black & Decker also announced plans to divest its STANLEY Infrastructure business for $760 million in cash and forecasted a full-year diluted GAAP EPS of $1.60 to $2.85 for 2024.

- In October 2023, James Jones & Sons Ltd announced the acquisition of Lancashire Saws Ltd, a leading manufacturer of bandsaw blades. This acquisition strengthens their long-term partnership and positions both companies for future growth.

- In 2024, LEUCO introduced a groundbreaking technology in the woodworking industry with its new diamond-tipped conical saw blades. These enhanced blades offer improved durability, allowing for more frequent resharpening without compromising cutting performance, making them ideal for precision cutting in horizontal panel sizing saws.

- On May 15, 2024, Makita U.S.A., Inc. unveiled a new line of diamond blades designed for battery-powered grinders and power cutters. These blades feature an ultra-thin kerf and a redesigned cutting surface, enhancing cutting speed, blade longevity, and increasing the number of cuts per charge.

- In October 2024, Bosch Power Tools expanded its range of cordless 18V tools by introducing new products tailored for multiple trade industries. These additions include tools for carpentry, electrical work, and for the first time, plumbing, reinforcing Bosch’s commitment to offering versatile solutions for various professional needs.

Conclusion

The global circular saw blade market is witnessing robust growth, driven by advancements in technology, increased industrial applications, and the rising demand for precision cutting tools. As industries such as construction, woodworking, and manufacturing continue to expand, the need for durable, efficient, and versatile cutting solutions will remain strong. While challenges like blade wear, overheating, and safety concerns persist, ongoing innovations in blade design and material technology are addressing these issues, offering more efficient and longer-lasting products. The growing adoption of circular saw blades across various sectors, coupled with a shift towards automation, positions the market for sustained growth in the coming years, making it a key area of interest for manufacturers, suppliers, and end-users alike.

Discuss your needs with our analyst

Please share your requirements with more details so our analyst can check if they can solve your problem(s)